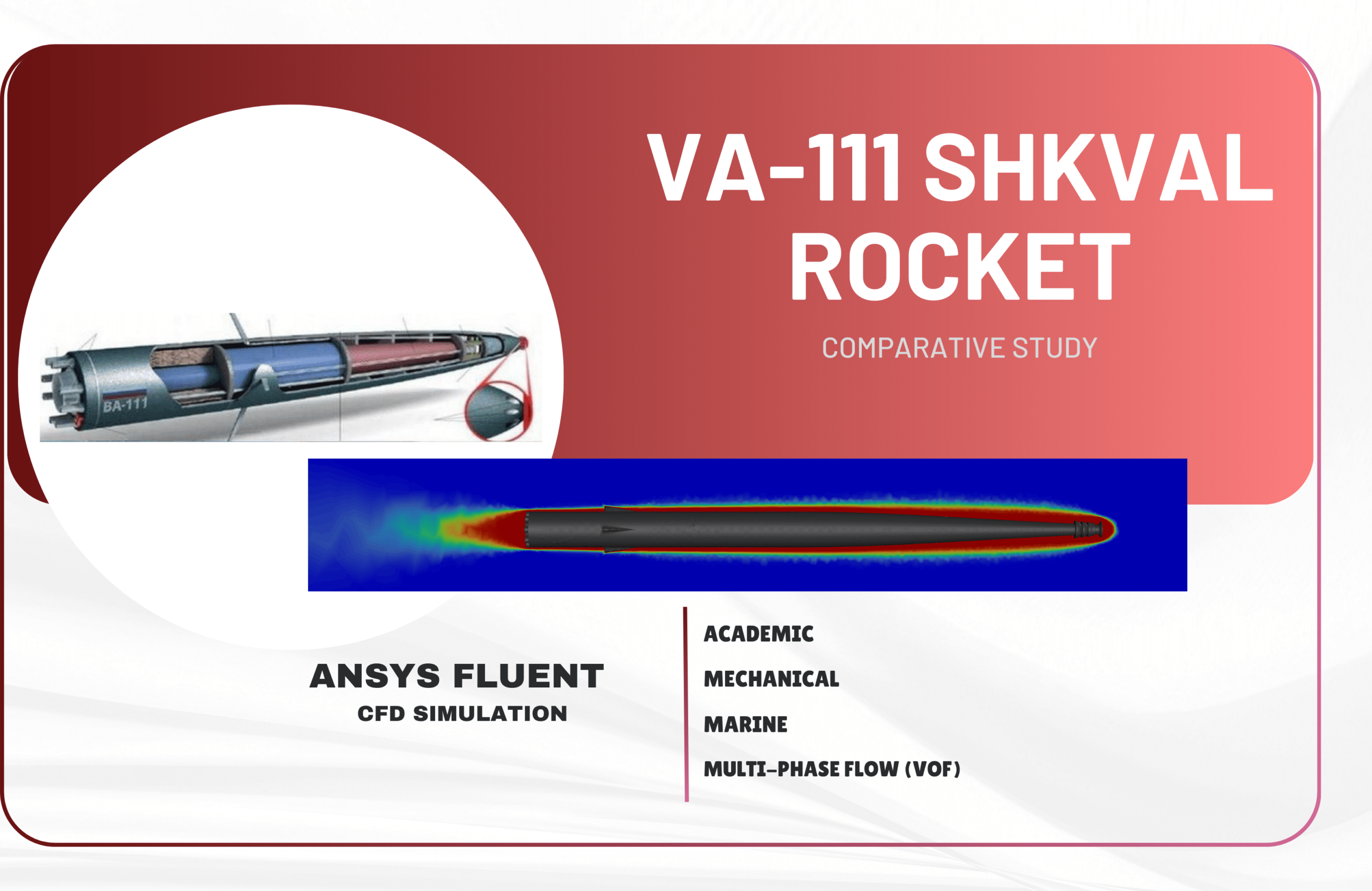

VA-111 Shkval Rocket Performance Comparative Study with and without Supercavitation injection

$140.00 $70.00 Student Discount

- This problem simulates a VA-111 Shkval rocket using ANSYS Fluent software.

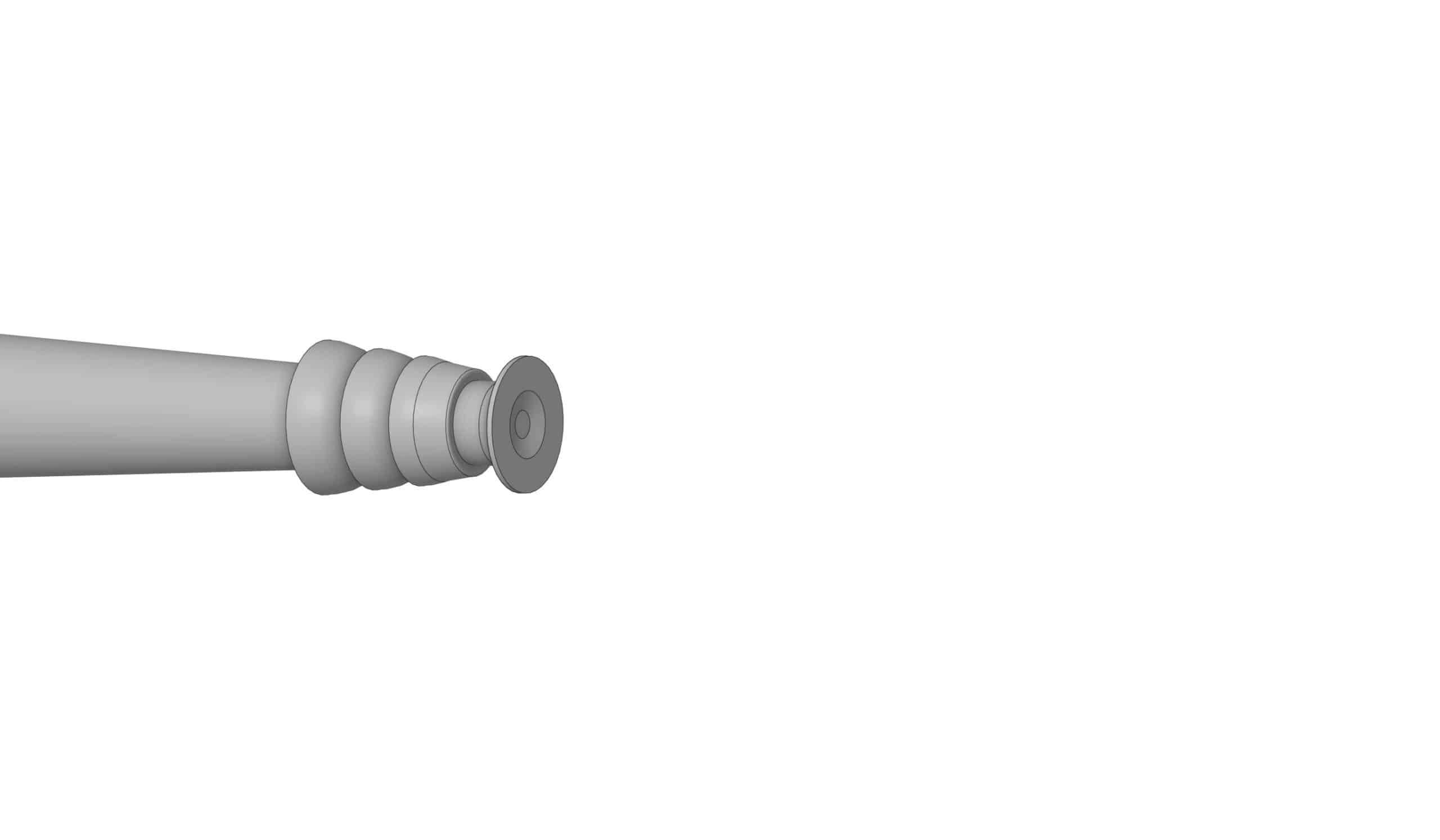

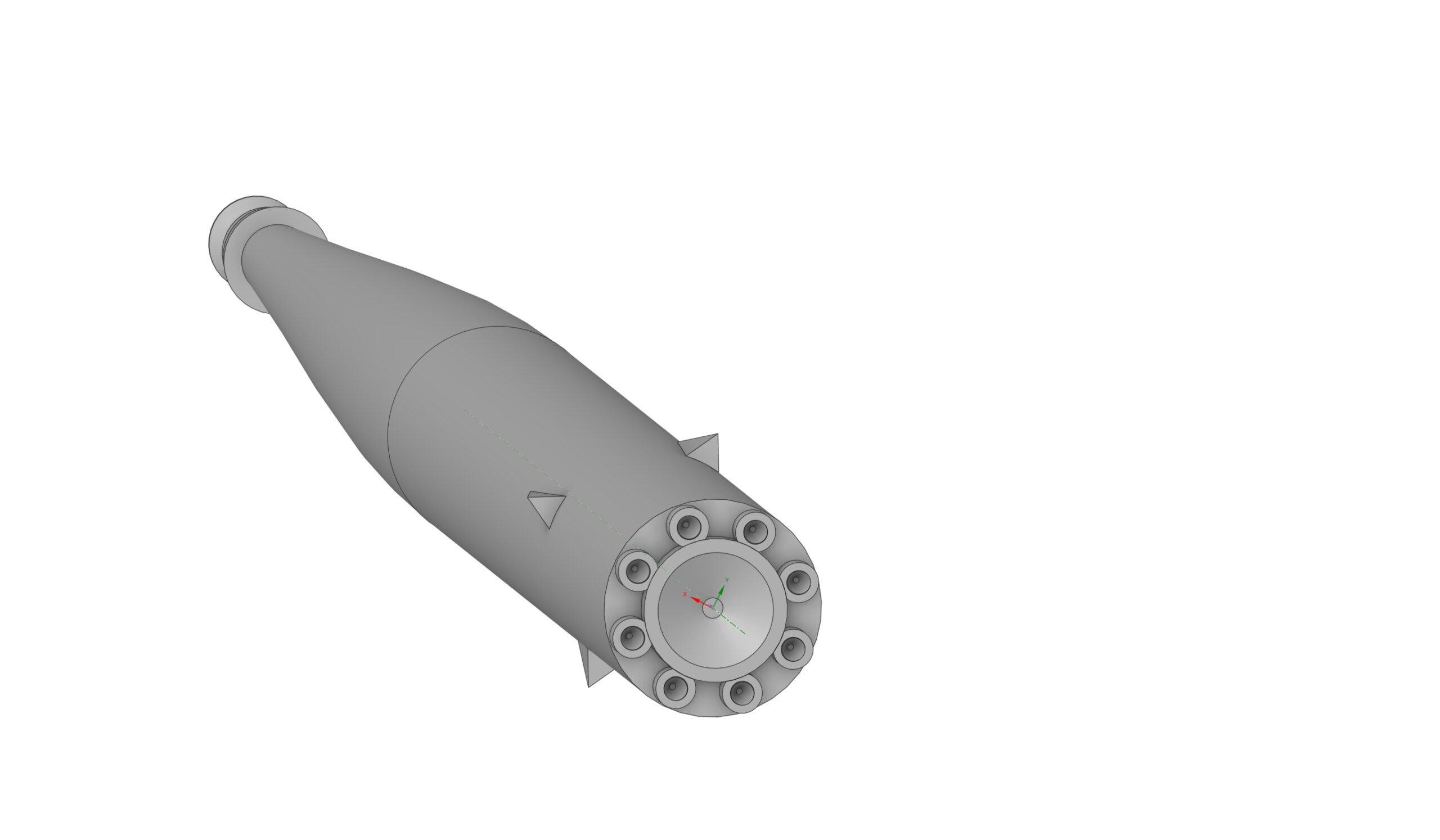

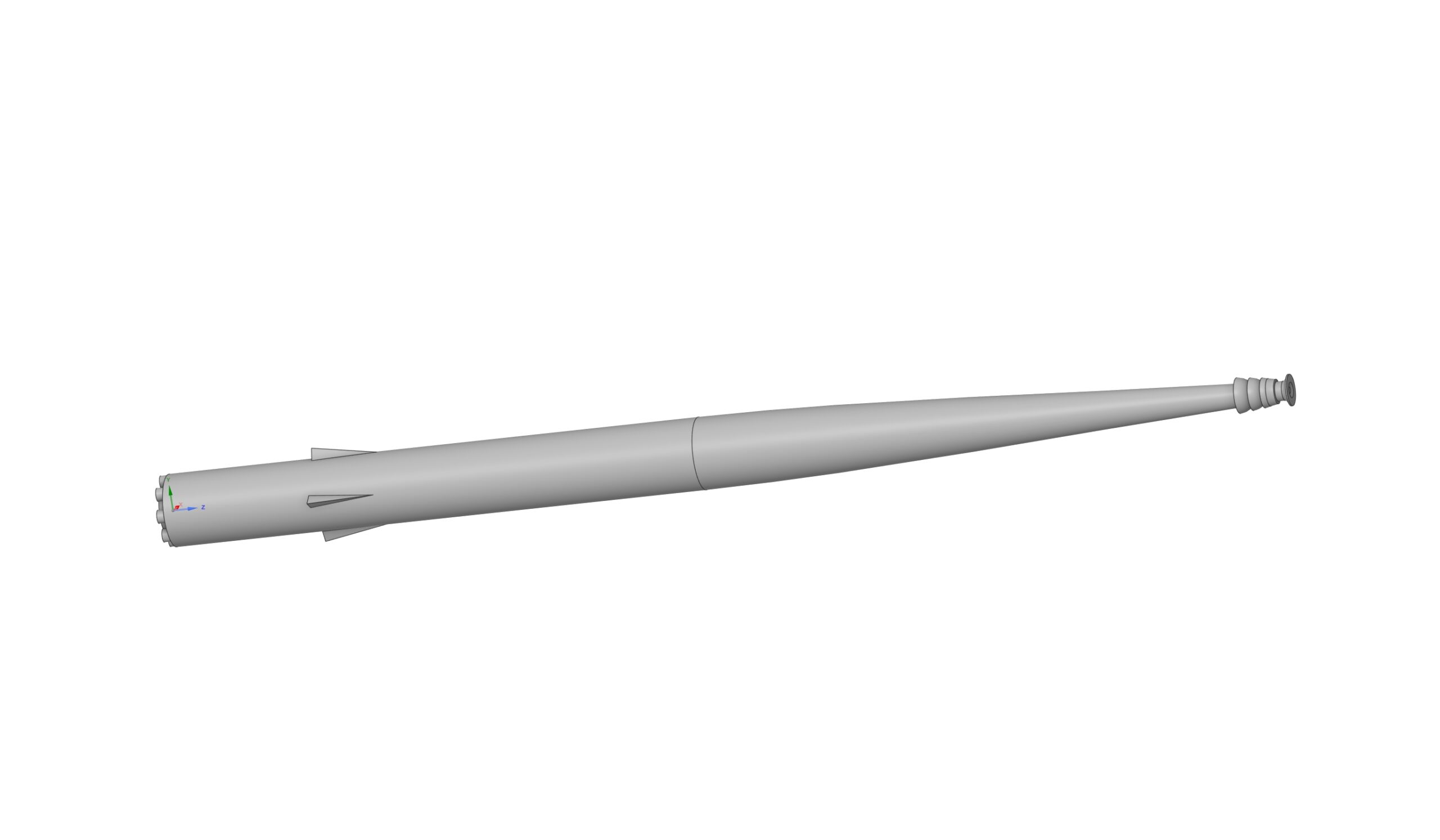

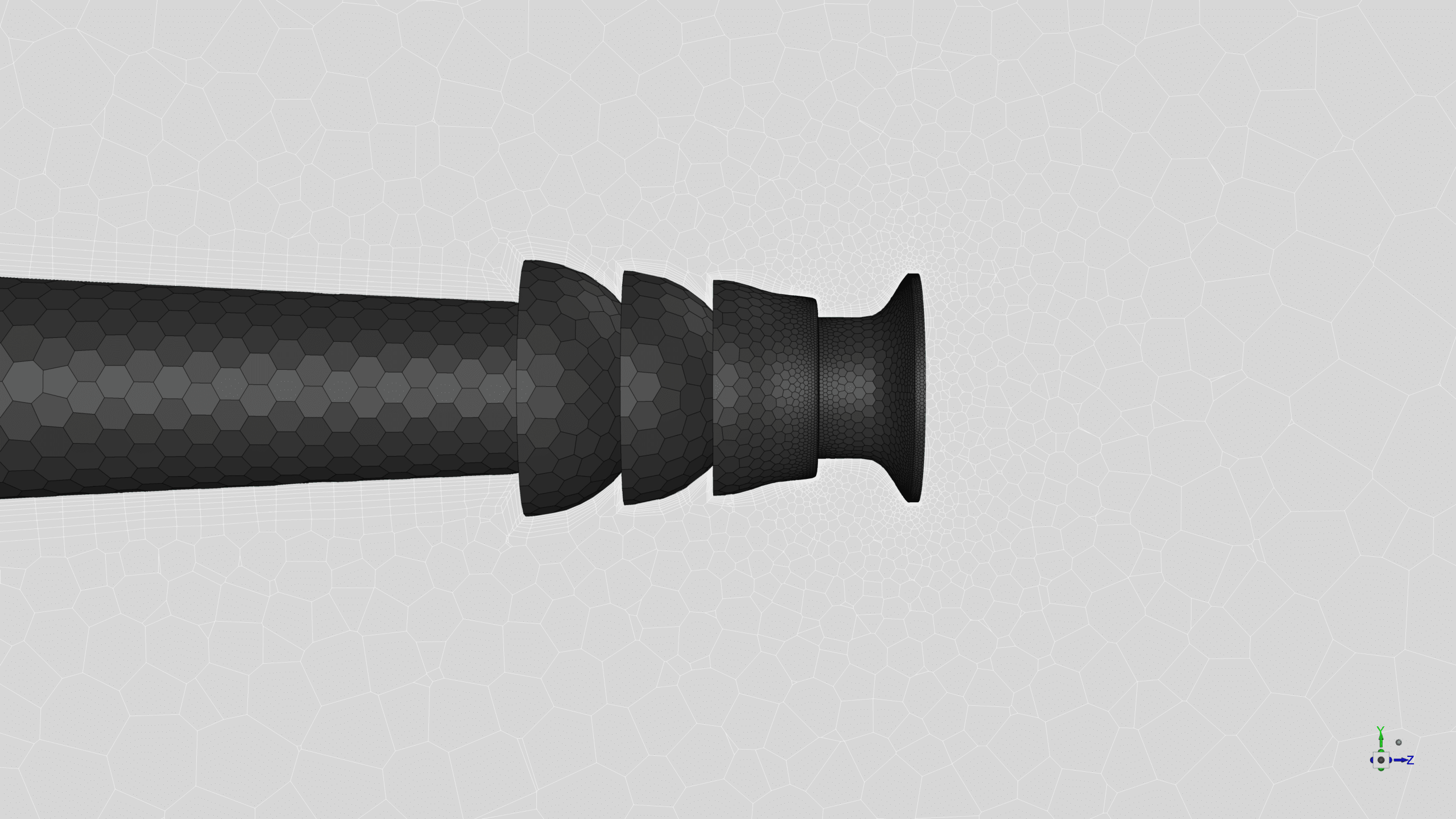

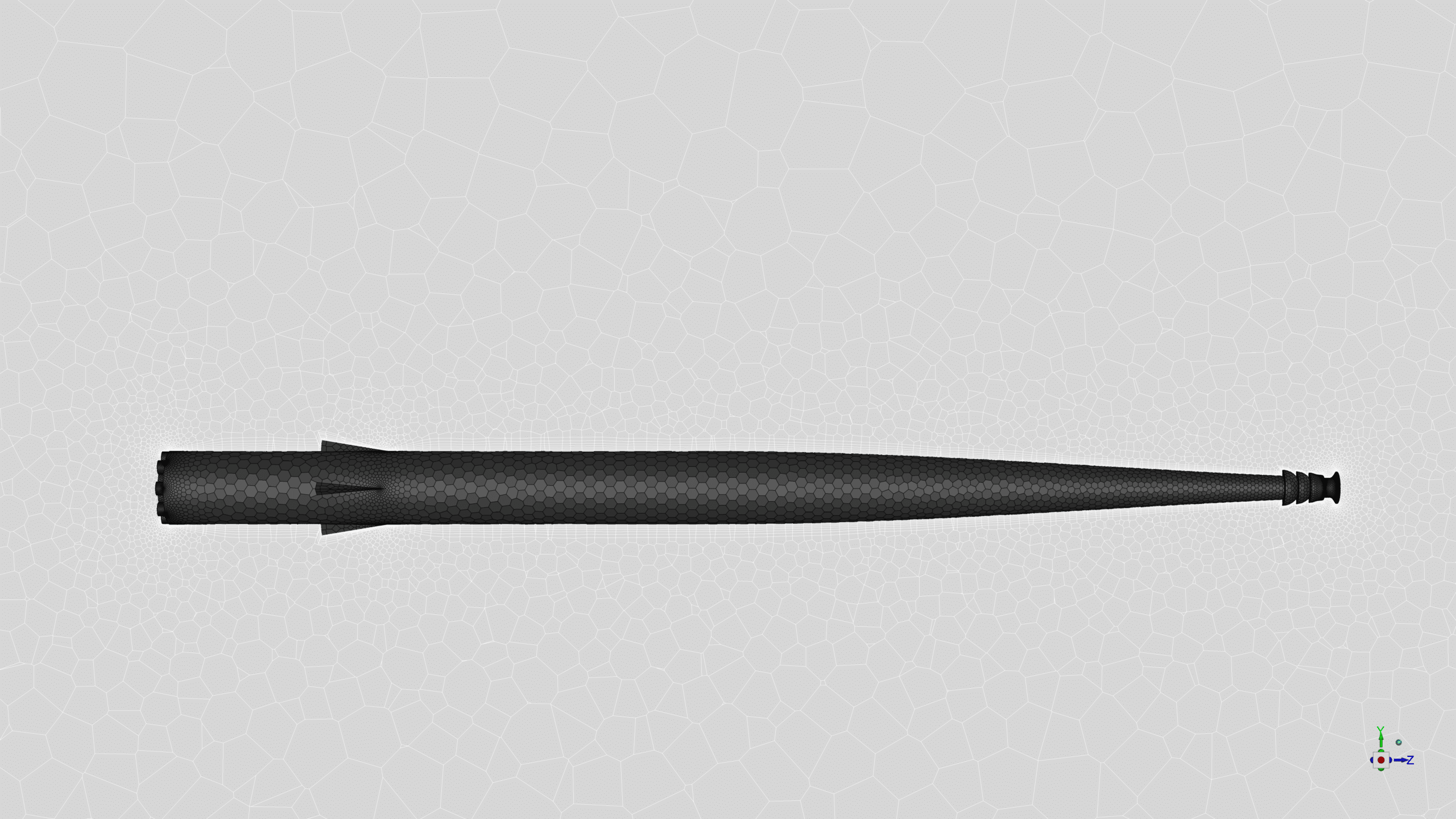

- The geometry is designed in SpaceClaim, and the meshing is performed using Fluent Meshing; the element number equals 257,000 polyhedral cells.

- The simulation uses the Pressure-based and VOF Multiphase model to define a two-phase flow.

- The turbulence model is set to SST k-ω.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

VA-111 Shkval Rocket are high-speed supercavitating torpedoes that rely on the formation of a cavitation bubble to reduce hydrodynamic drag and achieve speeds exceeding 200 knots (102.8 m/s). While cavitation plays a crucial role in the performance of these rockets, simulating the aerodynamics without capturing the cavitation effects can provide valuable insights into the overall flow characteristics and aerodynamic behavior. This study focuses on the aerodynamic simulation of VA-111 Shkval Rocket using Computational Fluid Dynamics (CFD) techniques, neglecting the cavitation modeling.

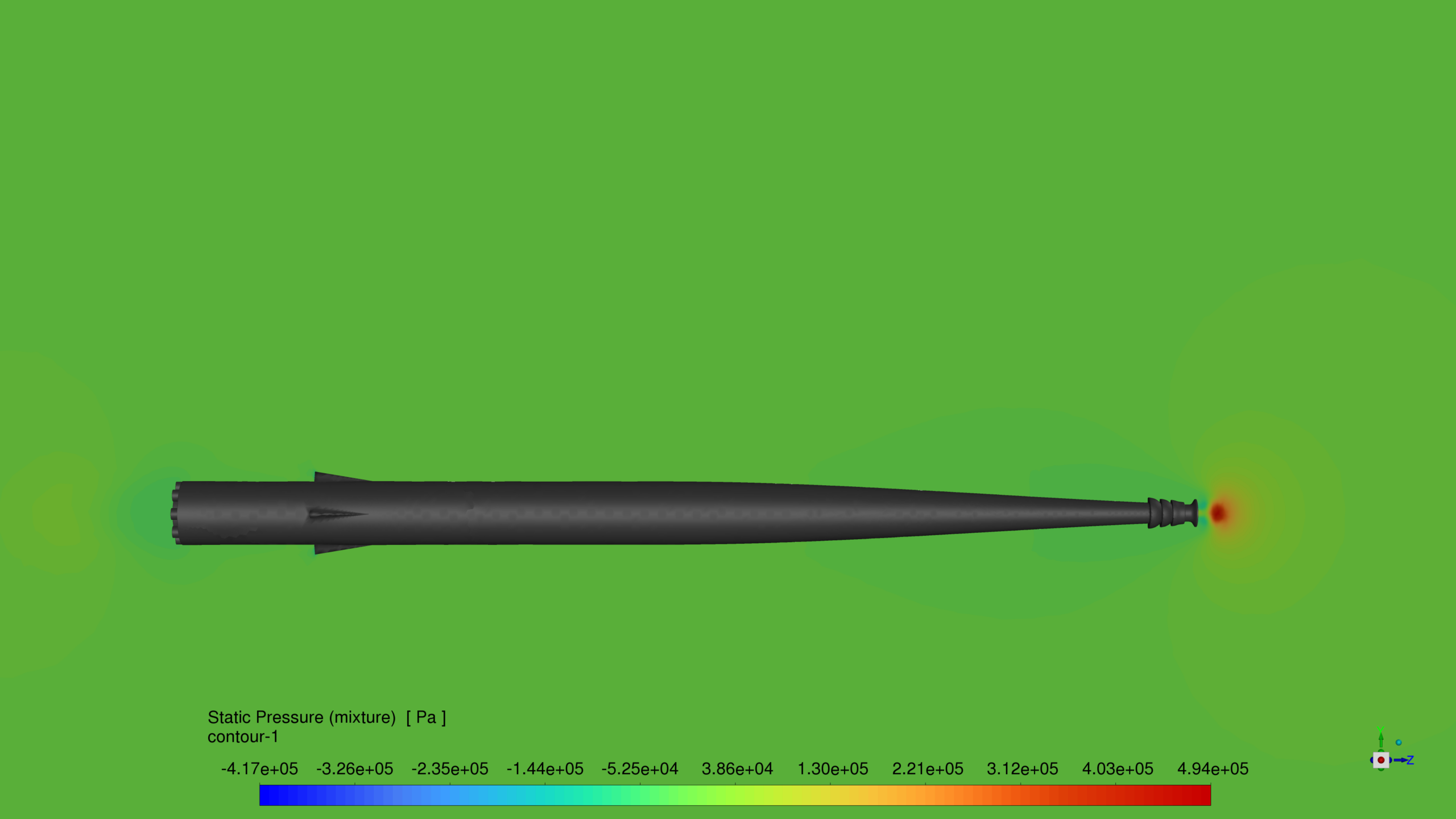

This study uses ANSYS Fluent software to compare the performance of a VA-111 Shkval rocket with and without supercavitation. The objective is to quantify the drag reduction achieved through supercavitation and analyze the impact on the rocket’s aerodynamic characteristics.

The geometry of the VA-111 Shkval Rocket is designed using SpaceClaim, and the meshing is performed using Fluent Meshing, resulting in a polyhedral mesh with 257,000 cells. Two simulations are conducted: one with air injection to induce supercavitation and another without air injection, representing a single-phase flow.

Methodology

The SST k-ω turbulence model is used to accurately predict the complex turbulent flow around the rocket, and the Pressure-based solver is utilized to solve the governing equations.

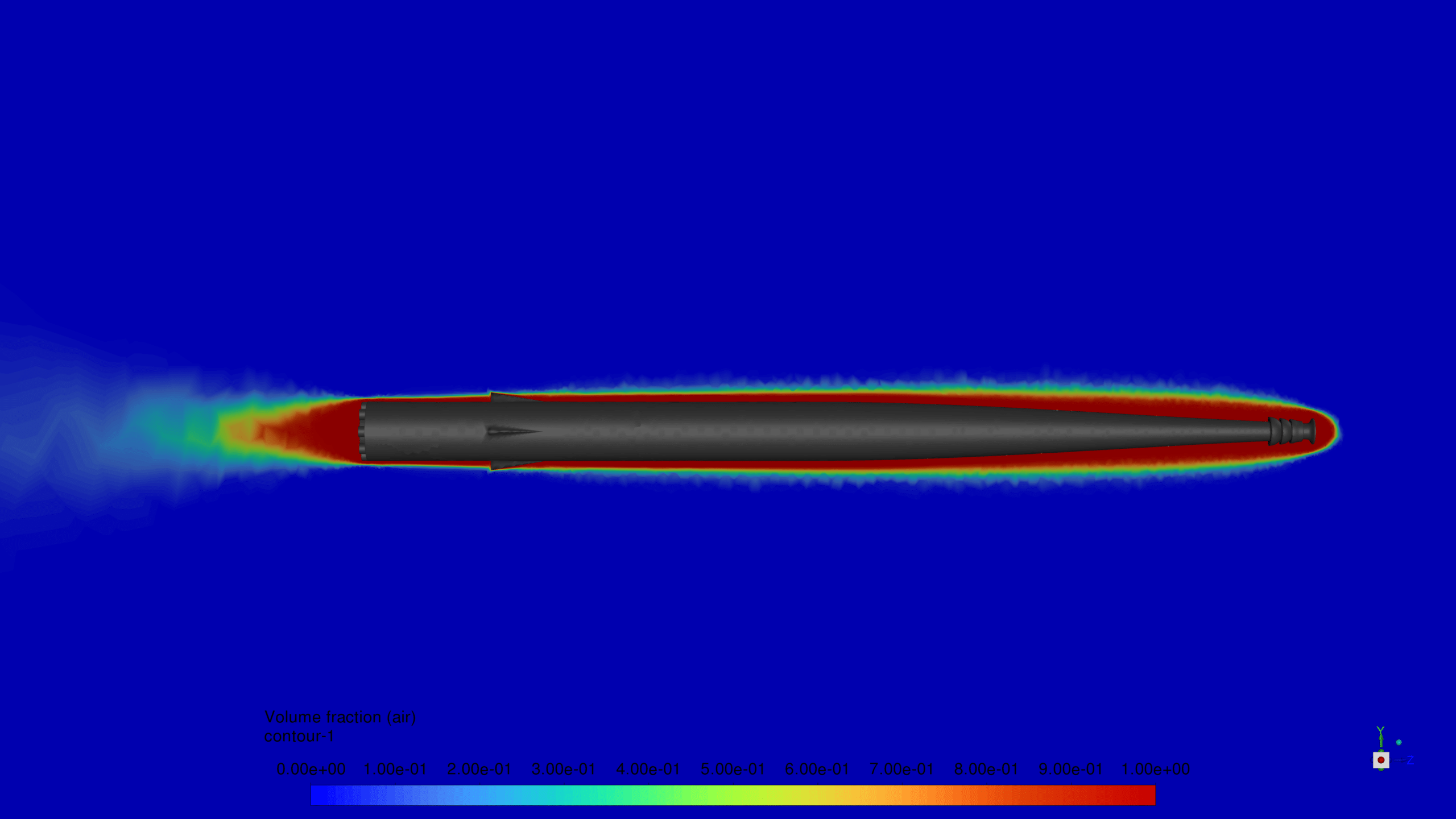

In the supercavitation case, the Volume of Fluid (VOF) Multiphase model is employed to capture the two-phase flow behavior, considering water and air phases.

The boundary conditions for the supercavitation case include a velocity inlet for the water, a pressure outlet, and symmetry conditions for the remaining boundaries. The air injection is also modeled using a velocity inlet boundary condition.

For the non-supercavitation case, the same geometry, mesh, turbulence model, and solver settings are used, but the simulation is conducted considering only water as a single phase, without air injection.

Result

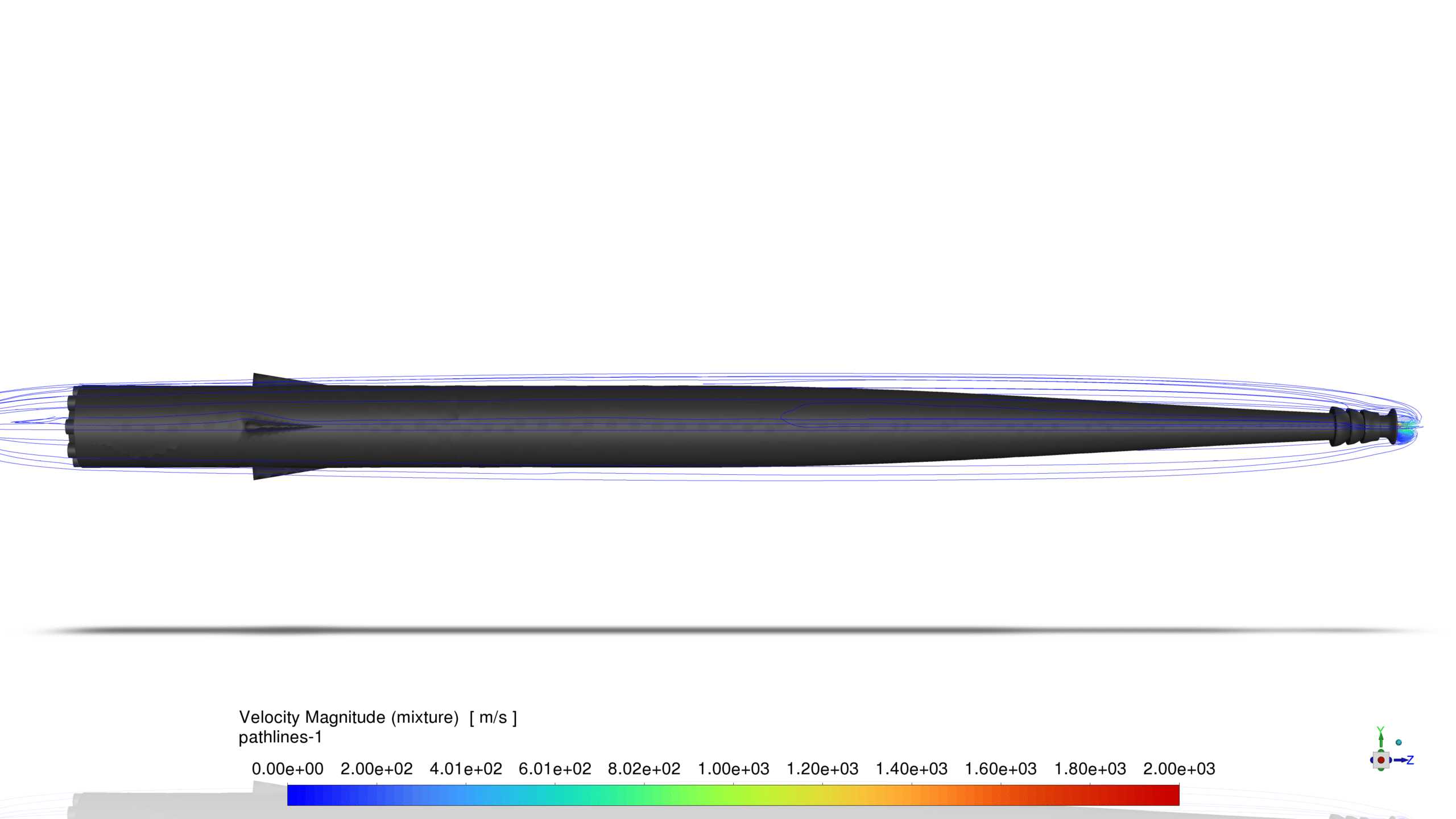

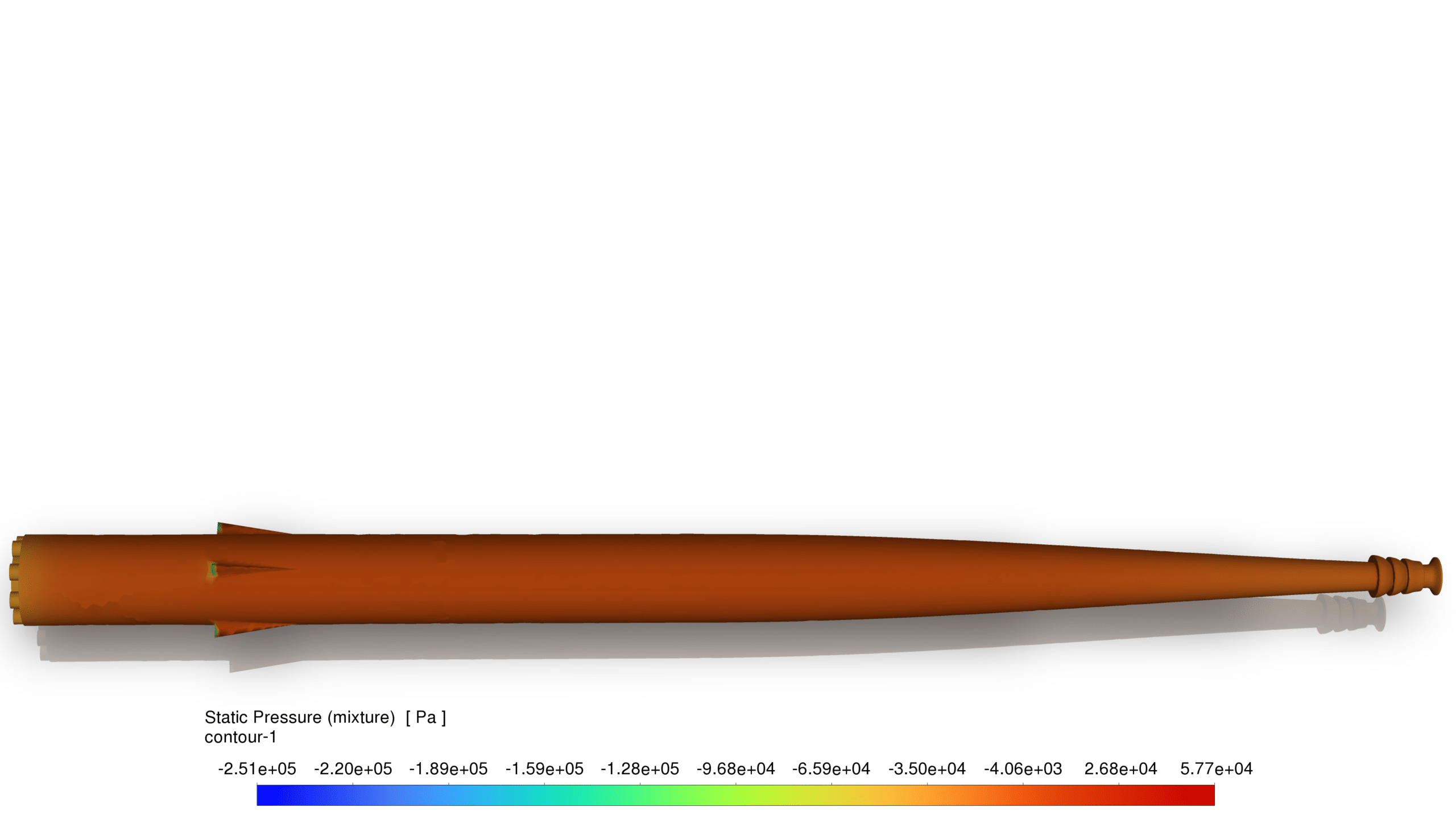

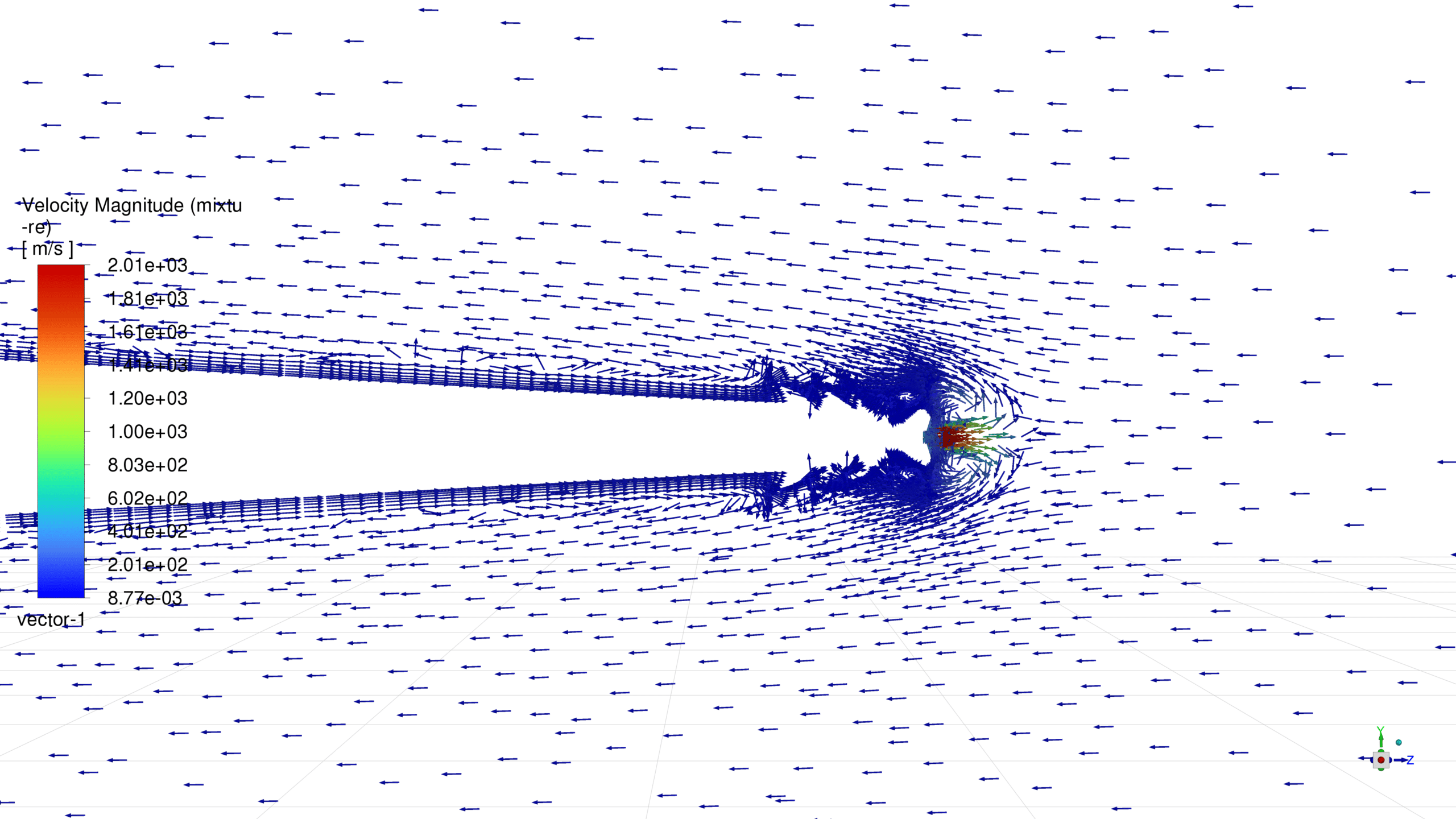

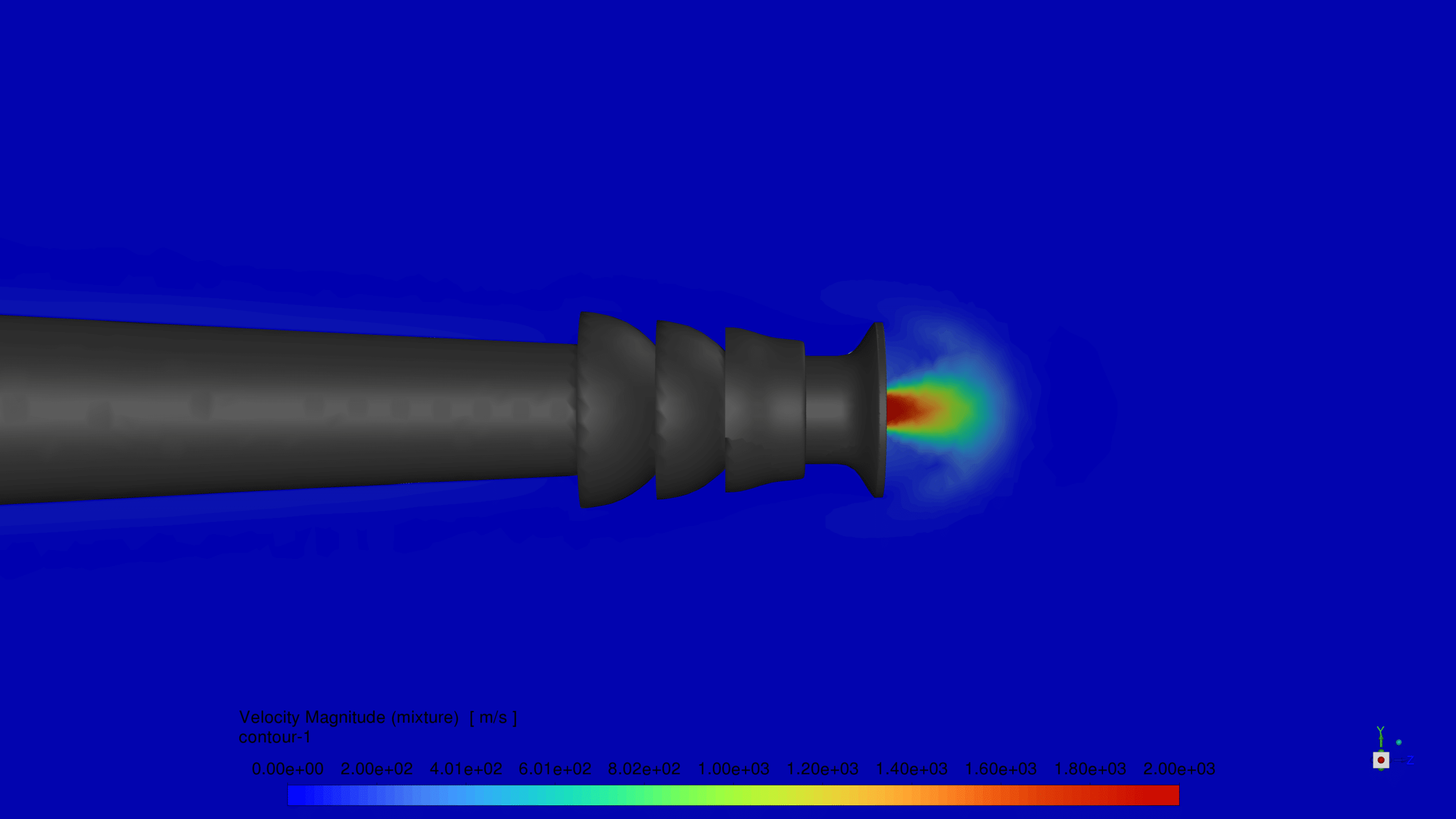

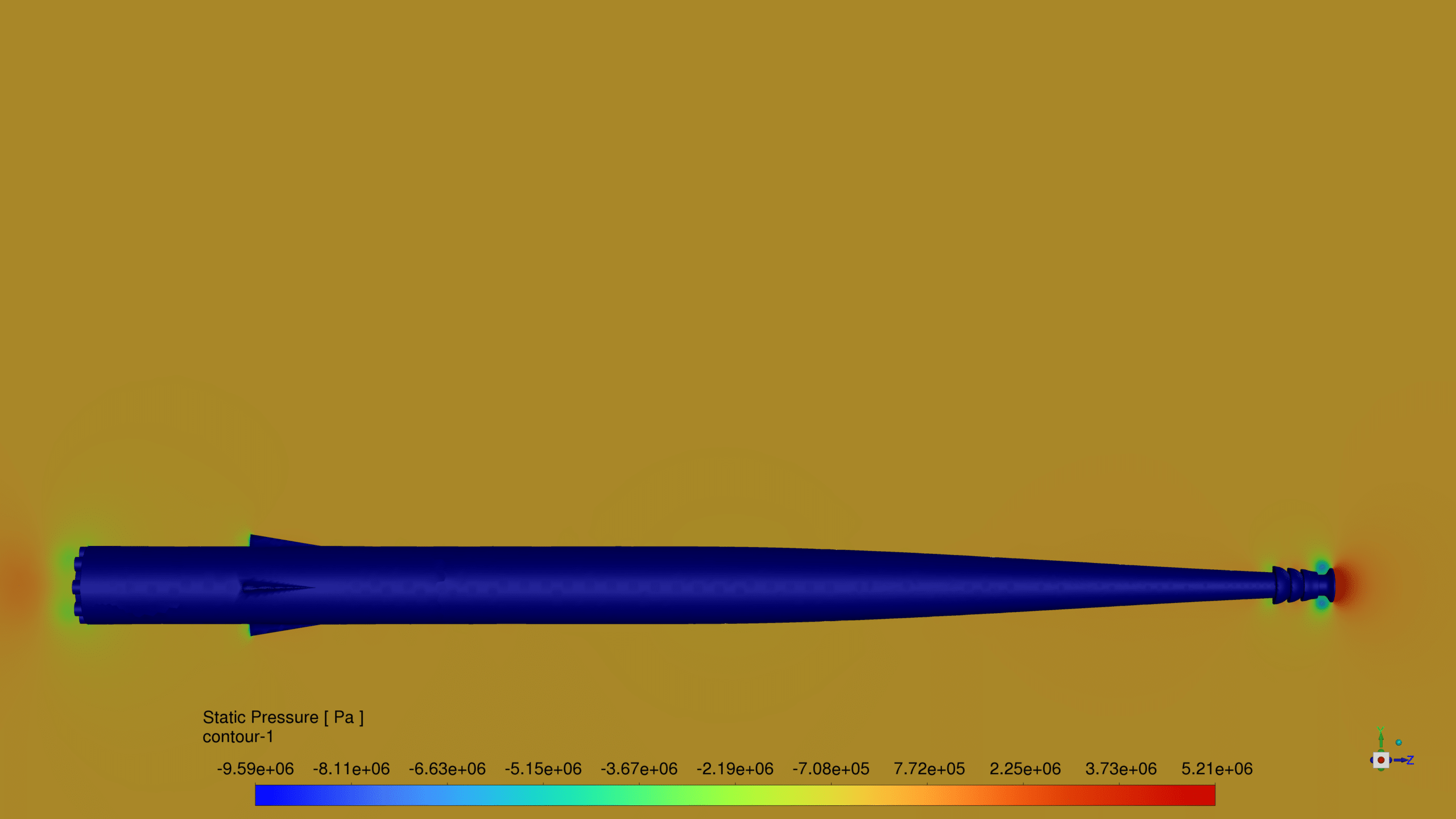

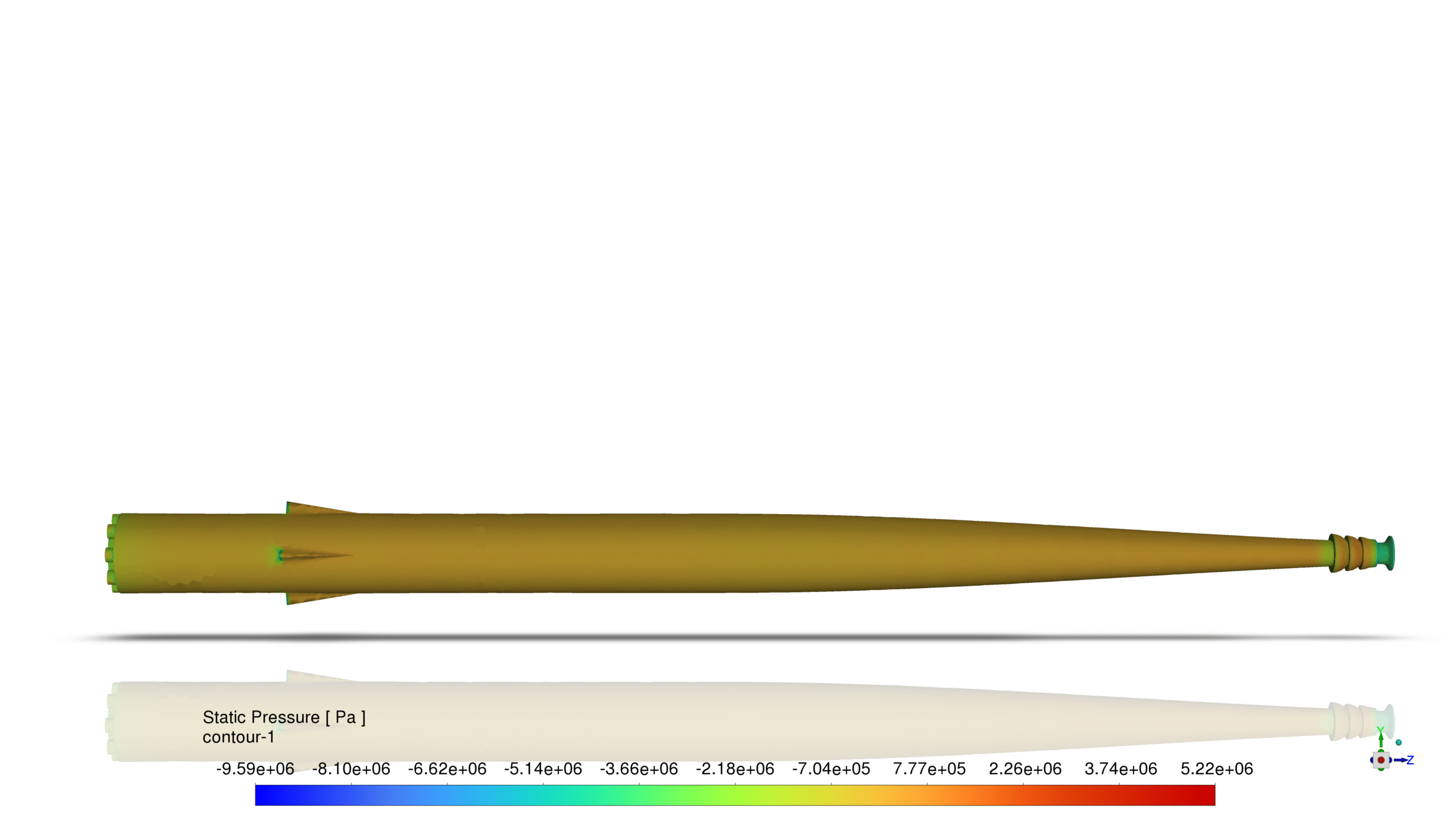

The significant drag reduction observed in the supercavitation case can be attributed to the formation of a vapor cavity around the rocket. When air is injected at a high velocity (2000 m/s in this case), it creates a low-pressure region around the rocket, causing the surrounding water to vaporize and form a cavity. This vapor cavity envelops a large portion of the rocket’s surface, effectively reducing the wetted area and minimizing the direct contact between the rocket and the water.

Inside the vapor cavity, the density and viscosity of the fluid are much lower compared to water, resulting in a substantial decrease in skin friction drag. The VA-111 Shkval Rocket essentially travels through a mixture of water vapor and injected air, which offers significantly less resistance than water alone. This phenomenon is known as supercavitation, and it enables the rocket to achieve high speeds with minimal drag.

The results show a significant drag reduction when supercavitation is employed. In the non-supercavitation case, the drag force is found to be 942,000 N, while in the supercavitation case with air injection, the drag force is drastically reduced to 12411N.

However, it’s important to note that the air injection itself can introduce additional drag forces. The injected air interacts with the surrounding flow field and can create turbulence and mixing at the interface between the air and water. This interaction can lead to some drag forces acting on the rocket.The drag force caused by air injection in a supercavitating rocket can be complex to formulate accurately, as it involves the interaction between the injected air and the surrounding water. However, a simplified approach to estimate the air injection drag can be based on the momentum change of the injected air. Here’s a general formulation for the air injection drag:

Air Injection Drag = ṁ × (v_air – v_rocket)

In the supercavitation case, the drag force of 12411N includes the combined effects of the reduced skin friction drag due to the vapor cavity and any additional drag forces introduced by the air injection. While the air injection drag is present, it is relatively small compared to the substantial reduction in skin friction drag achieved through supercavitation. In the supercavitation case, the air injection force of 8,840 N is an additional force acting on the VA-111 Shkval Rocket due to the momentum change of the injected air. This force is separate from the pressure drag and viscous drag forces that arise from the interaction between the rocket and the surrounding fluid.

It’s worth mentioning that the drag reduction achieved through supercavitation is highly dependent on the specific design of the rocket, the air injection system, and the operating conditions. Factors such as the air injection velocity, the location and configuration of the injection ports, and the rocket’s geometry can all influence the effectiveness of supercavitation and the associated drag reduction.

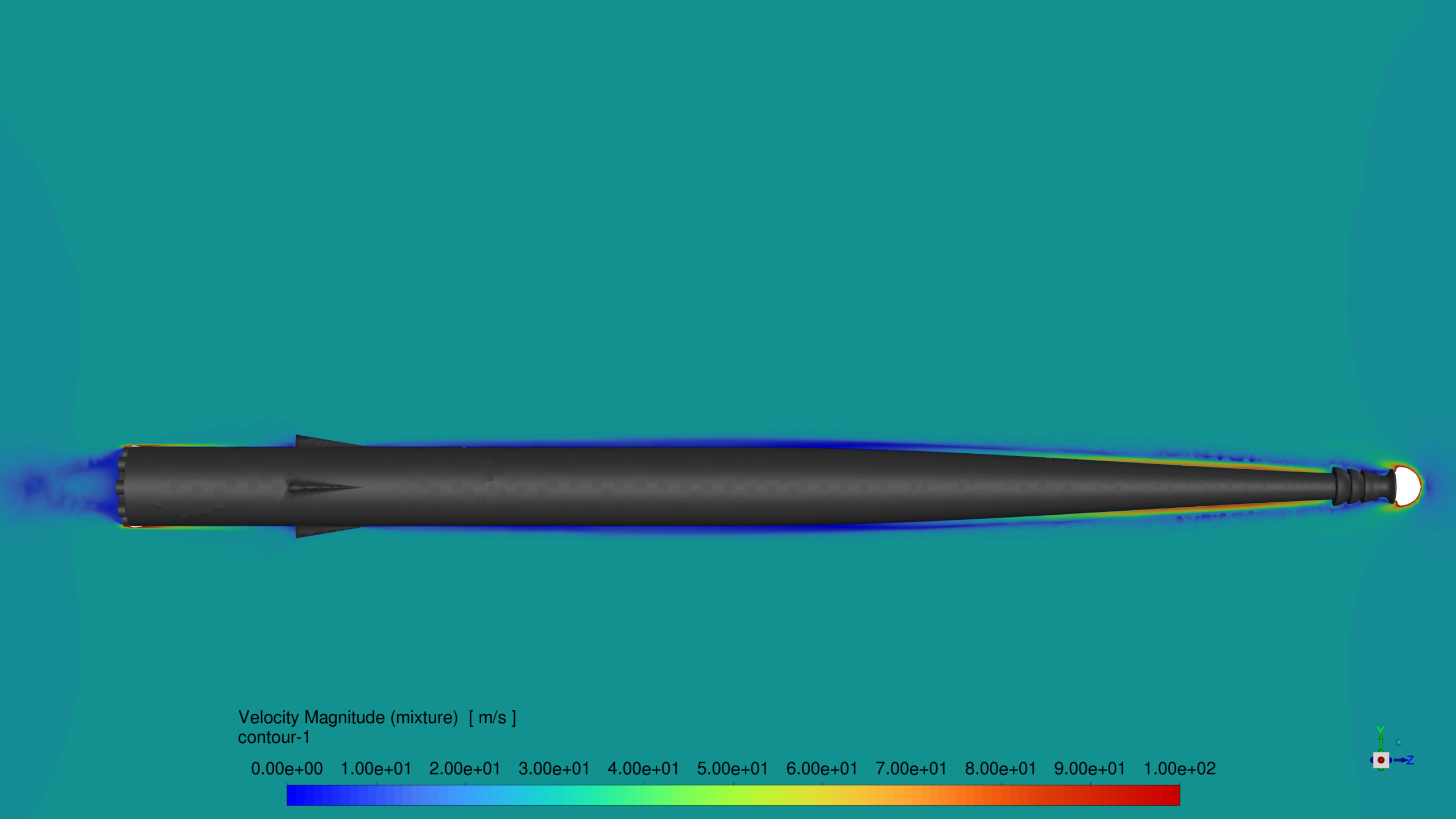

Flow field analysis is performed for both cases, examining velocity contours, pressure distribution, and streamlines. The presence or absence of the supercavitation bubble and its impact on the flow characteristics are assessed.

Reviews

There are no reviews yet.