Twisted Tape Inserts and Vortex Generators in Heat Exchanger CFD Simulation

$120.00 $60.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Twisted Tape Inserts and Vortex Generators in Heat Exchanger CFD Simulation, ANSYS Fluent

Introduction

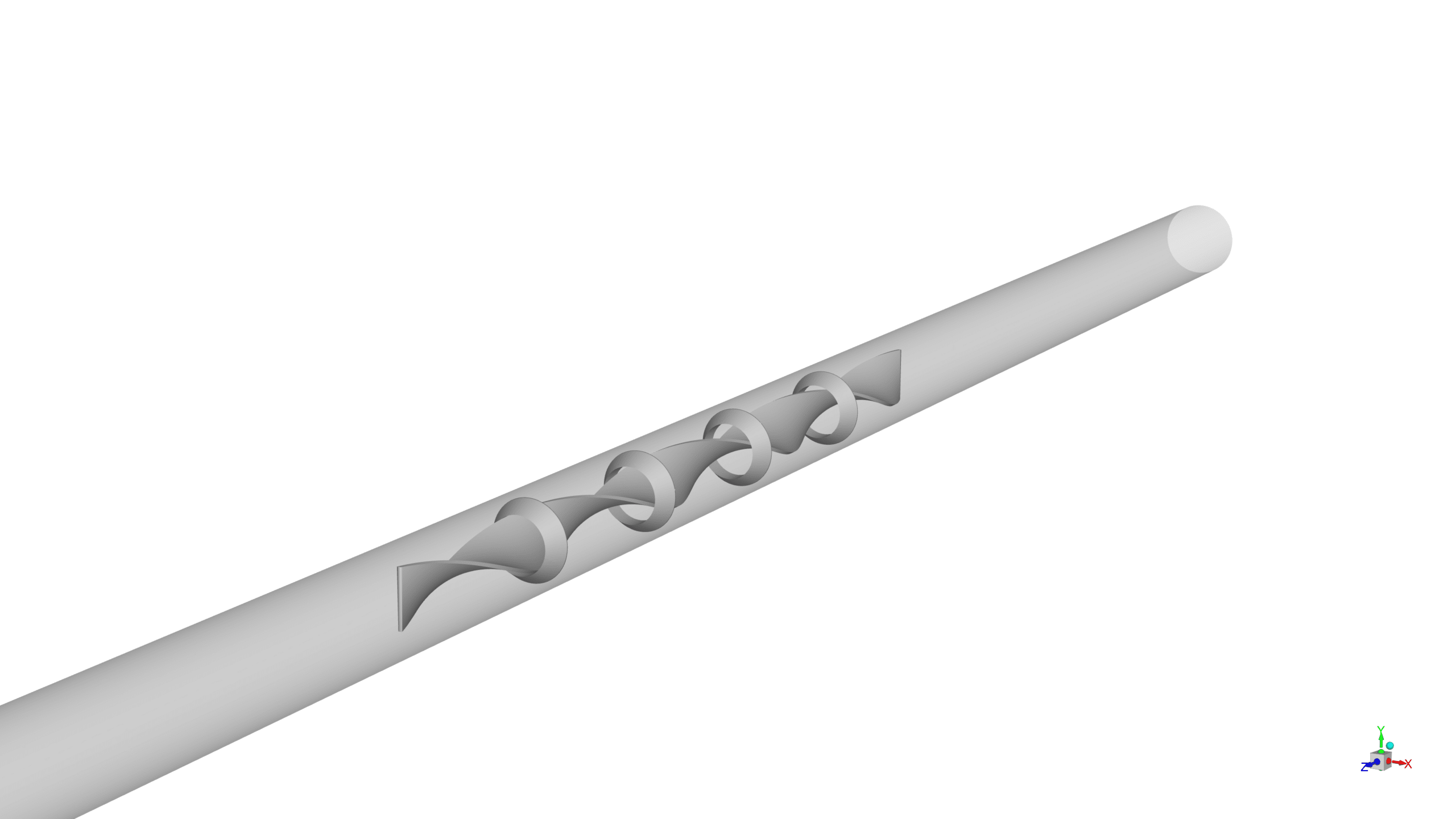

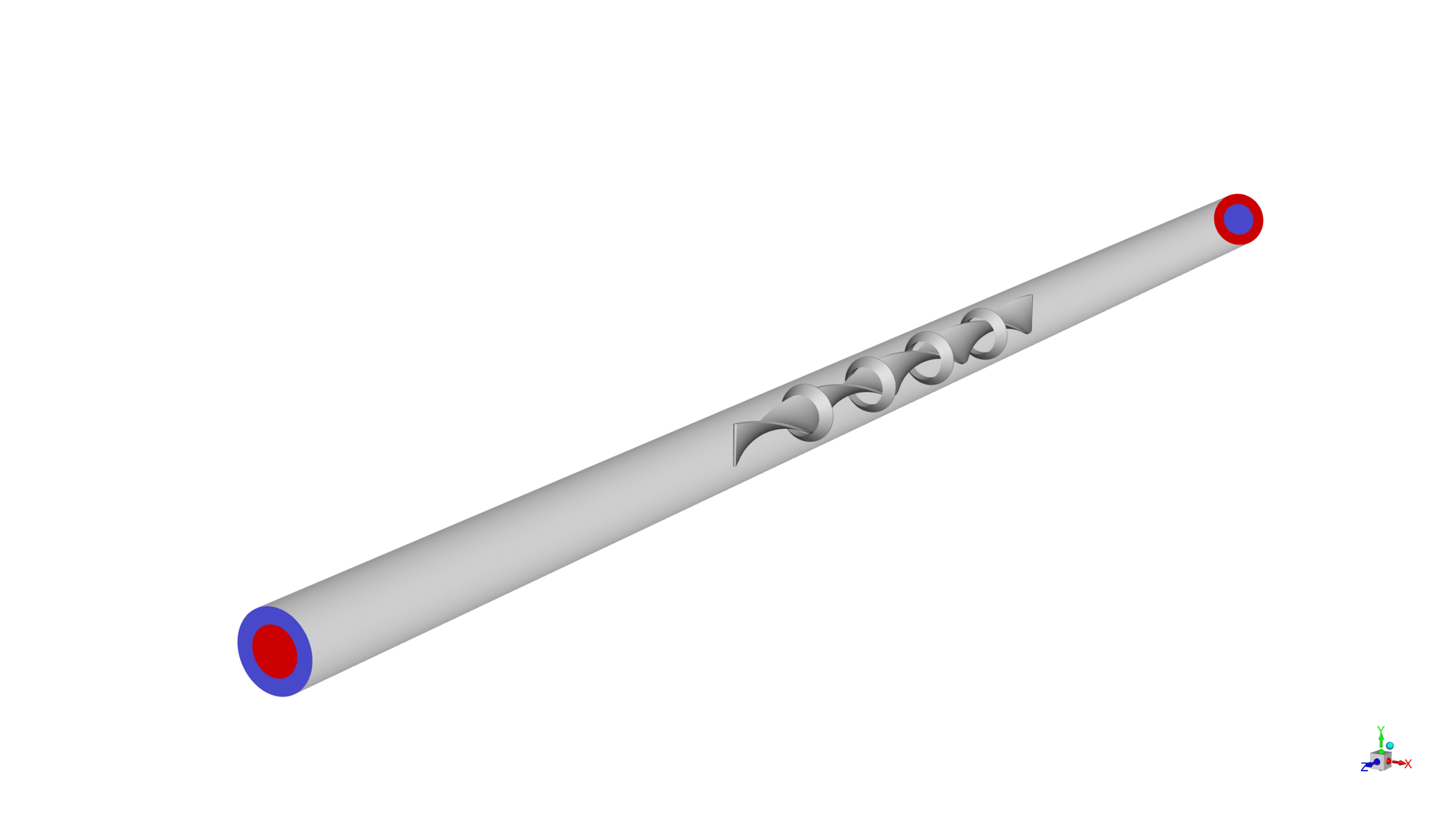

Heat transfer enhancement in tubular heat exchangers is crucial for improving thermal efficiency in various industrial applications. This study explores the thermal and fluid dynamic performance of a tube with twisted tape inserts and vortex generators using Computational Fluid Dynamics (CFD) analysis. The tube features two sections: an inner section where hot alumina nanofluid flows and an outer section with ambient airflow.

The primary objective of this research is to analyze the effects of twisted tape inserts and vortex generators on the flow patterns, heat transfer characteristics, and pressure drop within the tube. By simulating the flow of hot alumina nanofluid through the inner tube while exposed to cooler air flow in the outer section, we aim to understand the cooling process and its impact on the overall heat transfer efficiency.

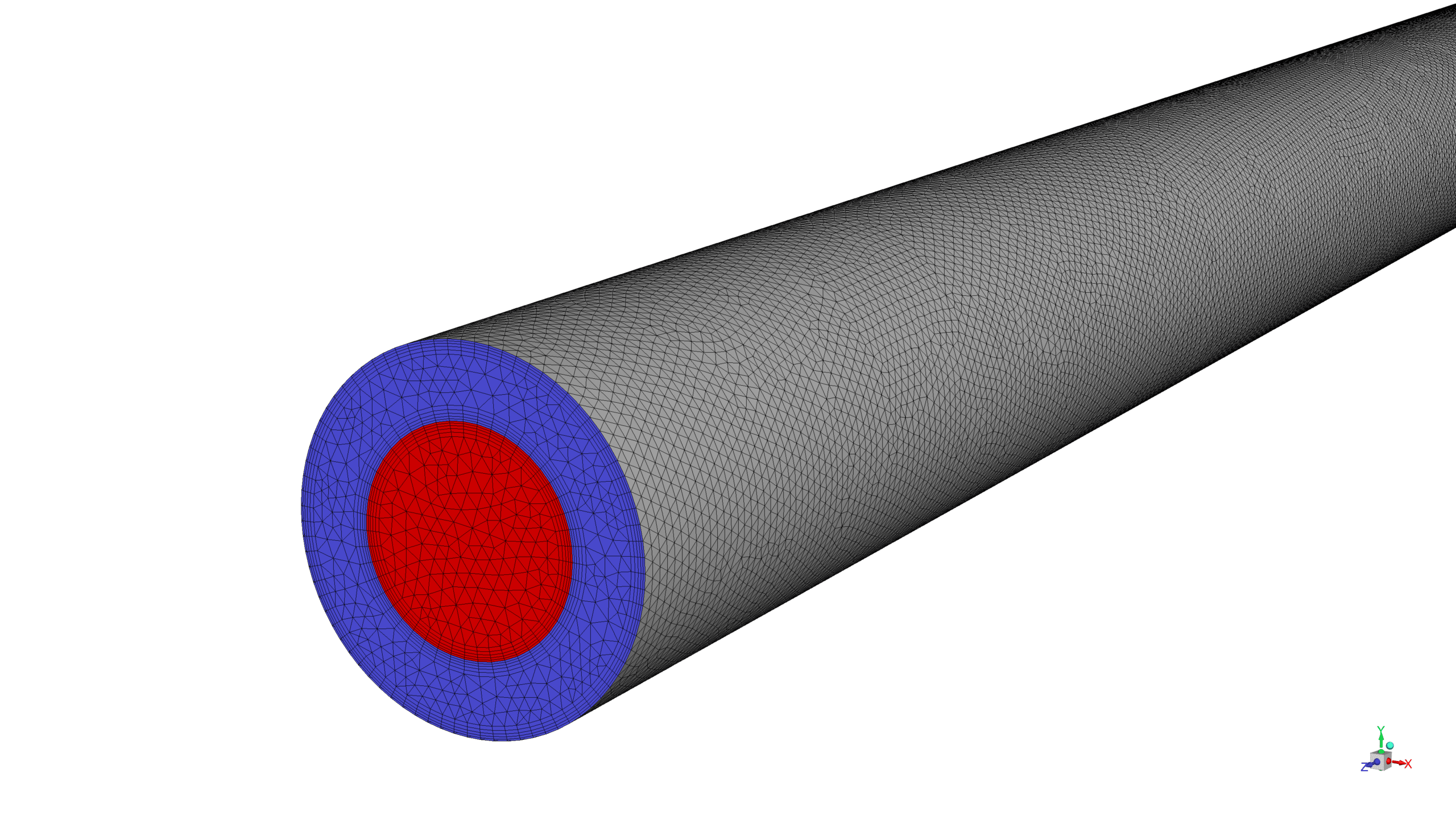

The CFD simulations were conducted using ANSYS Fluent software. The geometry was designed using the ANSYS Design Modeler and meshed using ANSYS Meshing software, while the total number of elements is 4427809.

Methodology

The simulation employs a pressure-based solver suitable for incompressible flows typically encountered in heat exchanger applications.

A steady-state solution approach was adopted to simulate the continuous operation of the heat exchanger under constant flow conditions.

The RNG k-ε turbulence model was used to account for the complex flow patterns within the tube.

The energy equation was enabled to track the temperature distribution and heat transfer within the system.

Results

The CFD simulations reveal significant insights into the thermal and fluid dynamic behavior of the tube with twisted tape inserts and vortex generators:

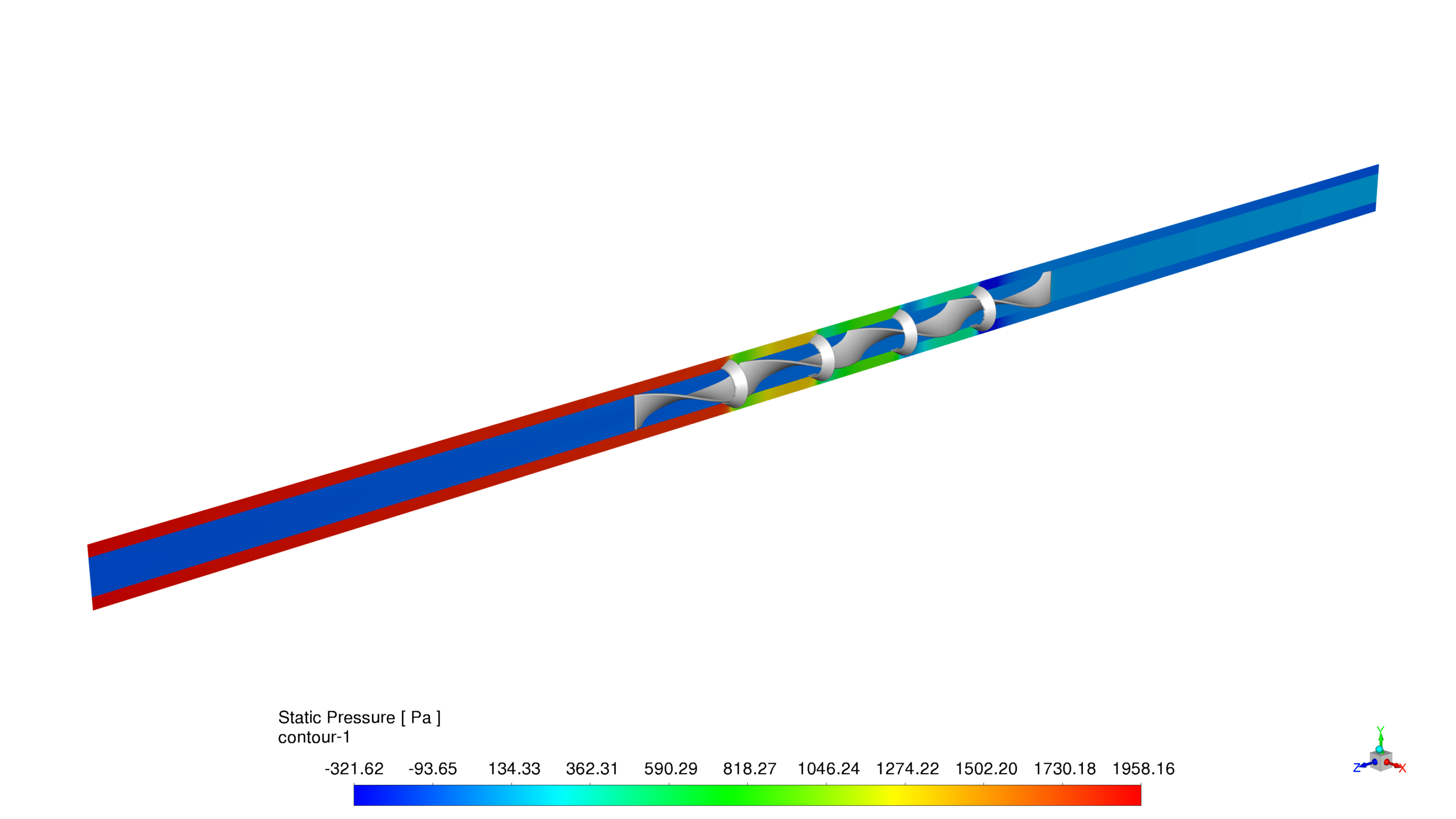

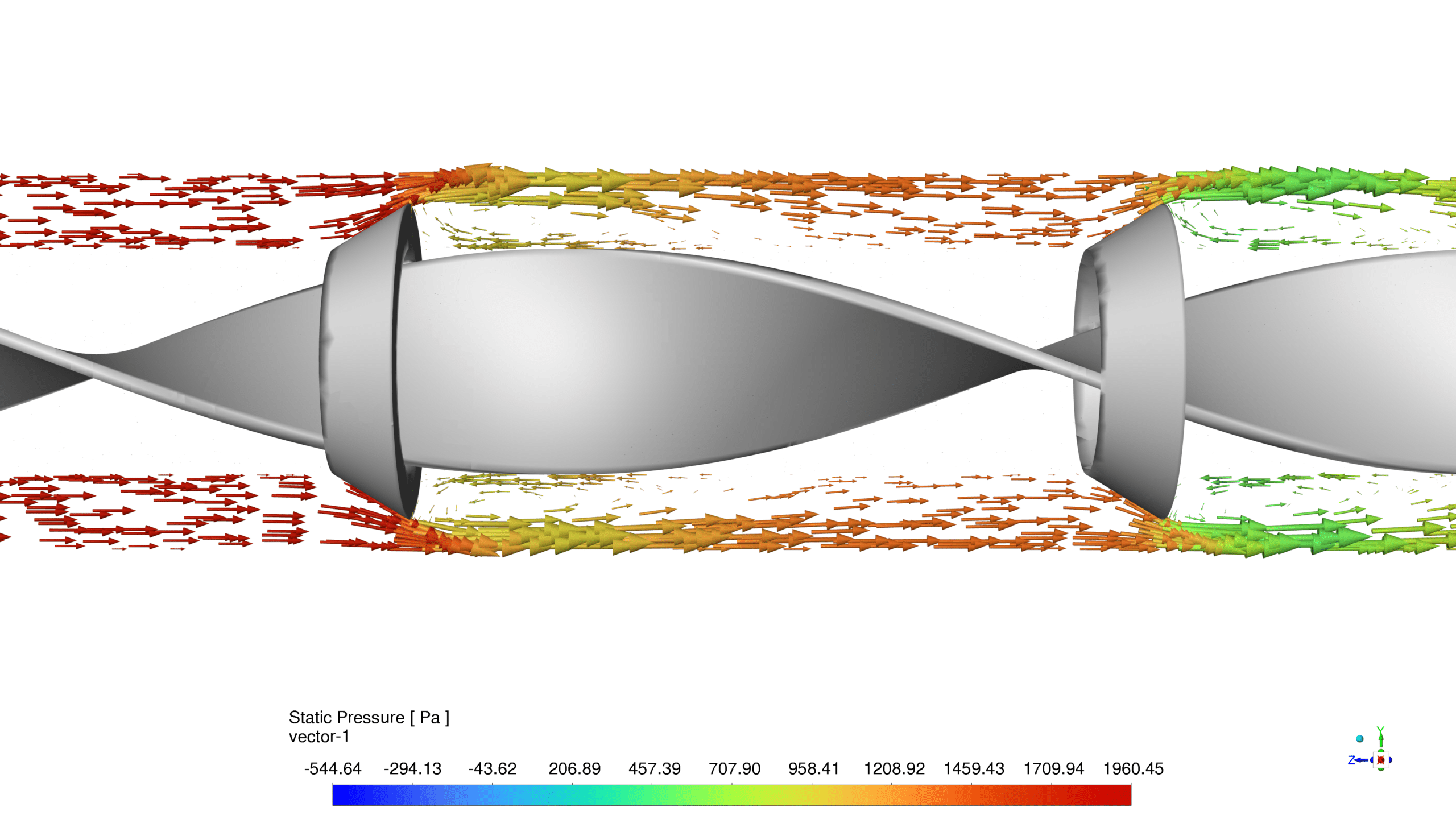

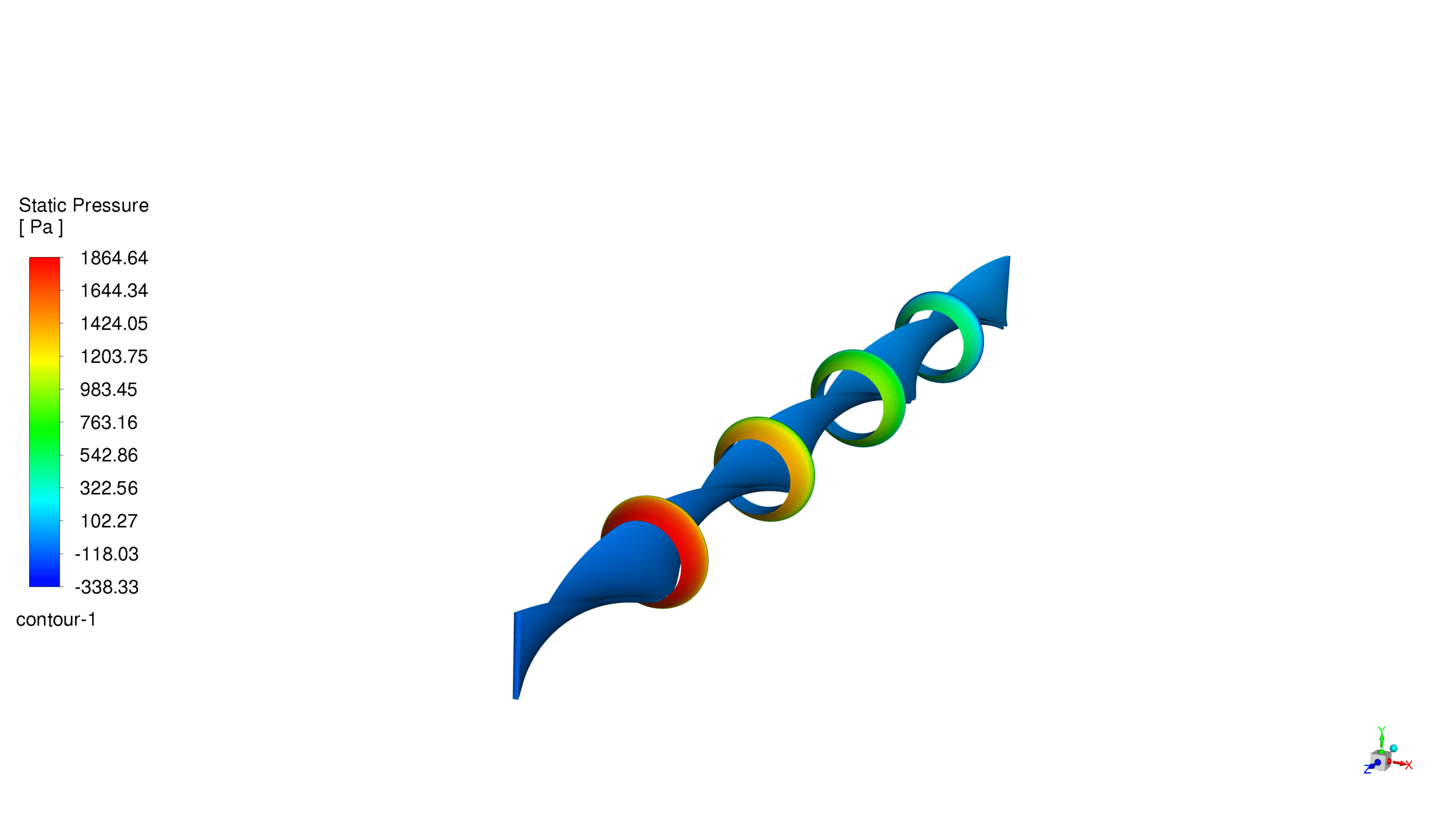

The pressure contours indicate areas of high pressure near the vortex generators and low pressure in the core flow. The pressure drop across the tube ranges from -544.64 Pa to 1960.45 Pa. The area-weighted average static pressure at the gas inlet is 1953.92 Pa and at the nanofluid inlet is 206.98 Pa, while both outlets are at 0 Pa (atmospheric pressure).

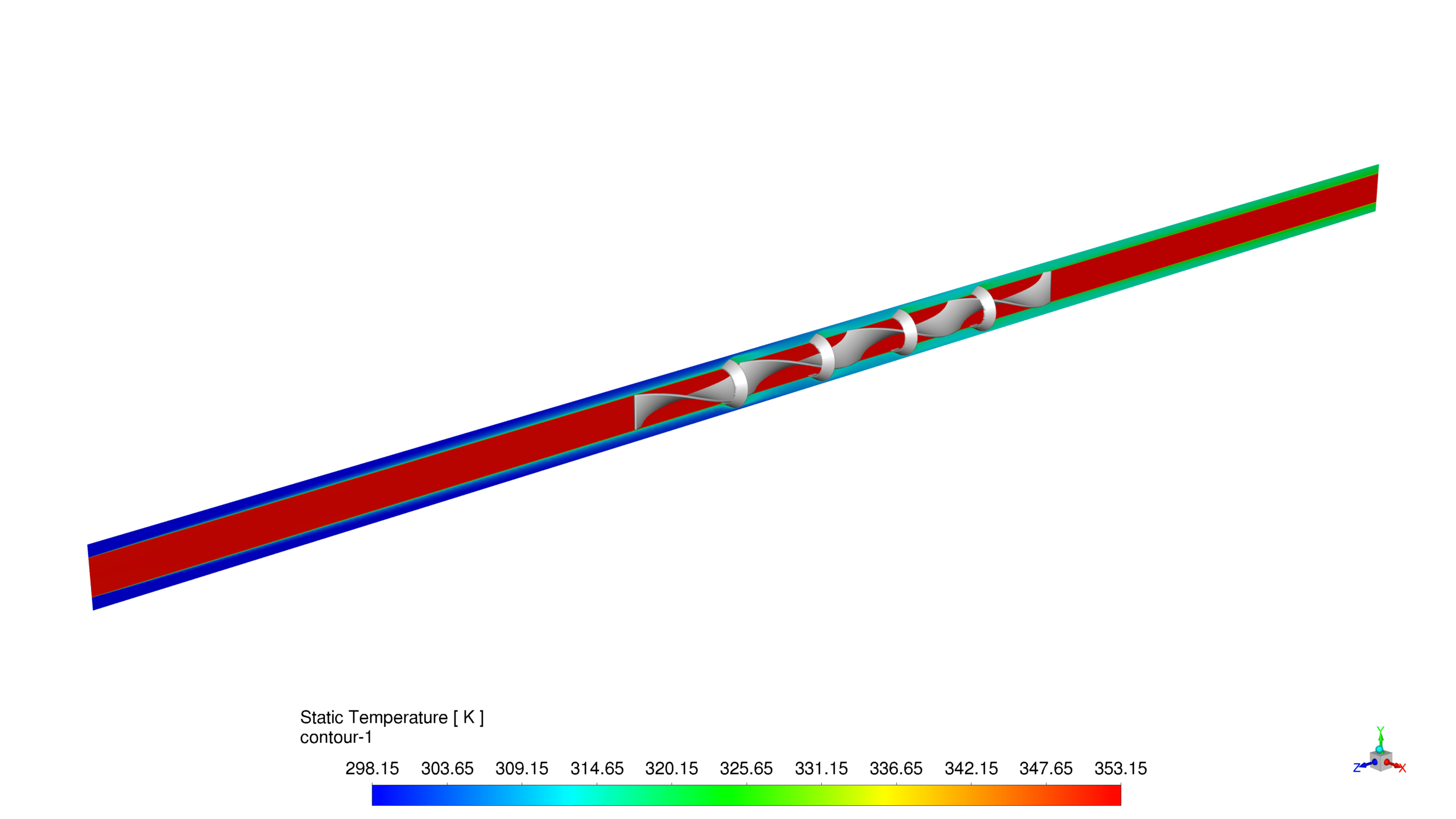

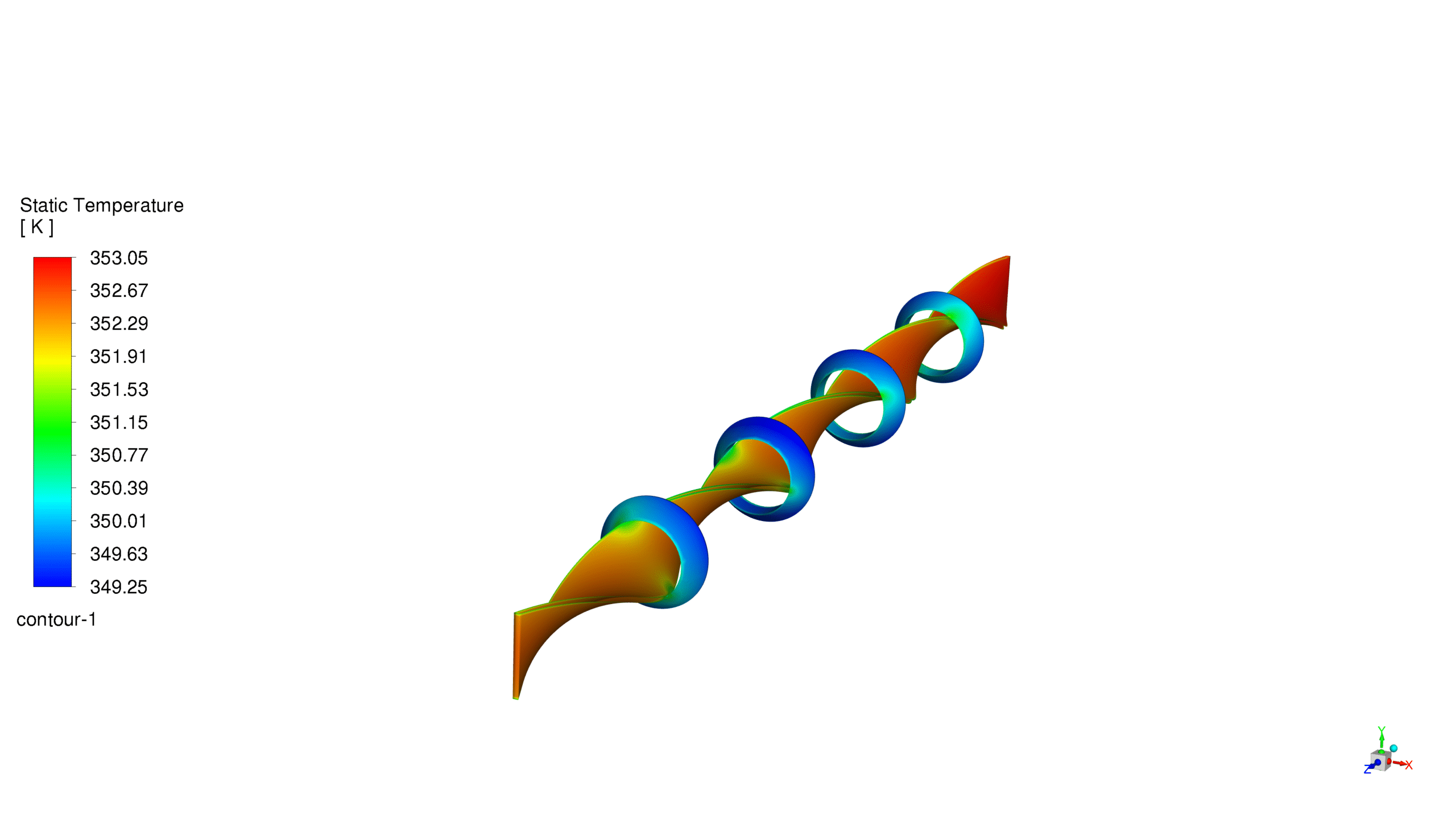

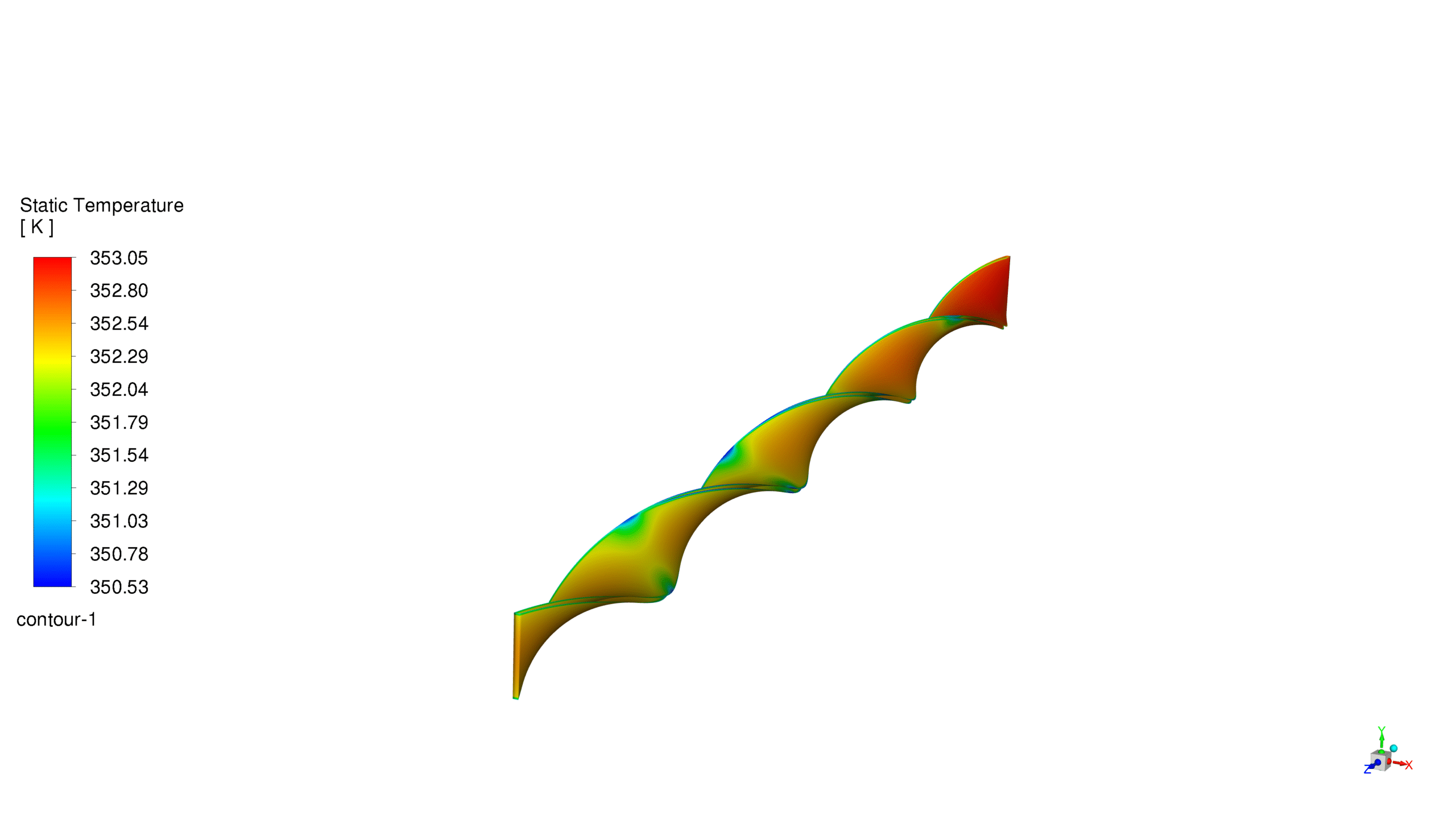

The temperature contours clearly show the cooling effect as the nanofluid flows through the tube. The inlet temperature of the nanofluid is 353.15K, and it cools down to 352.50K at the outlet. The air inlet temperature is 298.15K, which increases to 323.31K at the outlet due to heat transfer from the nanofluid.

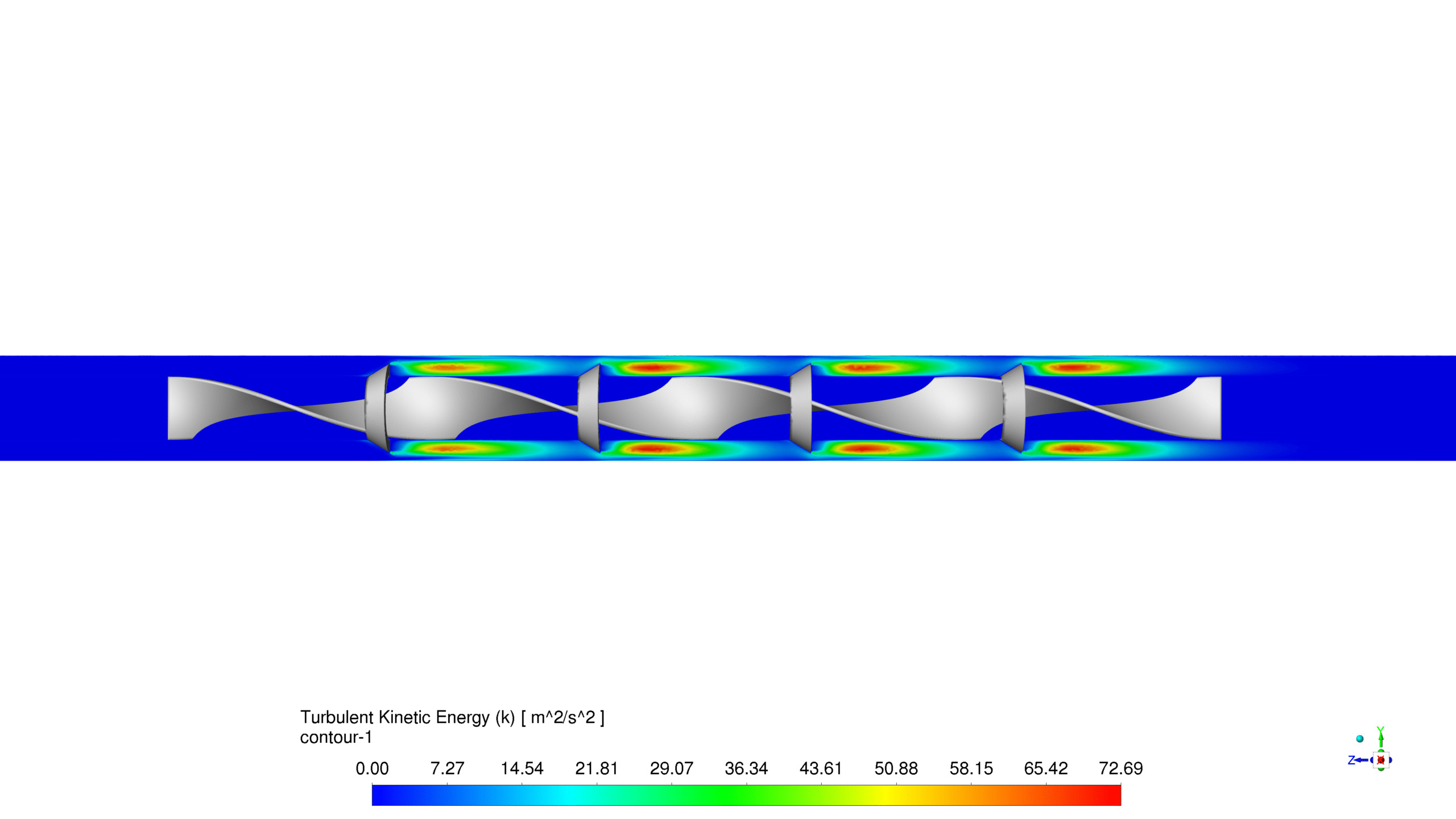

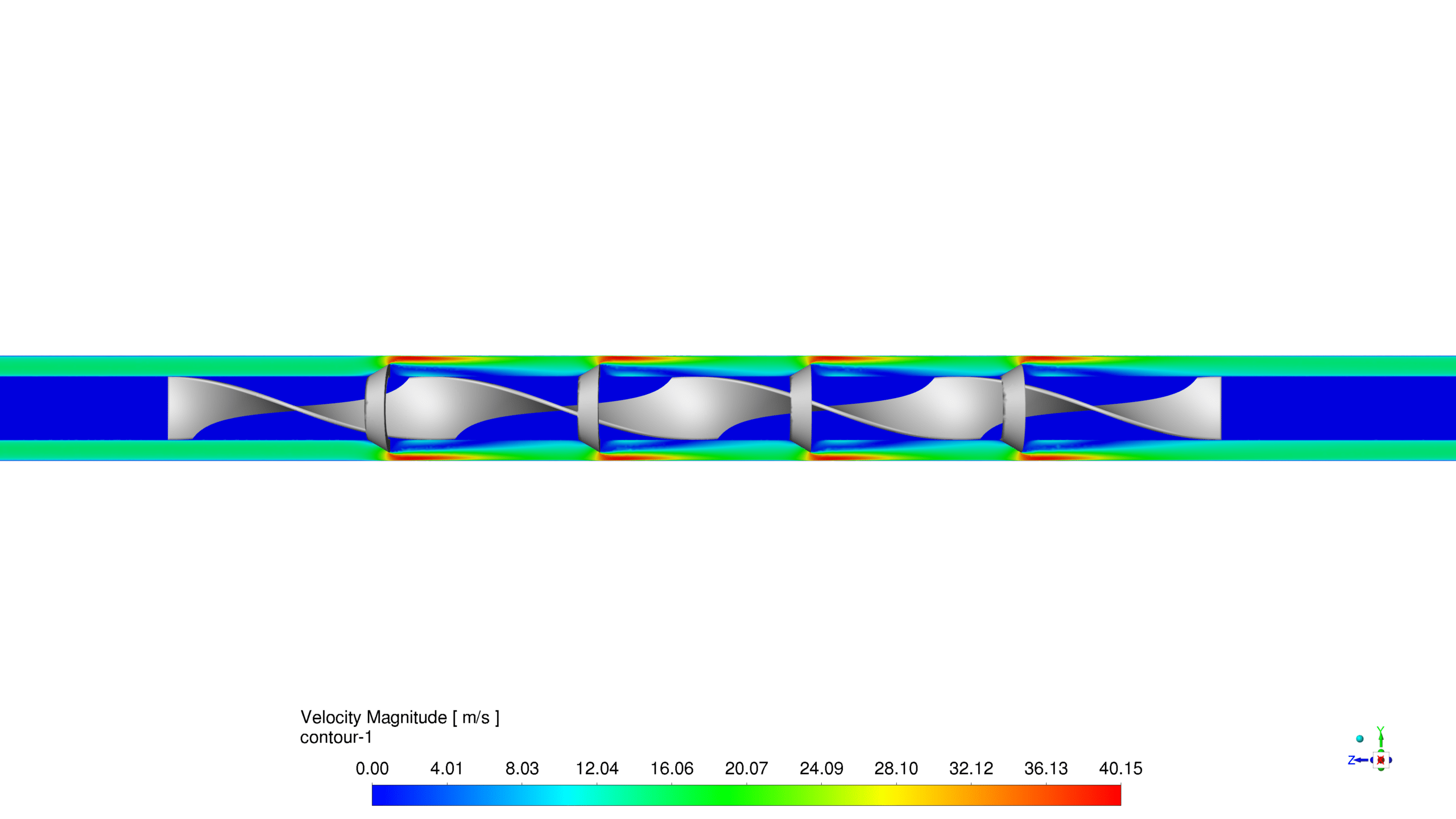

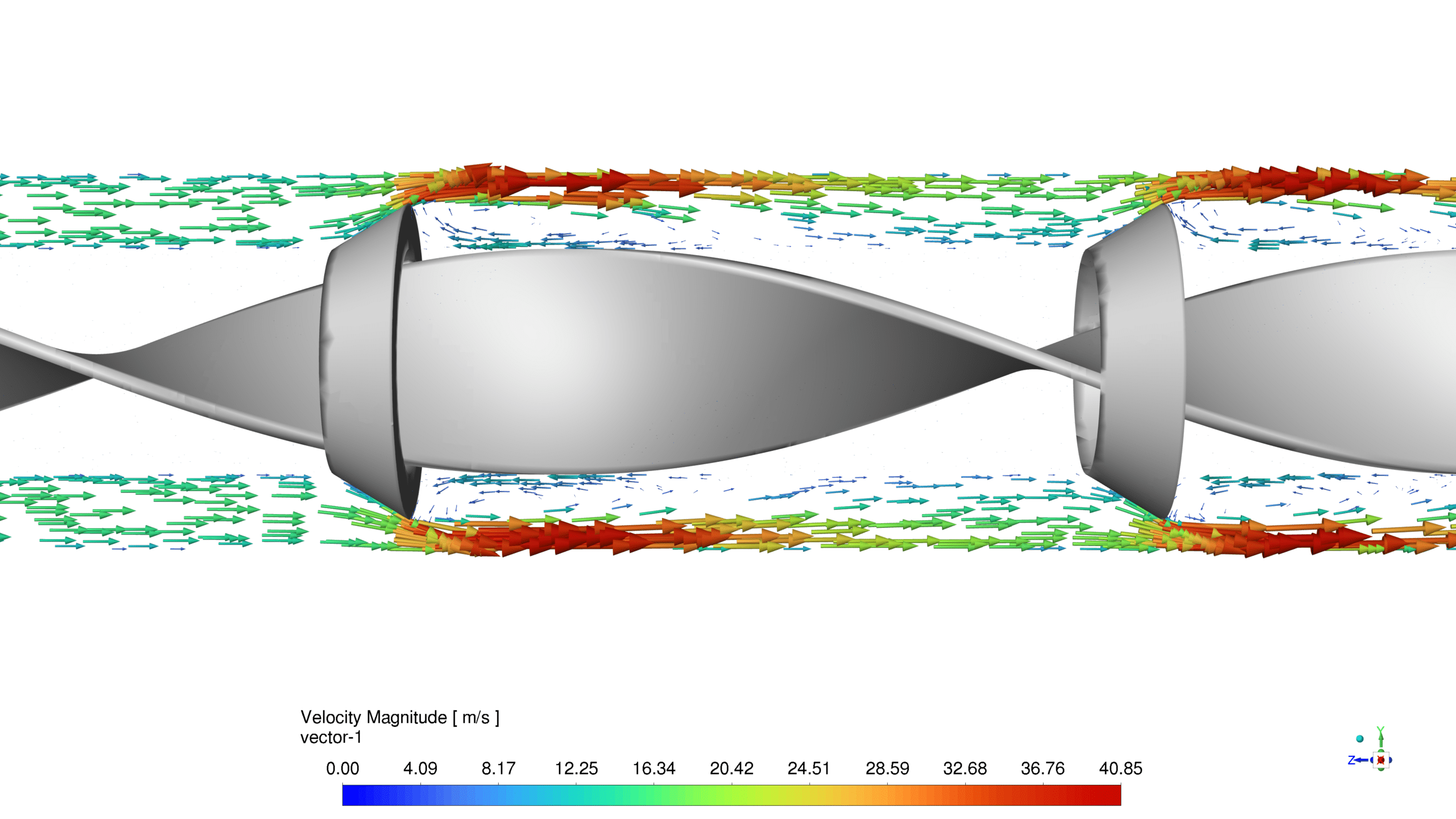

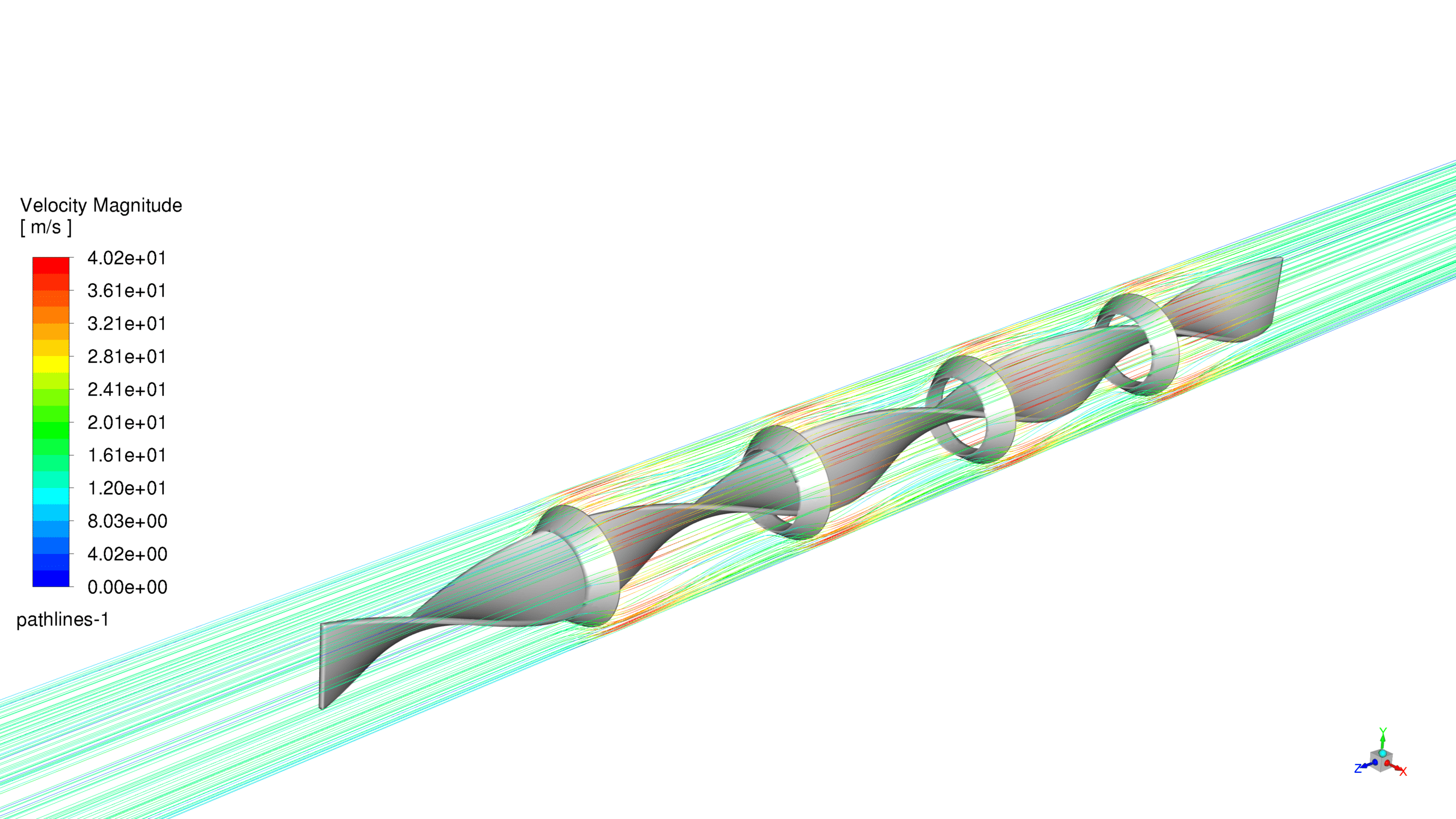

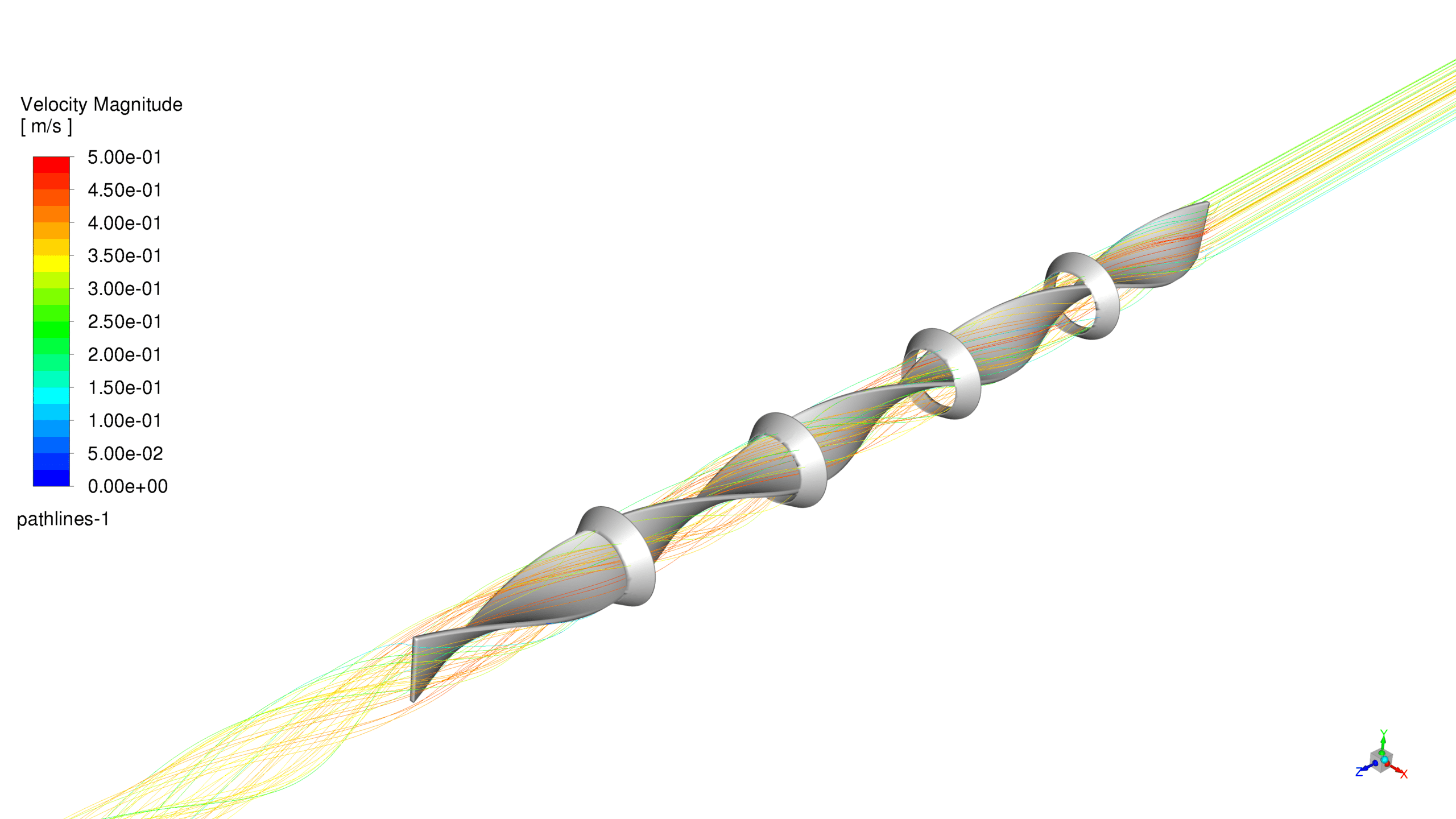

The velocity pathlines and velocity magnitude contours show complex flow patterns within the tube. The flow accelerates as it passes through the twisted tape and vortex generator regions, reaching velocities up to 0.5 m/s. The twisted tape creates a swirling motion, enhancing fluid mixing and heat transfer. The turbulent kinetic energy contour shows higher values near the vortex generators and in the wake regions, reaching up to 72.69 m²/s². This increased turbulence enhances mixing and heat transfer in these areas.

The velocity vector plots provide detailed insight into the flow direction and magnitude within the tube. They highlight areas of high velocity near the vortex generators and in the core flow, which is crucial for understanding the heat transfer mechanisms.

The simulation results demonstrate the complex interplay between fluid flow and heat transfer in the tube with twisted tape inserts and vortex generators. The geometry significantly influences the flow patterns, creating regions of high velocity and turbulence, which in turn affect the heat transfer characteristics. The cooling of the nanofluid as it passes through the tube is evident, with the temperature dropping from 353.15K at the inlet to 352.50K at the outlet.

Reviews

There are no reviews yet.