Turbine Vane Flow With LES and k-Omega SST Turbulence Models

$140.00 $70.00 Student Discount

- This study investigates the aerodynamic performance of a turbine vane using CFD simulations with two different turbulence models

- The simulations were conducted using ANSYS Fluent, comparing the k-Omega SST and Large Eddy Simulation (LES) turbulence models

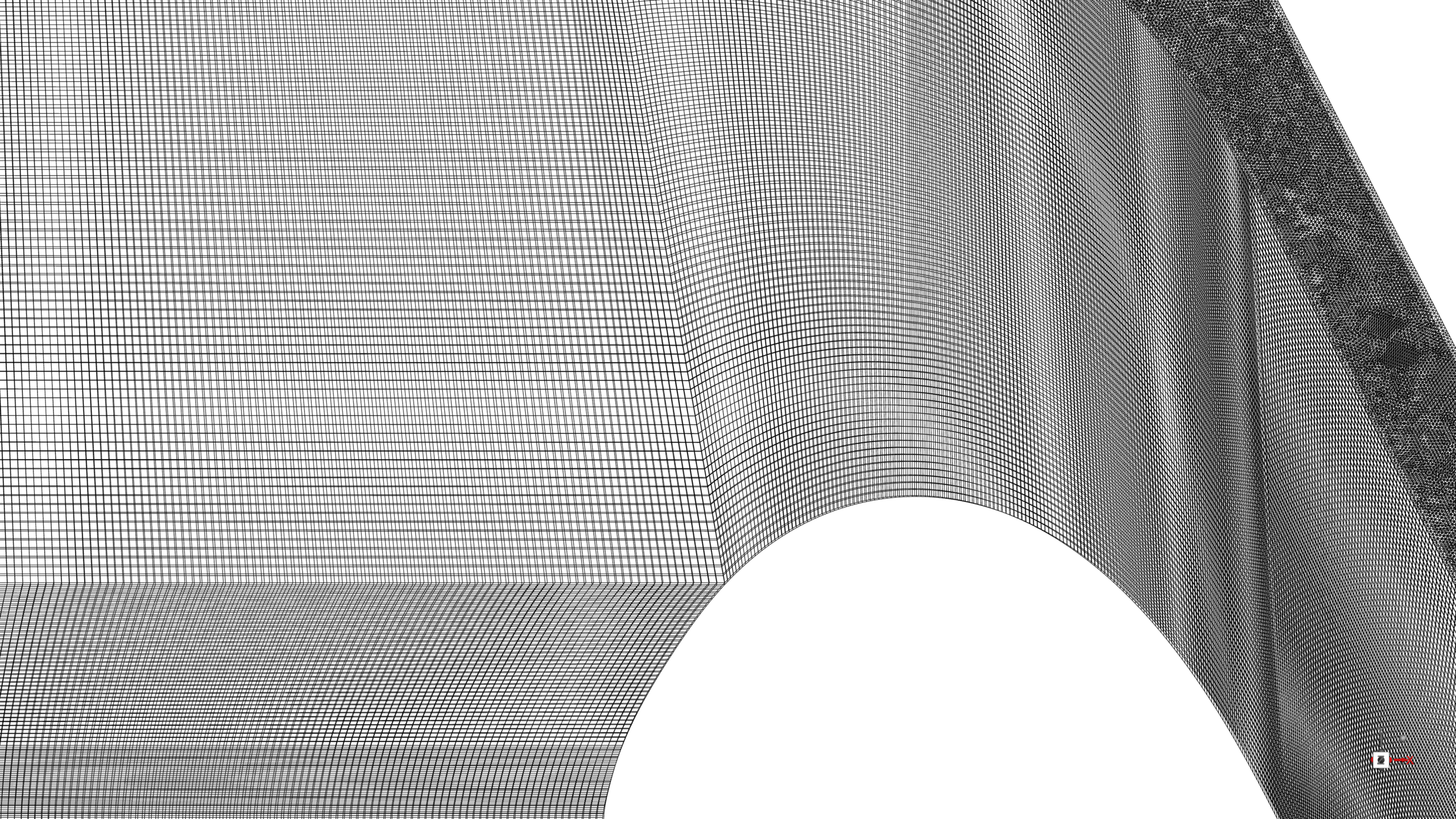

- The geometry of the turbine vane was created using ANSYS Design Modeler. The computational domain was then discretized using ANSYS Meshing, resulting in a high-resolution structured mesh of 12,634,415 elements

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

This study investigates the aerodynamic performance of a turbine vane using Computational Fluid Dynamics (CFD) simulations with two different turbulence models. The simulations were conducted using ANSYS Fluent, comparing the k-Omega SST and Large Eddy Simulation (LES) turbulence models. The study aims to analyze the flow characteristics and turbulence effects within the turbine vane passage, providing insights into the relative strengths and differences between these two popular turbulence modeling approaches.

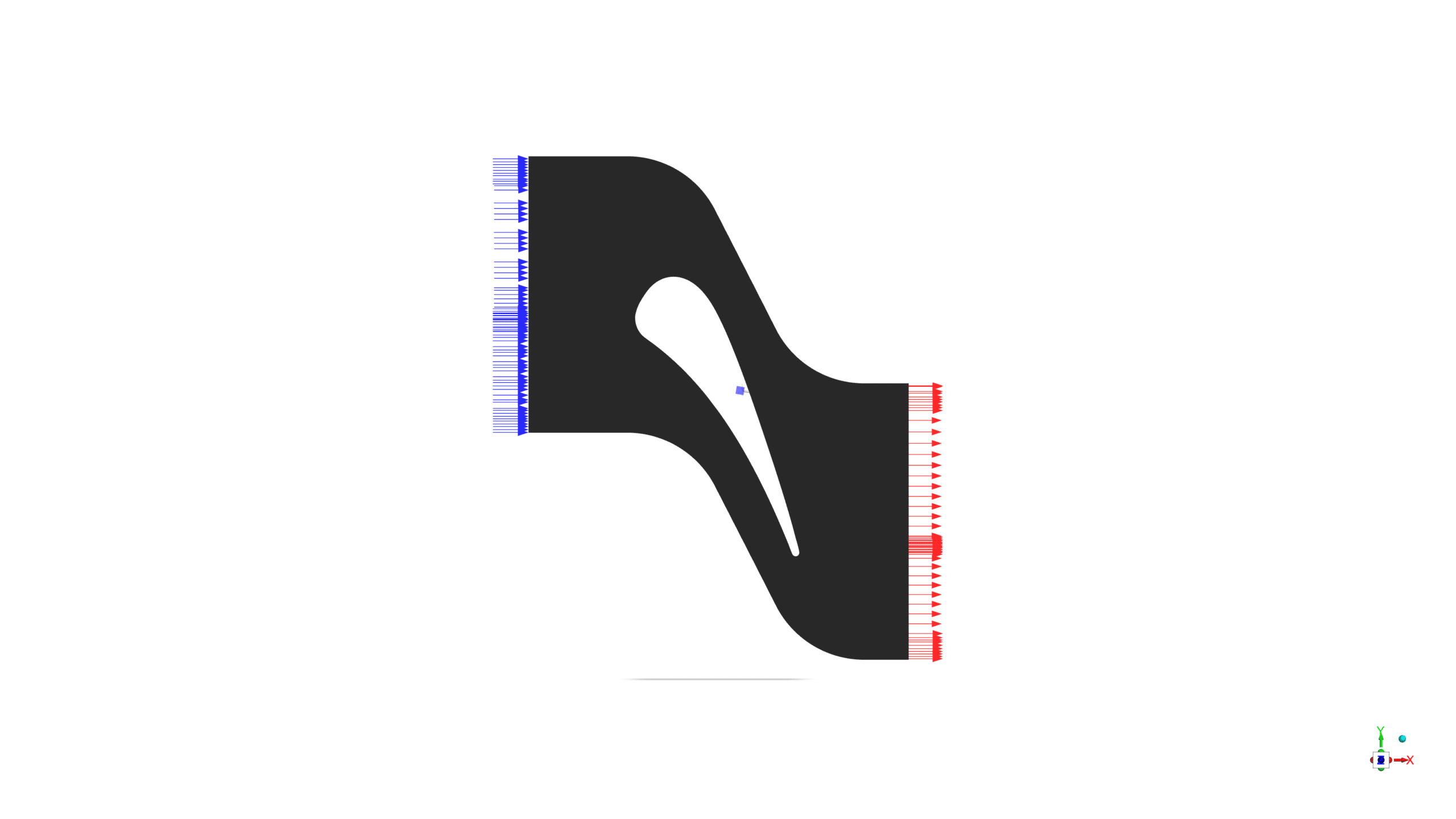

The geometry of the turbine vane was created using ANSYS Design Modeler. The computational domain was then discretized using ANSYS Meshing, resulting in a high-resolution structured mesh of 12,634,415 elements, ensuring accurate capture of the complex flow features around the vane.

Methodology

The simulation of Turbine Vane setup included a pressure-based solver in steady-state conditions. The energy equation was enabled to account for compressibility effects. Air was modeled as an incompressible ideal gas, entering from the left boundary and exiting through the right vertical boundary.

Two separate simulations were performed using identical geometry and mesh, but with different turbulence models:

- k-Omega SST (Shear Stress Transport) model

- Large Eddy Simulation (LES) model

These models were chosen to compare a widely-used RANS (Reynolds-Averaged Navier-Stokes) approach (k-Omega SST) with a more computationally intensive but potentially more accurate scale-resolving method (LES).

Results

The CFD simulations using the k-Omega SST and LES turbulence models provided detailed insights into the aerodynamic performance of the turbine vane. The results are summarized as follows:

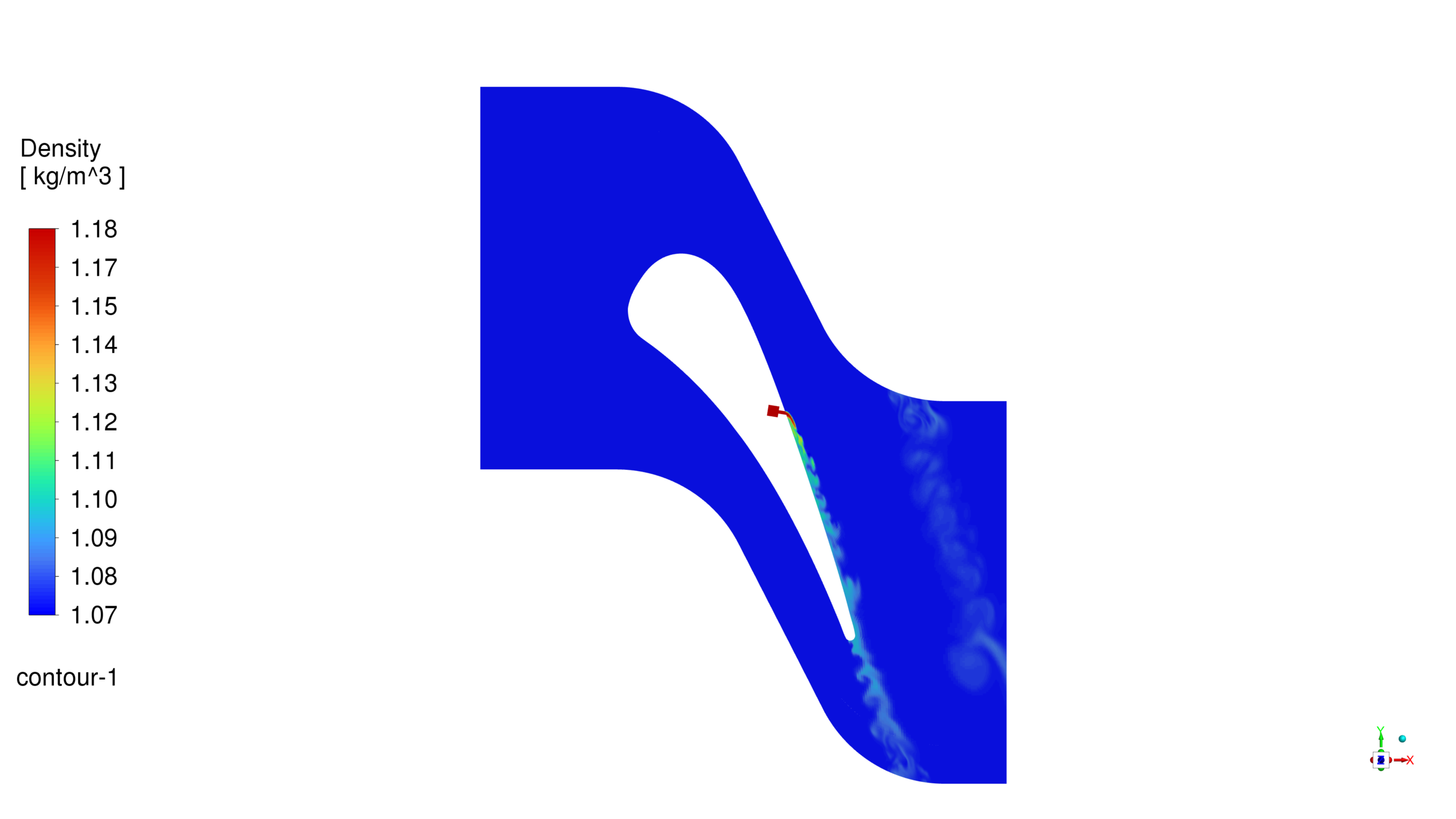

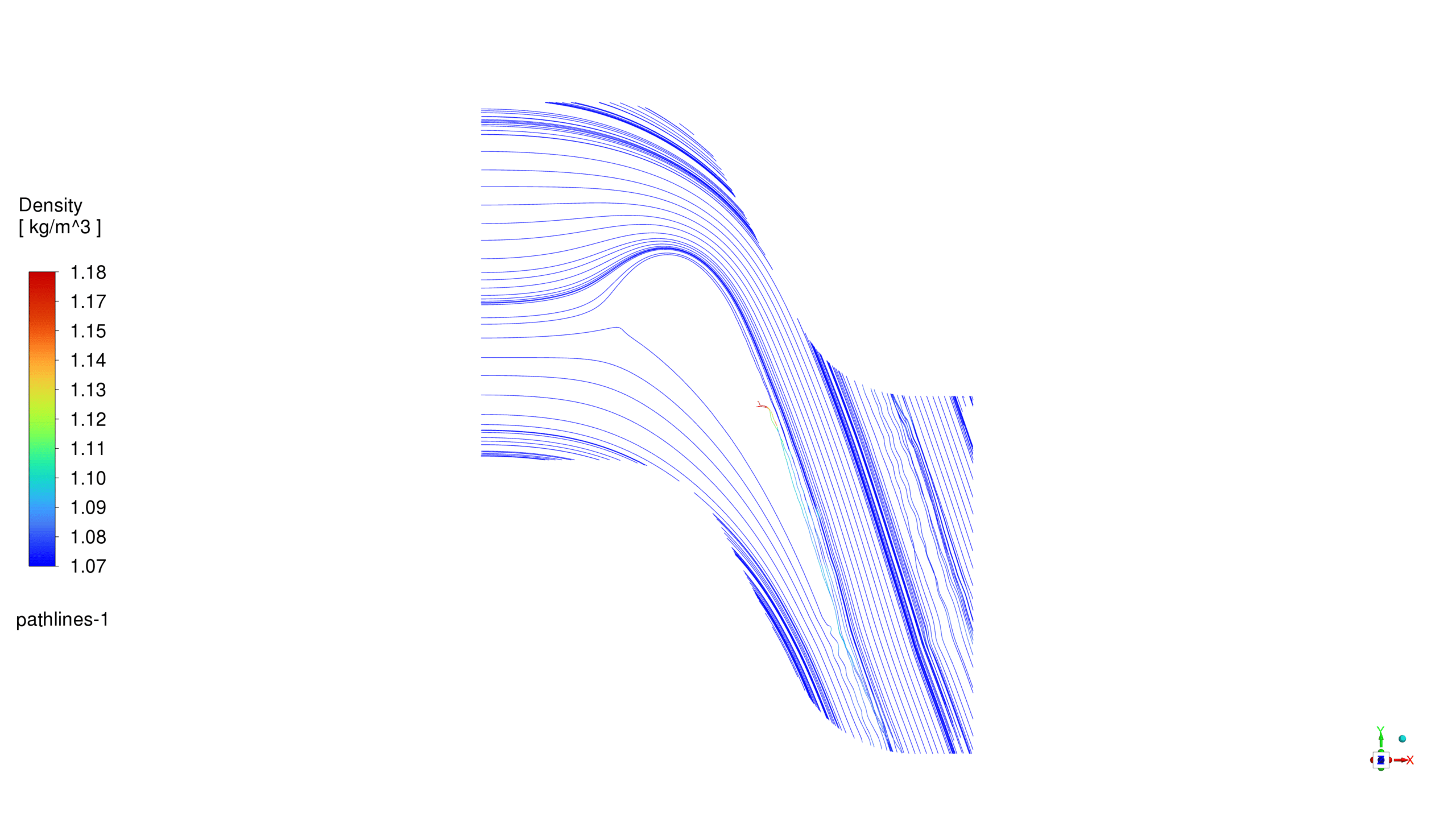

Density Distribution

The density contours indicate a variation in density across the vane passage. The highest density regions are observed at the leading edge, where compression effects are significant. The k-Omega SST model shows slightly smoother density gradients compared to the LES model, which captures more detailed fluctuations, particularly in the wake region.

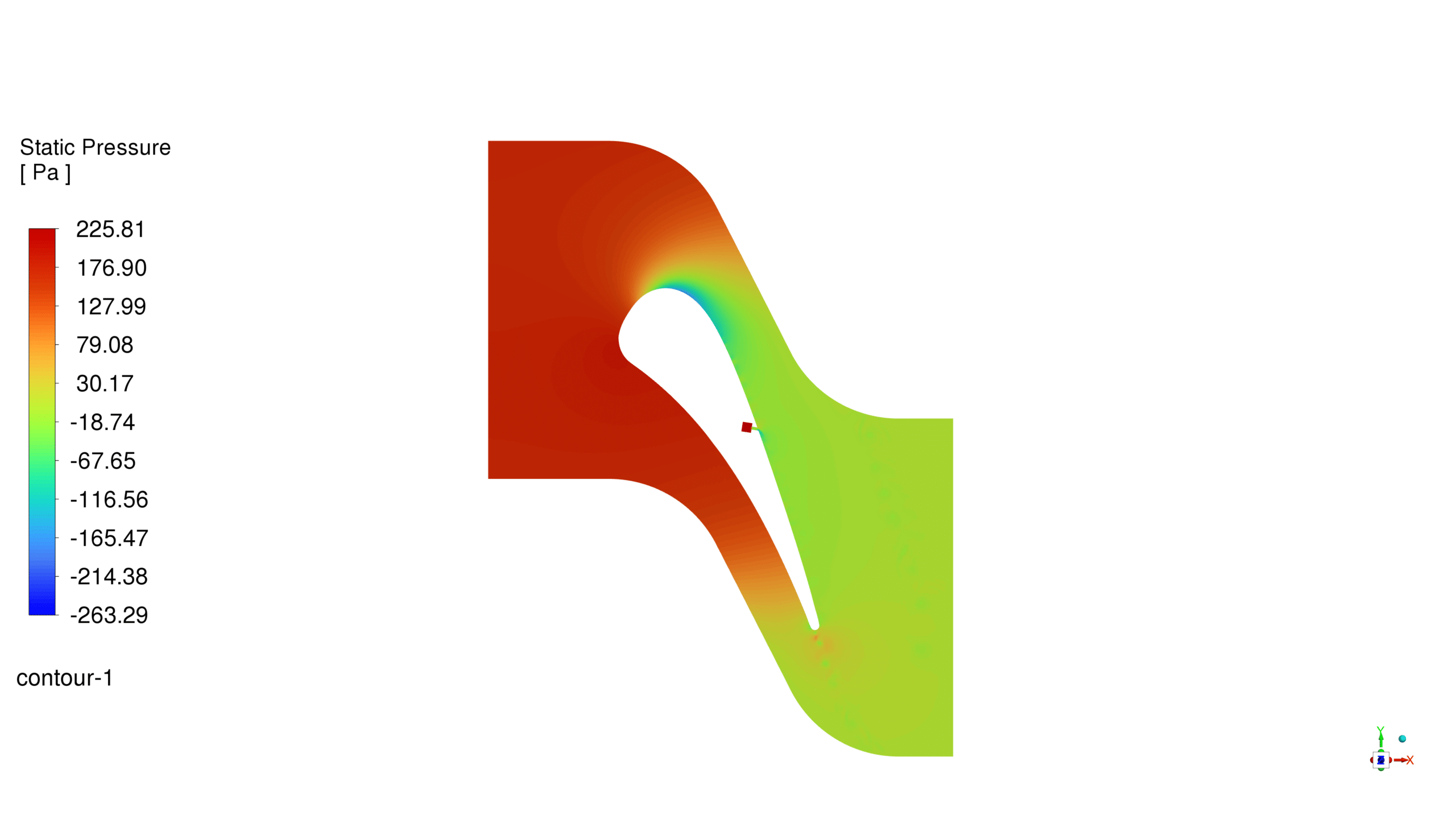

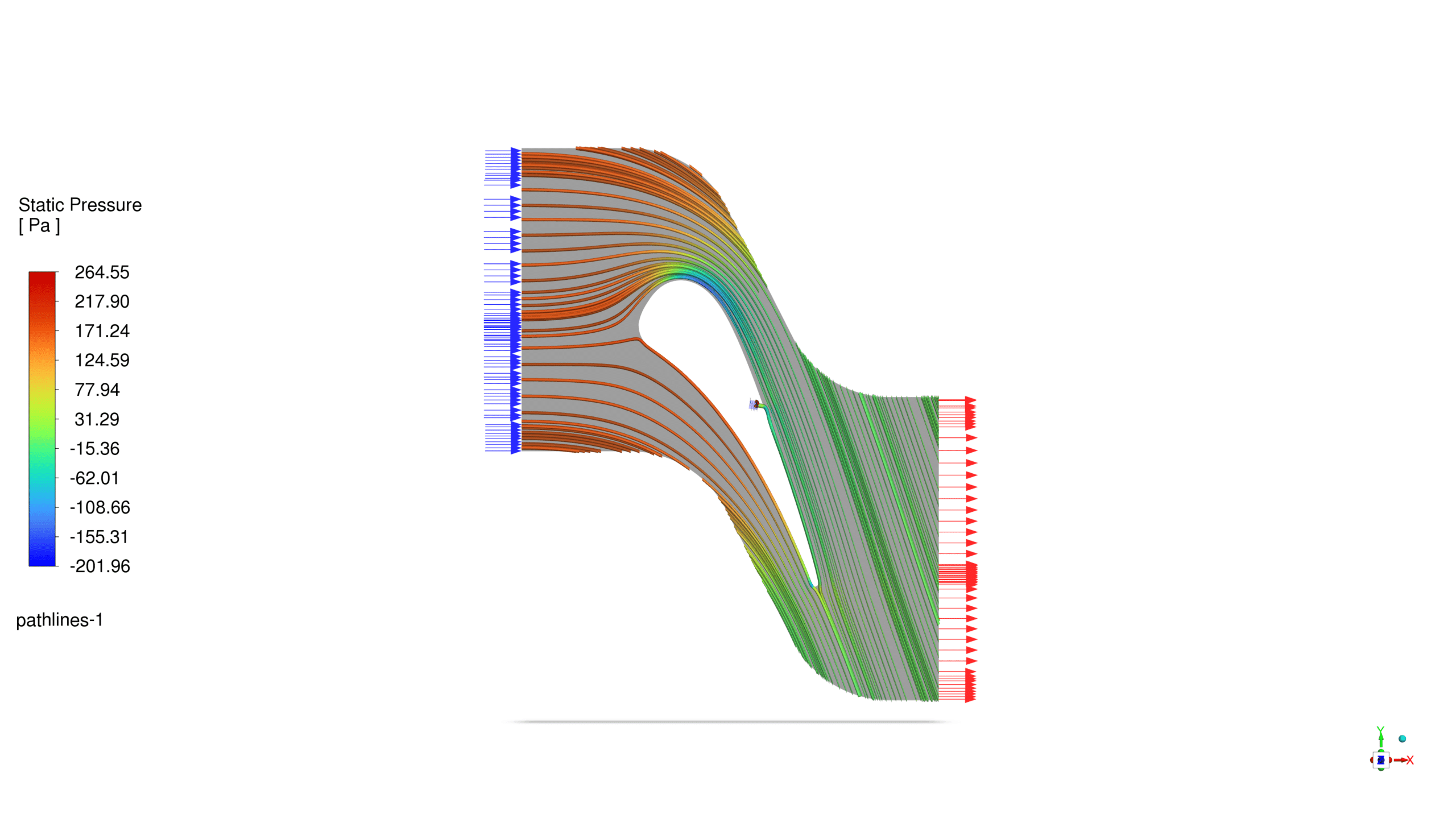

Static Pressure Distribution

The static pressure contours reveal high-pressure regions at the leading edge and low-pressure regions at the trailing edge of the vane. The LES model demonstrates a more pronounced pressure drop across the vane, capturing finer details of the pressure distribution, especially in the wake, compared to the k-Omega SST model.

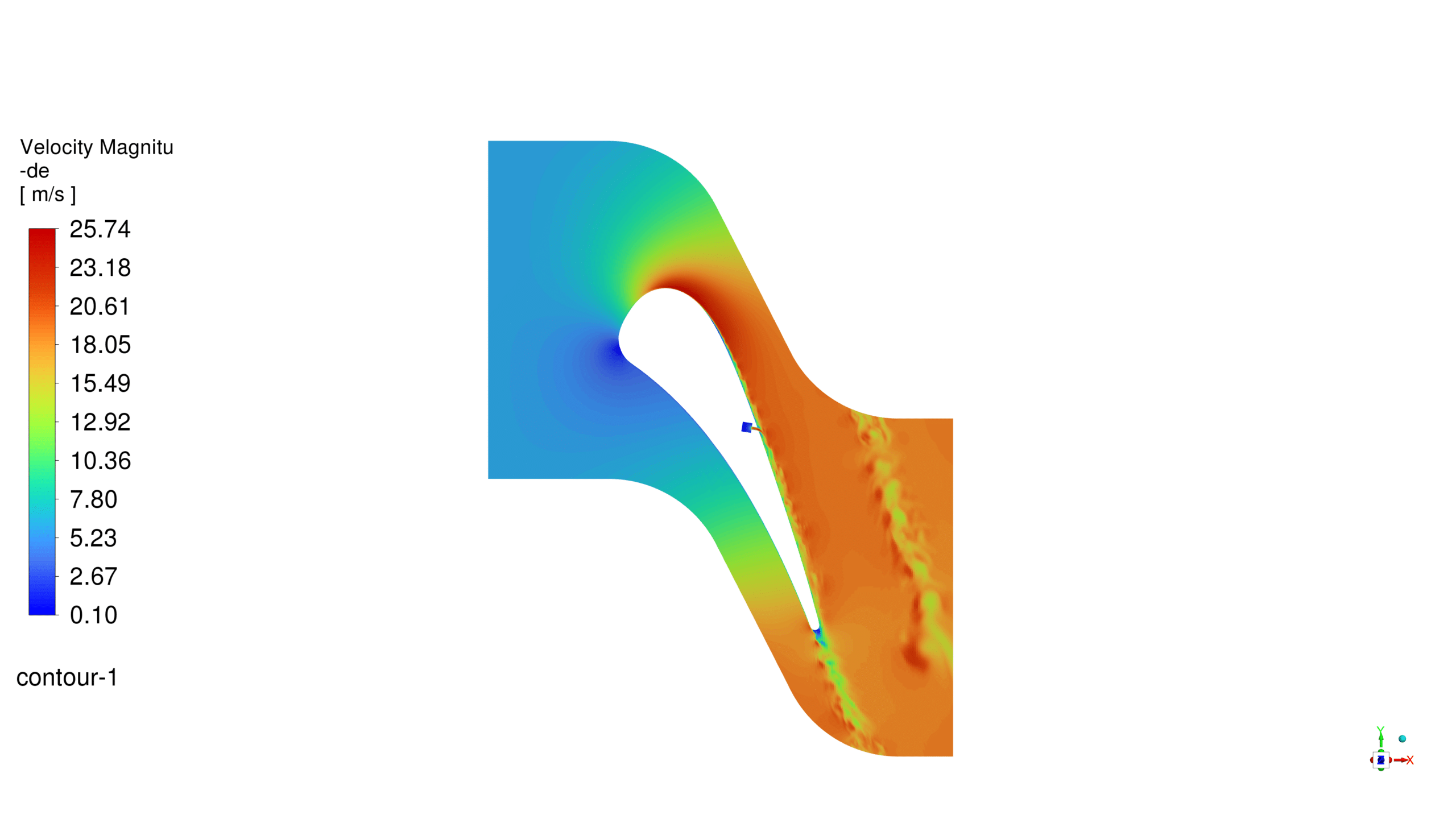

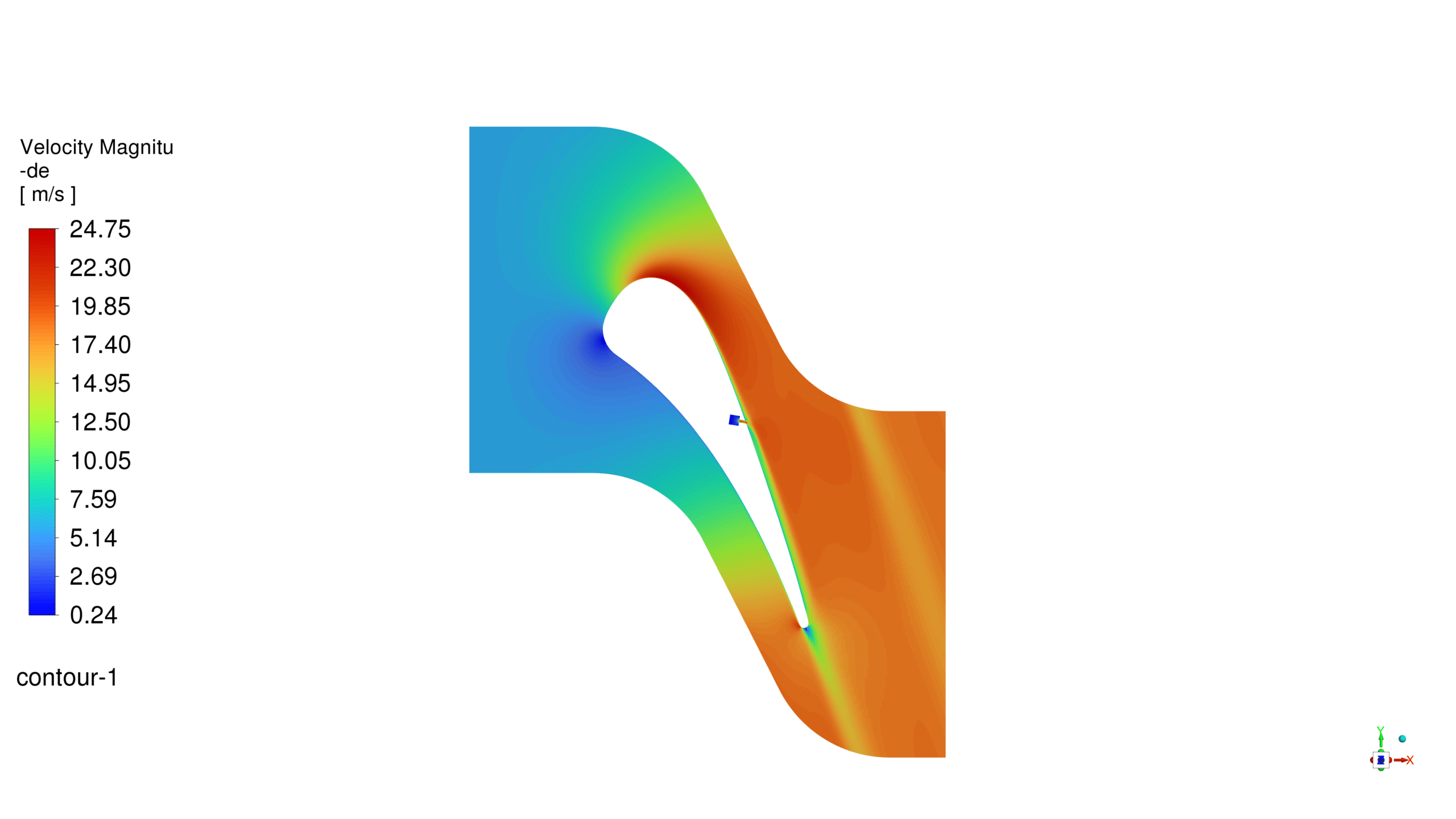

Velocity Magnitude

Velocity contours show acceleration of flow around the vane, with maximum velocities occurring near the trailing edge. The LES model captures higher velocity gradients and more complex flow structures, suggesting better resolution of turbulent eddies compared to the k-Omega SST model.

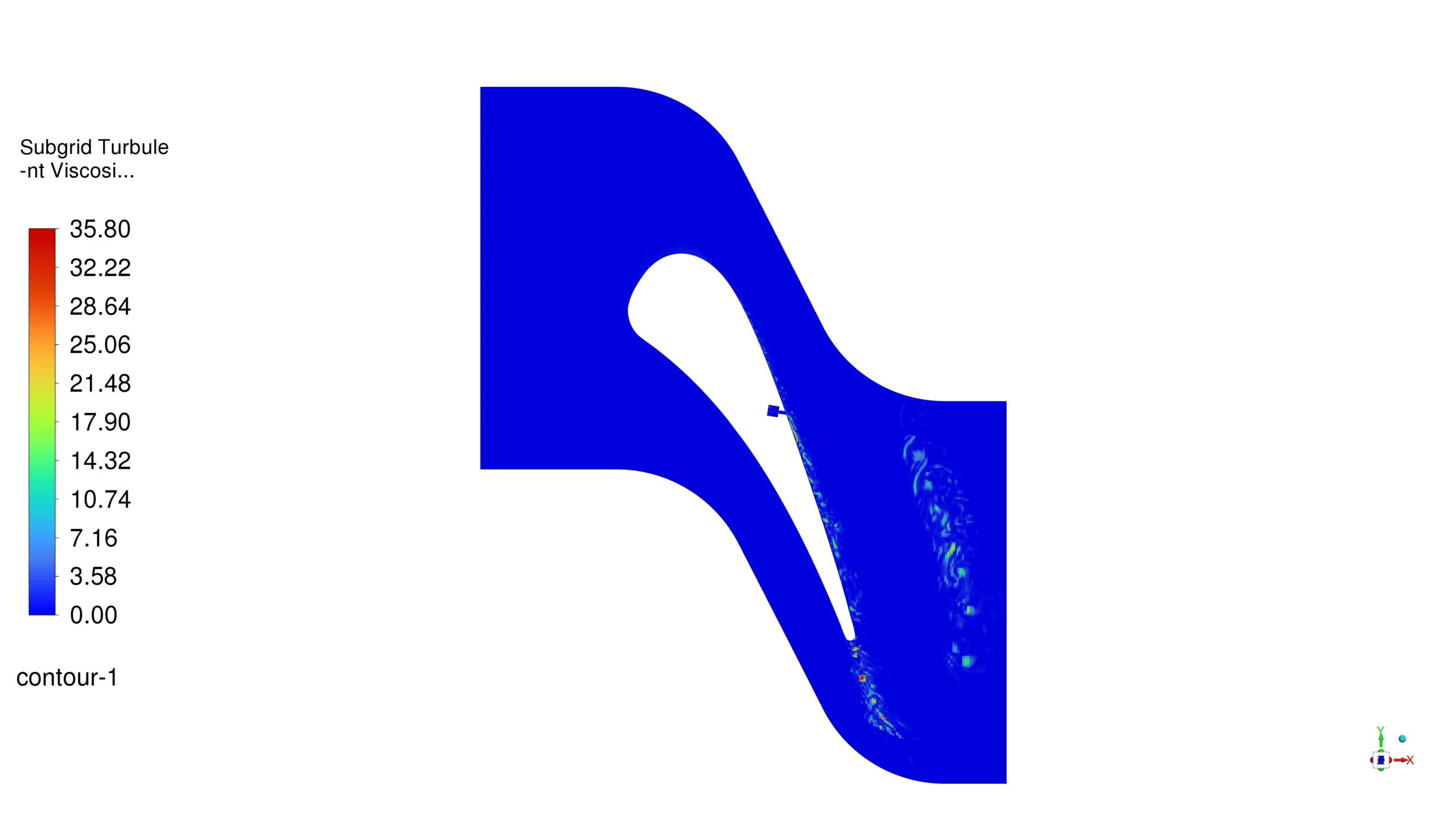

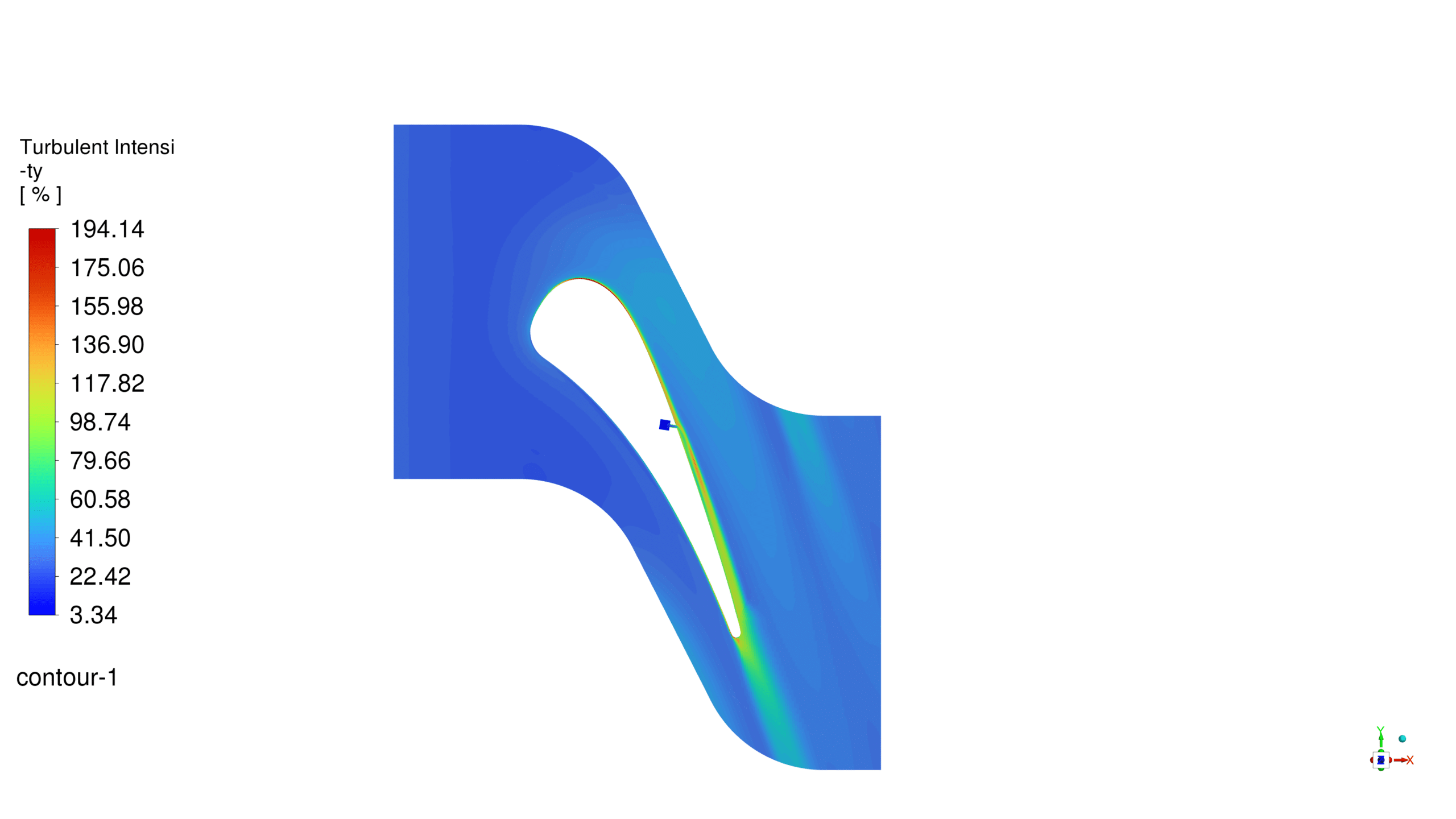

Turbulent Intensity

The turbulent intensity contours highlight regions of high turbulence, particularly downstream of the vane. The LES model predicts higher turbulent intensity levels, indicating its capability to resolve smaller scale turbulence structures, while the k-Omega SST model provides a more averaged view.

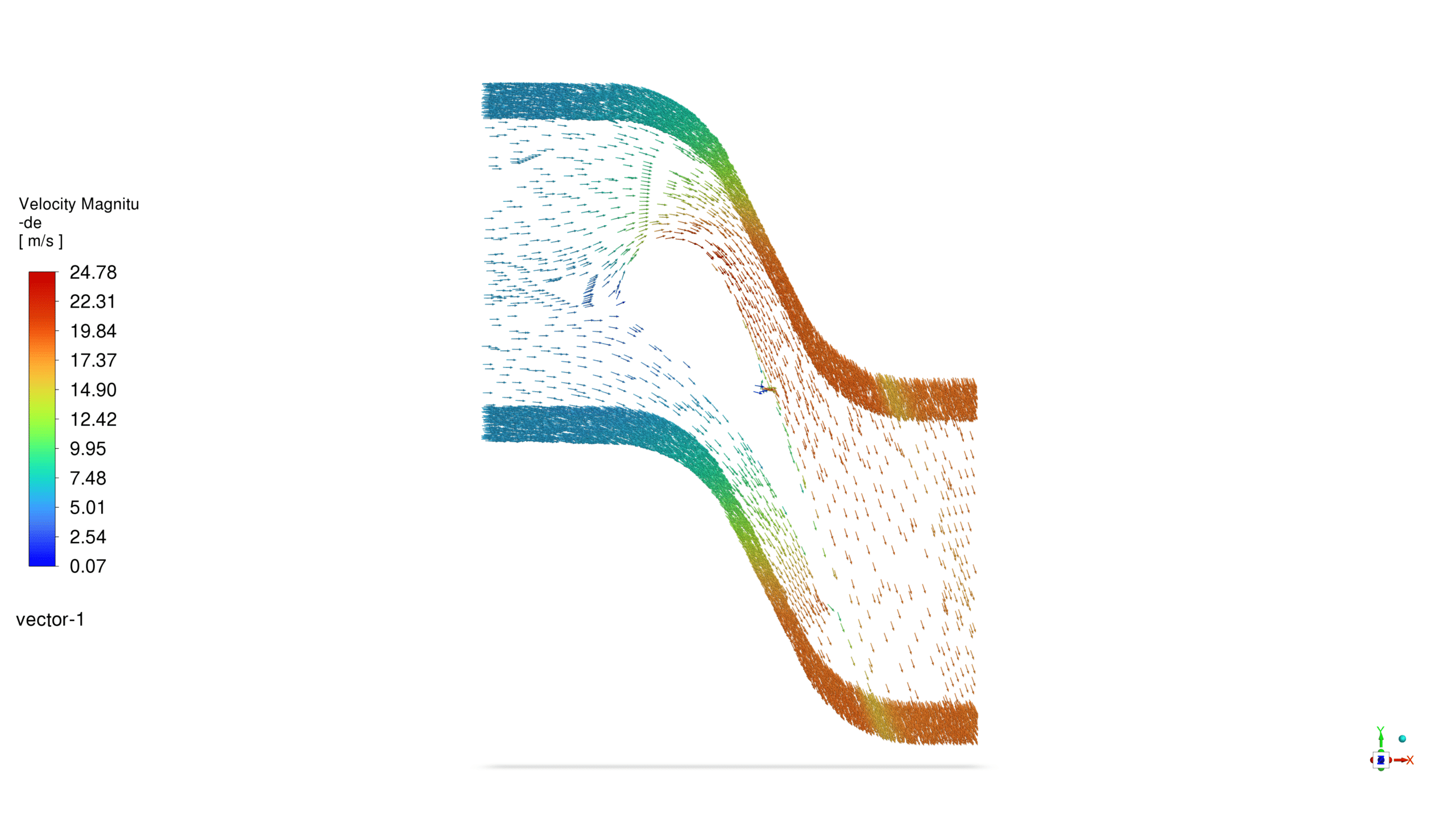

Streamlines and Vector Fields

Streamlines and velocity vectors illustrate the flow path and direction through the vane passage. The LES model shows more intricate flow patterns and vortex formations, providing a detailed visualization of the flow dynamics, whereas the k-Omega SST model presents a more streamlined flow with less complexity.

Overall, the LES model offers a more detailed and accurate representation of the flow characteristics and turbulence effects within the turbine vane passage. However, this comes at the cost of higher computational resources compared to the k-Omega SST model, which provides a good balance between accuracy and computational efficiency.

Reviews

There are no reviews yet.