Tube shape investigation in a shell and tube heat exchanger with hybrid nanofluid flow

$180.00 $90.00 Student Discount

- This project aims to evaluate the impact of tube geometry and nanofluid composition on heat transfer performance.

- Three nanofluid compositions are examined: Alumina/water, MWCNT/water, and a hybrid Alumina-MWCNT/water nanofluid.

- It explores two geometric configurations: circular and diamond-shaped tubes’ effect on heat transfer performance.

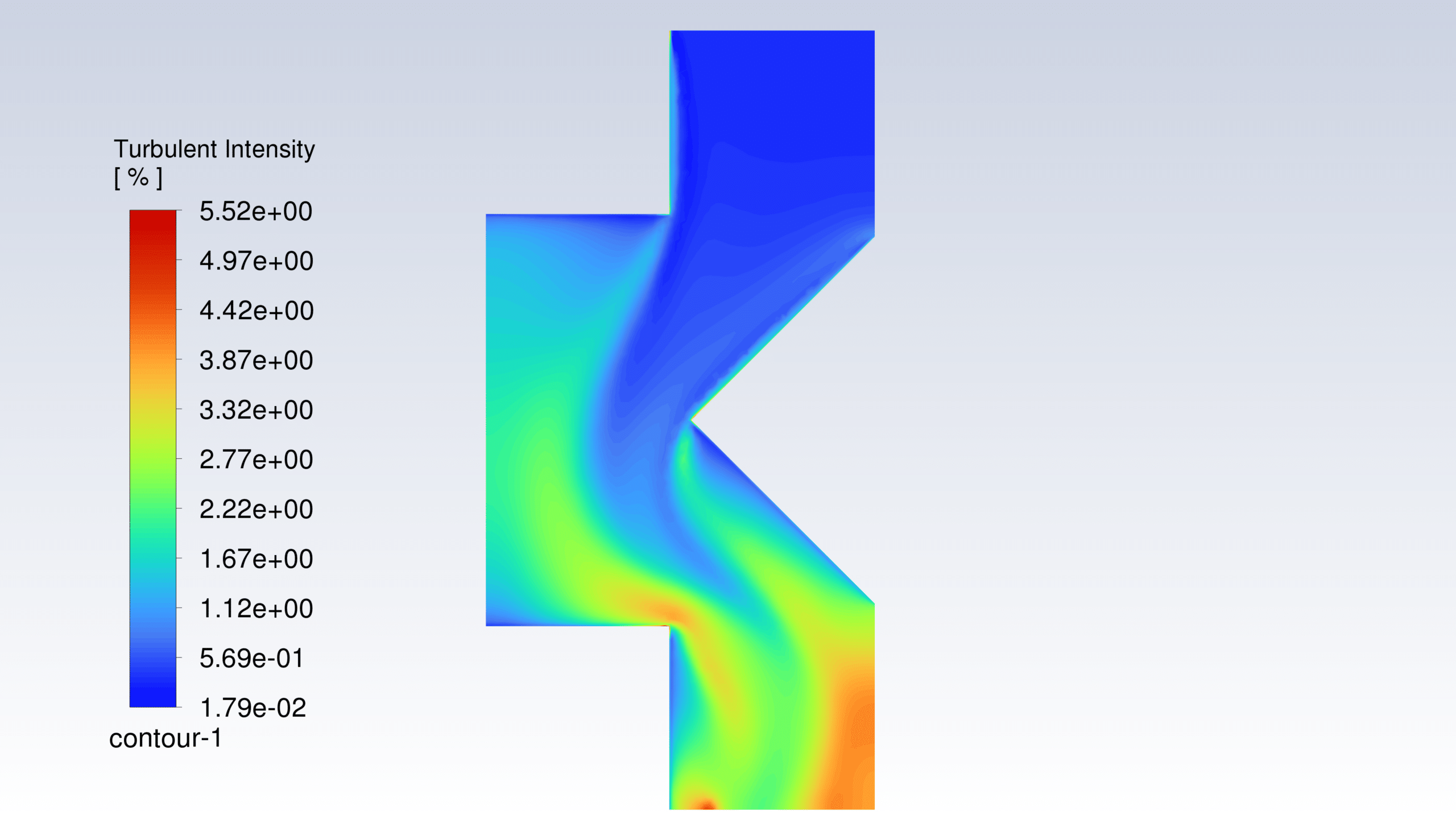

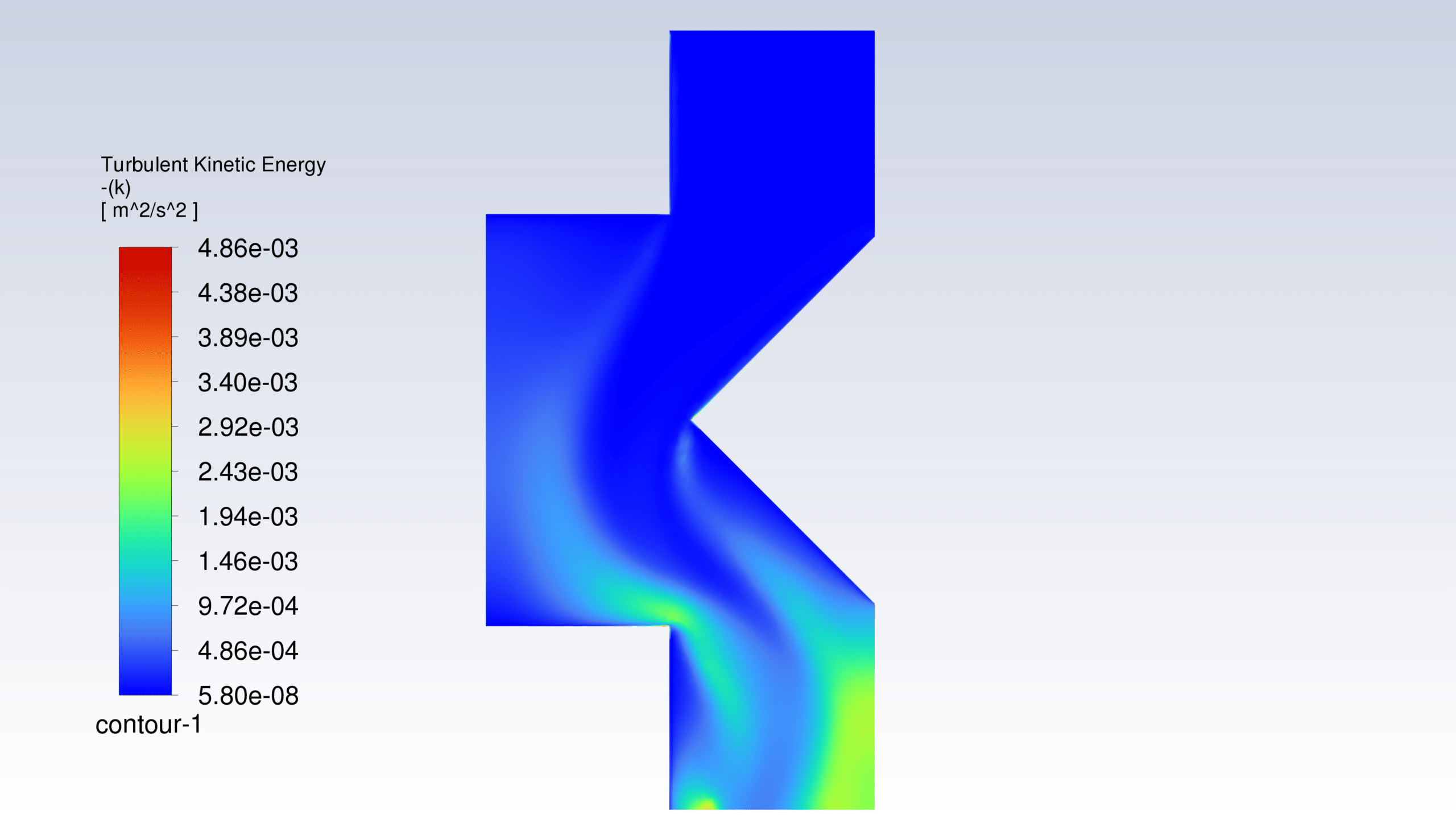

- The turbulence of the flow is simulated by Realizable k-epsilon model.

- The single phase model is considered to simulate nanoparticle presence in the base fluid.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Tube shape investigation in a shell and tube heat exchanger with hybrid nanofluid flow CFD simulation, ANSYS Fluent

Description

This study investigates the heat transfer and various nanofluids in a shell and tube heat exchanger using ANSYS Fluent software. This project aims to evaluate the impact of tube geometry and nanofluid composition on heat transfer performance in which it explores two geometric configurations: circular and diamond-shaped tubes. The geometry of heat exchanger tubes plays a crucial role in determining overall thermal performance and efficiency. While circular tubes are conventional and widely used due to their simplicity and ease of manufacture, there is growing interest in exploring alternative geometries to enhance heat transfer characteristics. Among these, diamond-shaped tubes have emerged as a promising option. The sharp corners and unique flow patterns created by diamond-shaped tubes can potentially increase turbulence and improve fluid mixing, leading to enhanced heat transfer rates.

Also three nanofluid compositions are examined: Alumina/water, MWCNT/water, and a hybrid Alumina-MWCNT/water nanofluid. The simulation results are expected to provide insights into the combined effects of tube geometry and nanofluid type on heat exchanger efficiency.

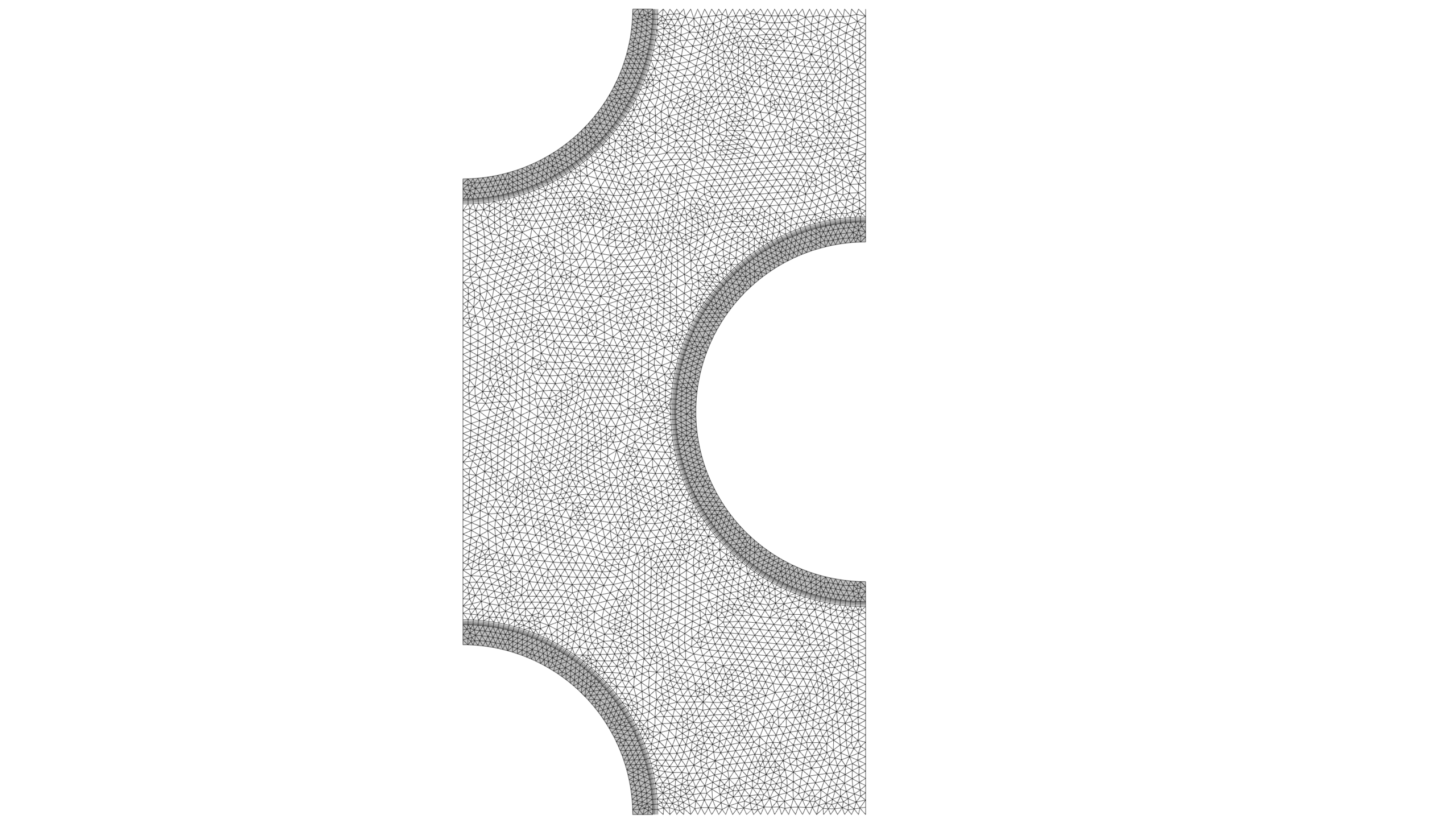

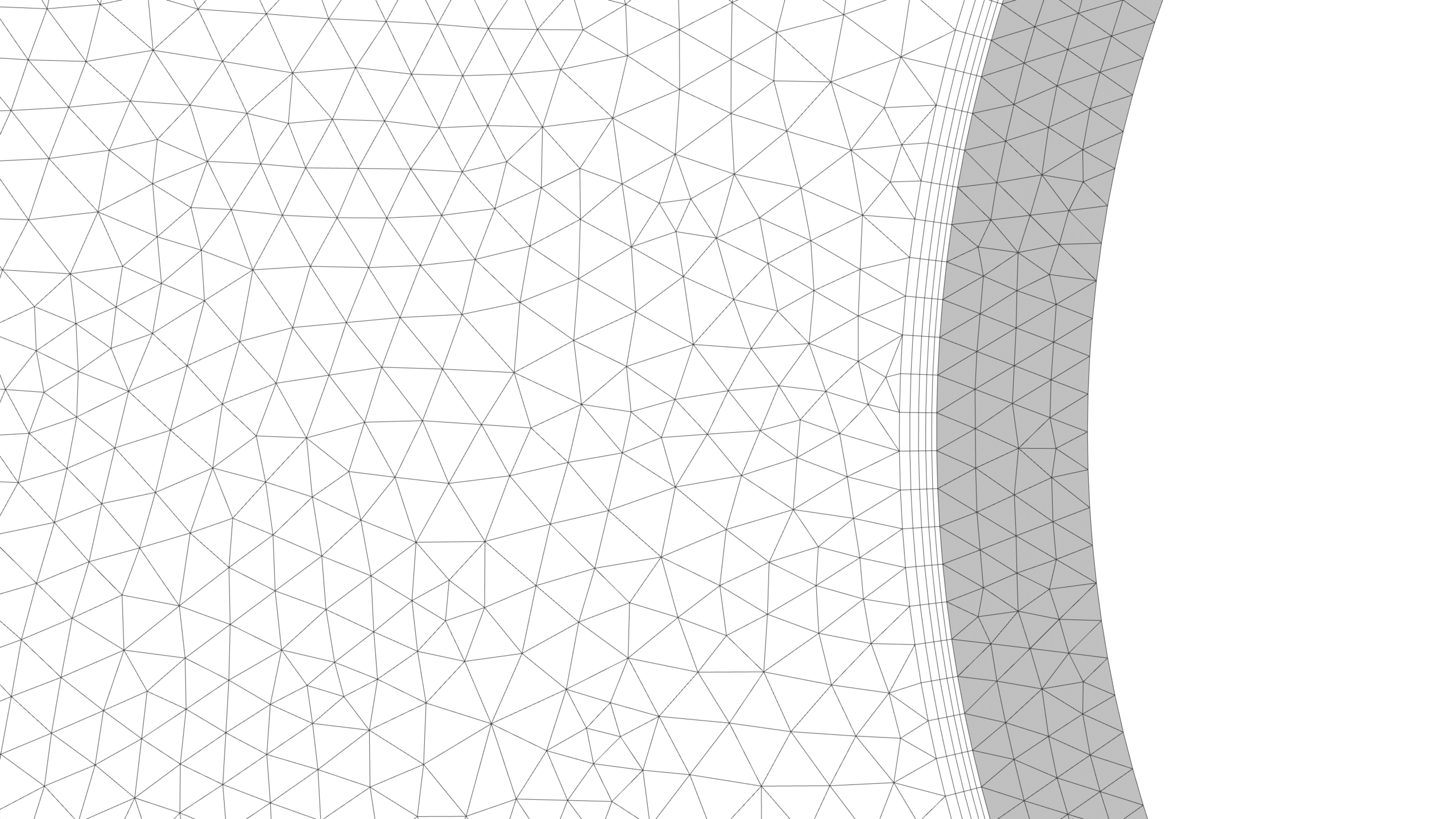

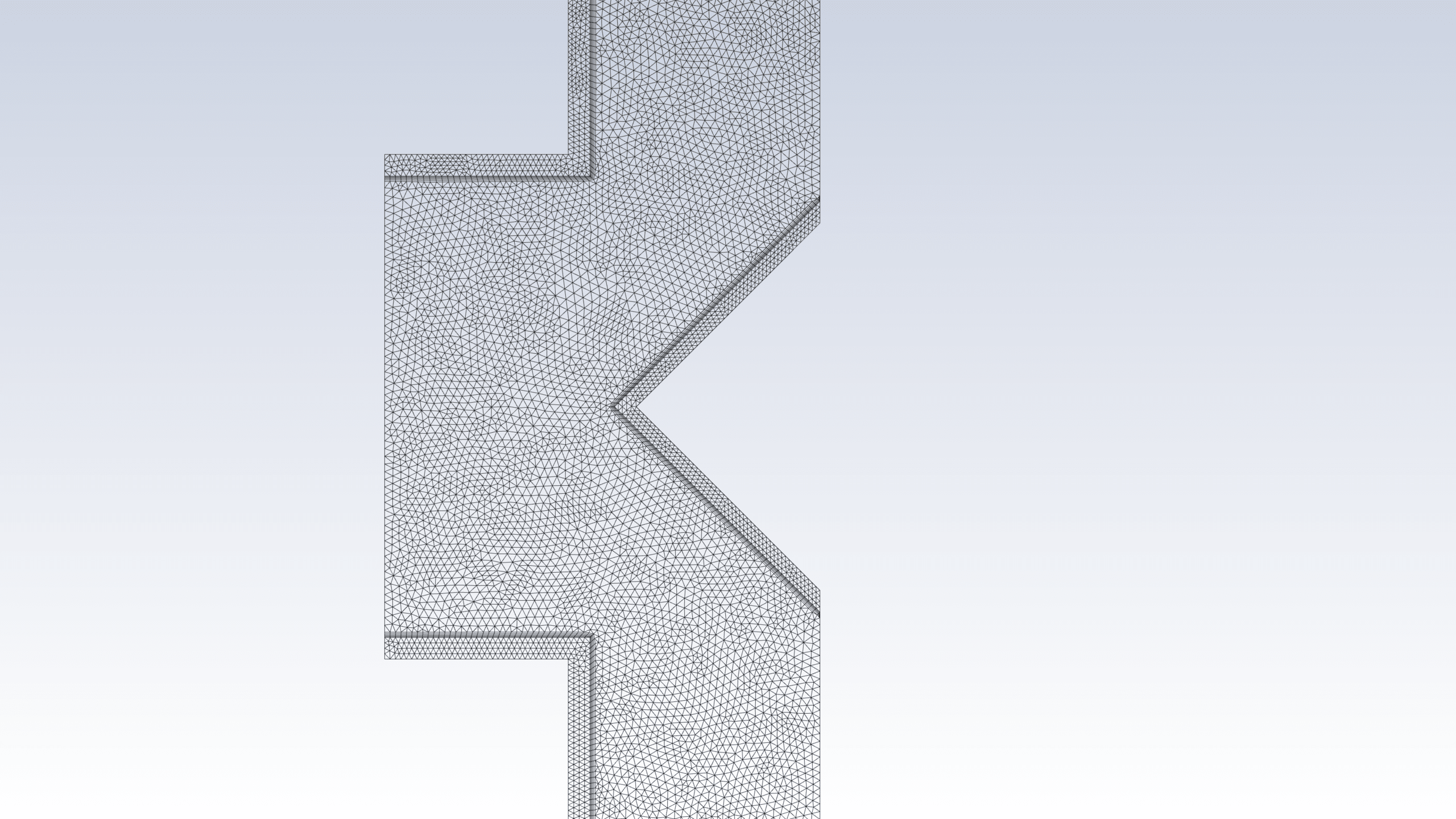

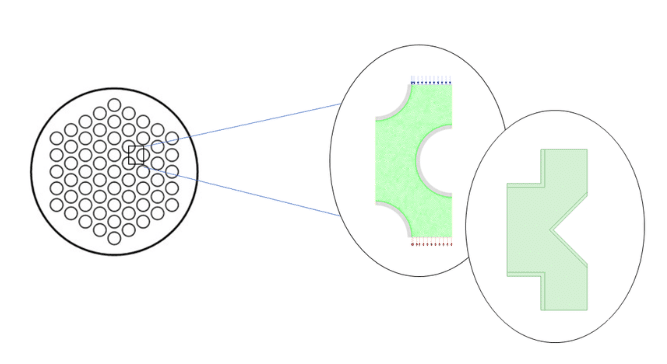

The 2-D geometry of the model is designed in SpaceClaim software in which it includes only a half and two quarters of the tube walls and the fluid flow in the shell zone between them So the fluid inside the tubes is not considered. The inner and outer diameter of the tube are 33.8 and 37.8 [mm] (fig. 1)

Figure 1.

Then we meshed it in ANSYS Meshing producing 11,971 and 12,430 elements for circular and diamond tube respectively.

Methodology

By simulating both circular and diamond-shaped tubes in ANSYS Fluent, we aim to quantify the potential improvements in heat transfer efficiency. This comparative analysis will provide valuable insights into the effectiveness of geometric modifications in optimizing heat exchanger performance, particularly when combined with advanced heat transfer fluids such as nanofluids.

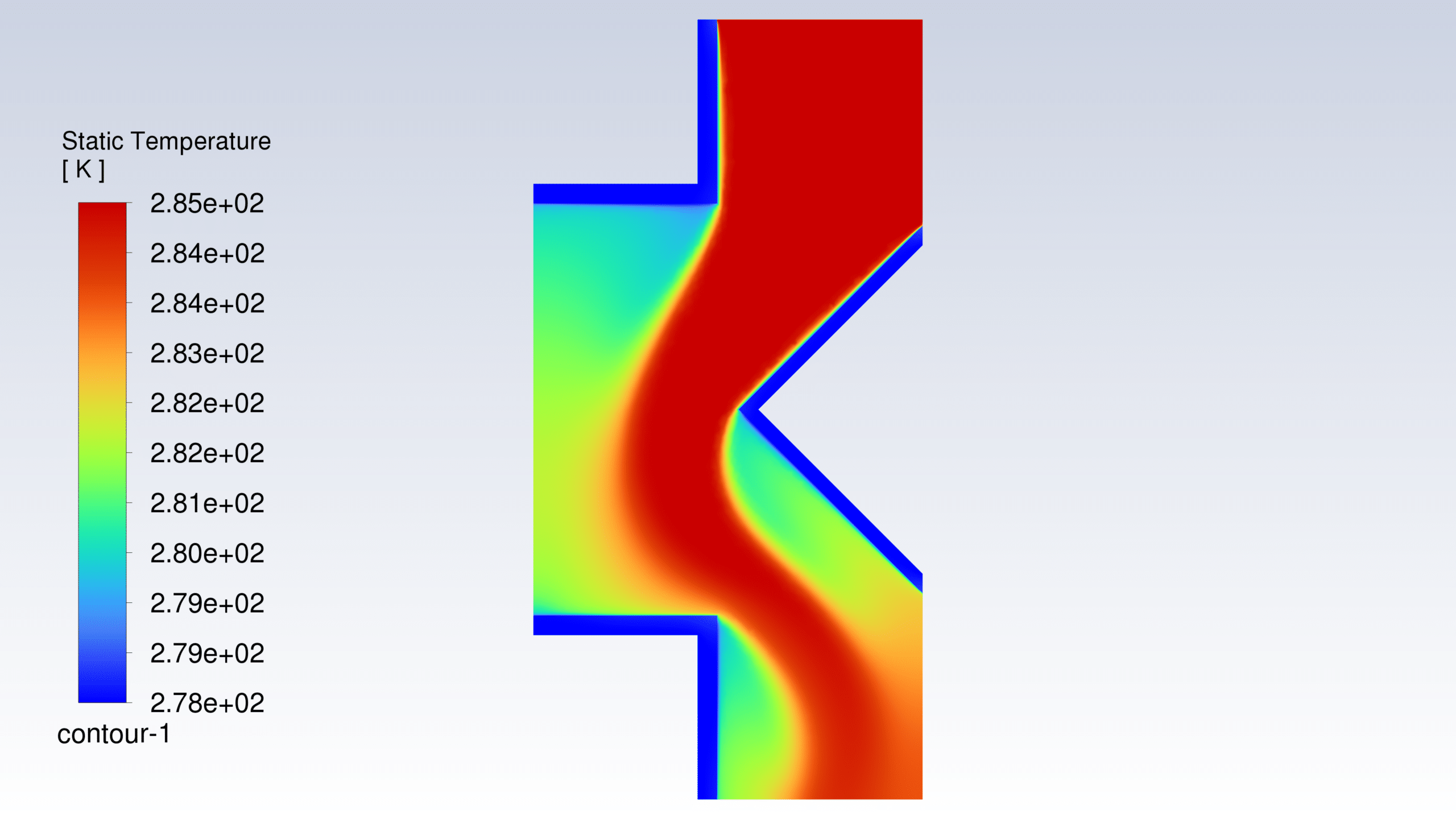

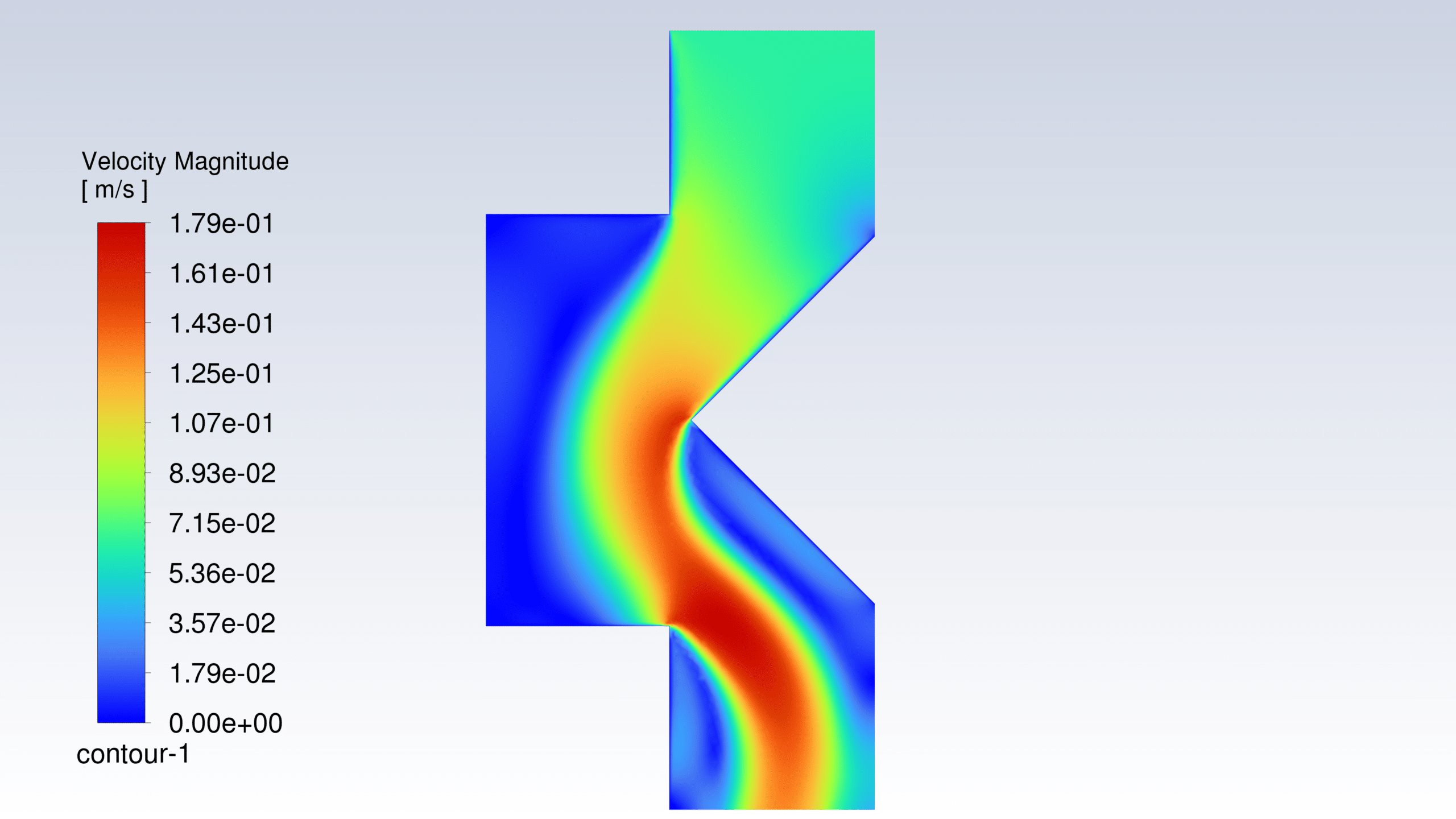

The simulation is done at Reynolds number of 2700 and the turbulence of the flow is simulated by Realizable k-epsilon model. the fluid enters the domain with 285 [k] temperature.

The inner tube walls are set to constant temperature of 278 [k] that are cooler than the entering fluid, so the heat is transferred through the tube thickness (conduction) then via the fluid (convection).

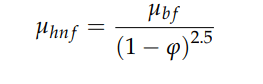

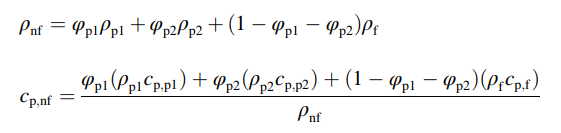

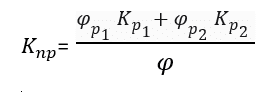

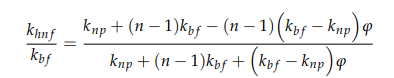

The single phase model is considered to simulate nanoparticle presence in the base fluid. The single-phase model for nanofluids in ANSYS Fluent is a simplified approach to simulating nanofluid behavior. It treats the nanofluid as a homogeneous fluid assuming nanoparticles and base fluid move at the same velocity. This model uses modified thermophysical properties (density, viscosity, thermal conductivity, specific heat) that are calculated based on nanoparticle concentration and base fluid properties. Hybrid nanofluid containing two kinds of nanoparticle is considered for its significant potential of heat transfer enhancement. The nanofluid thermophysical properties are calculated using these formulas:

Results

Nanofluid heat transfer results

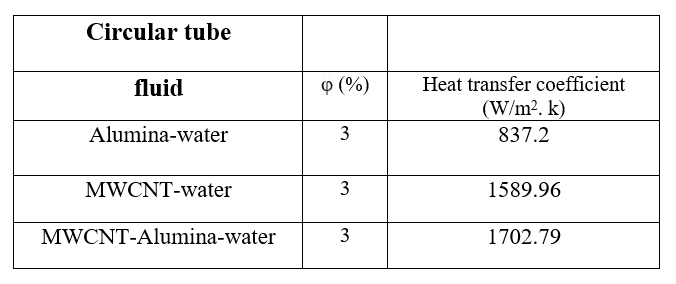

Comparing the results of the heat transfer simulation of the two alumina and MWCNT with 3% nanoparticles at Re=2700 clearly indicates improving heat transfer cause of higher heat transfer coefficient for the MWCNT. Then using hybrid Alumina-MWCNT water increased heat transfer coefficient more than the single MWCNT.

Tube shape effect

Changing the tube shape from circle to diamond has dramatically increased heat transfer rate. The following table contains the result:

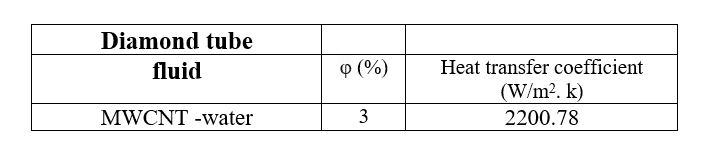

The temperature contours and the animations show how the heat is transferred via conduction through the wall (from the inner surface of the tubes to the shell side) as the fluid flows in the shell.

Reviews

There are no reviews yet.