Vertical shell and tube liquid sodium Heat Exchanger

$80.00 $40.00 Student Discount

In this project, a Vertical Heat Exchanger has been simulated, and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Vertical shell and tube Heat Exchanger (liquid sodium), Ansys Fluent CFD Simulation Training

The present simulation is about heat transfer in a vertical heat exchanger via ANSYS Fluent. A Heat exchanger is an industrial equipment whose main task is to heat transfer between its hot and cold sides. In this project, a vertical shell and tube heat exchanger are modeled.

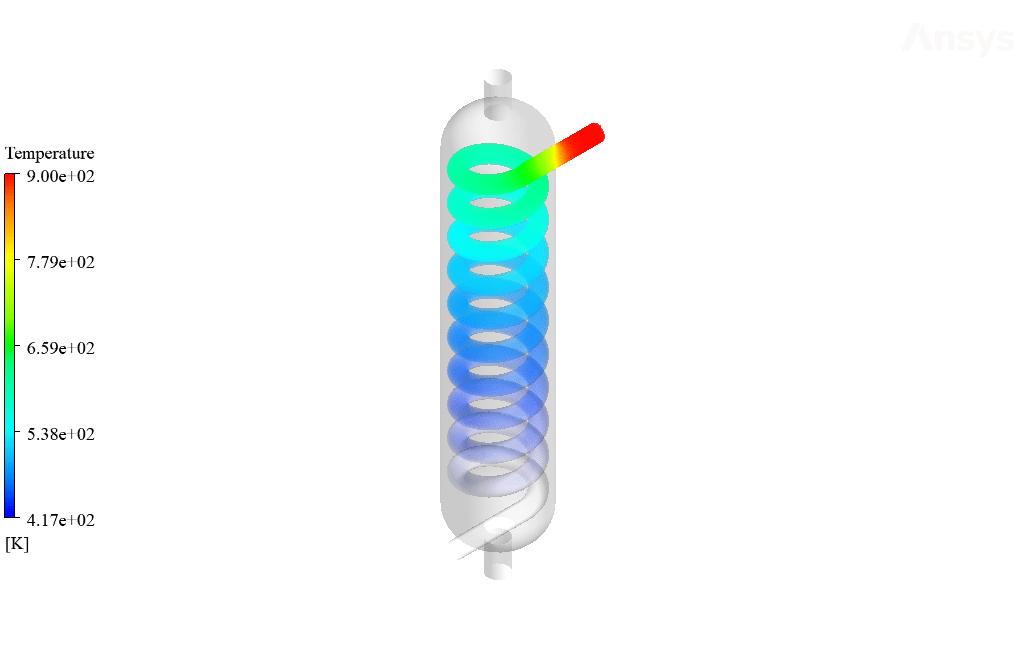

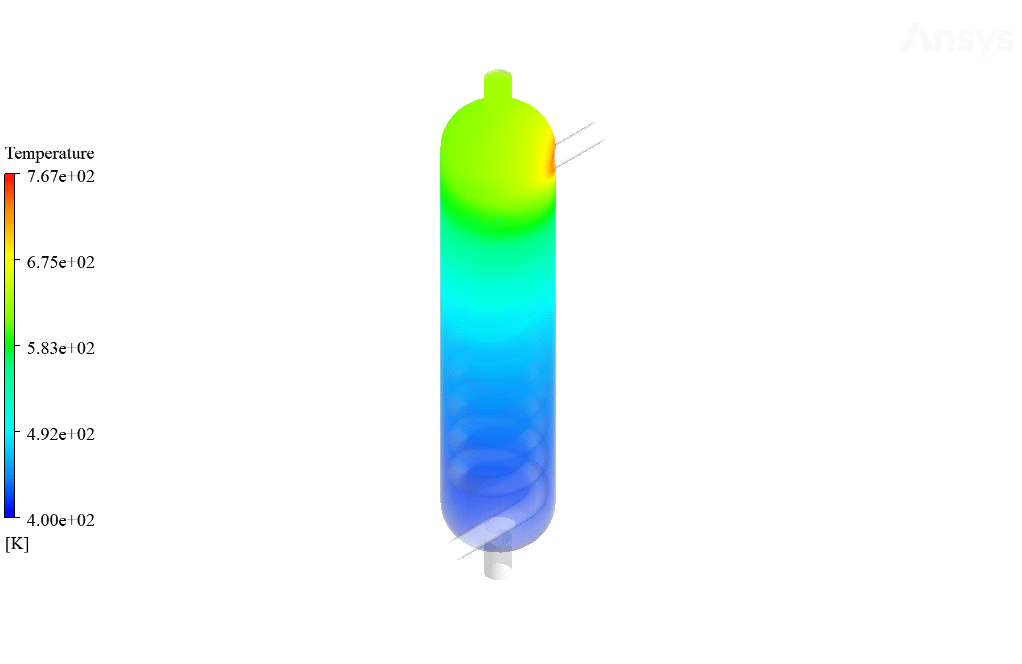

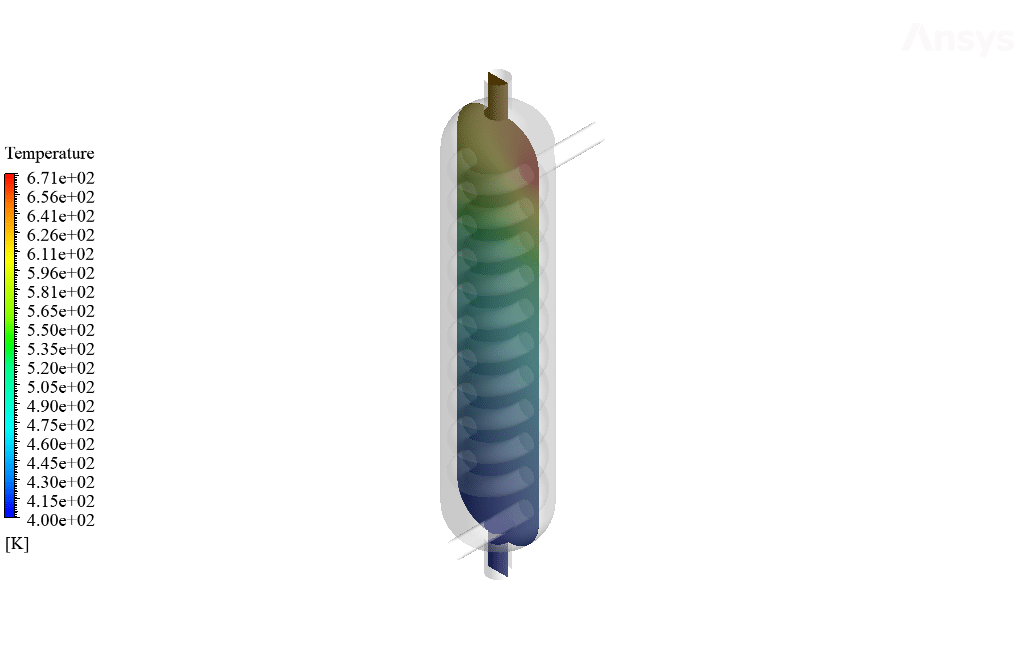

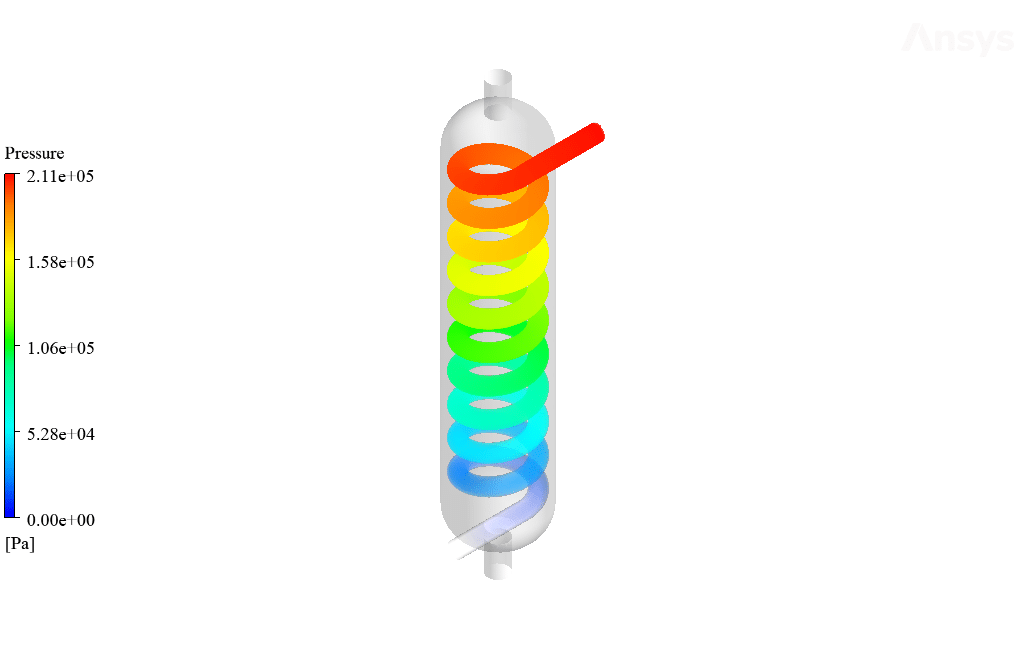

The fluid used in this heat exchanger is liquid sodium. Sodium flow with a temperature of 900 K and a velocity of 1.5 m / s inside the helical tubes moves from the top of the heat exchanger to the bottom.

Sodium flow with a temperature of 400 K and a velocity of 1.5 m / s inside the cylindrical shell of the heat exchanger moves from down to the top.

The thermophysical properties of liquid sodium are defined as a function of temperature. Thus, density, specific heat capacity, thermal conductivity, and viscosity change at different temperatures.

Geometry & Mesh

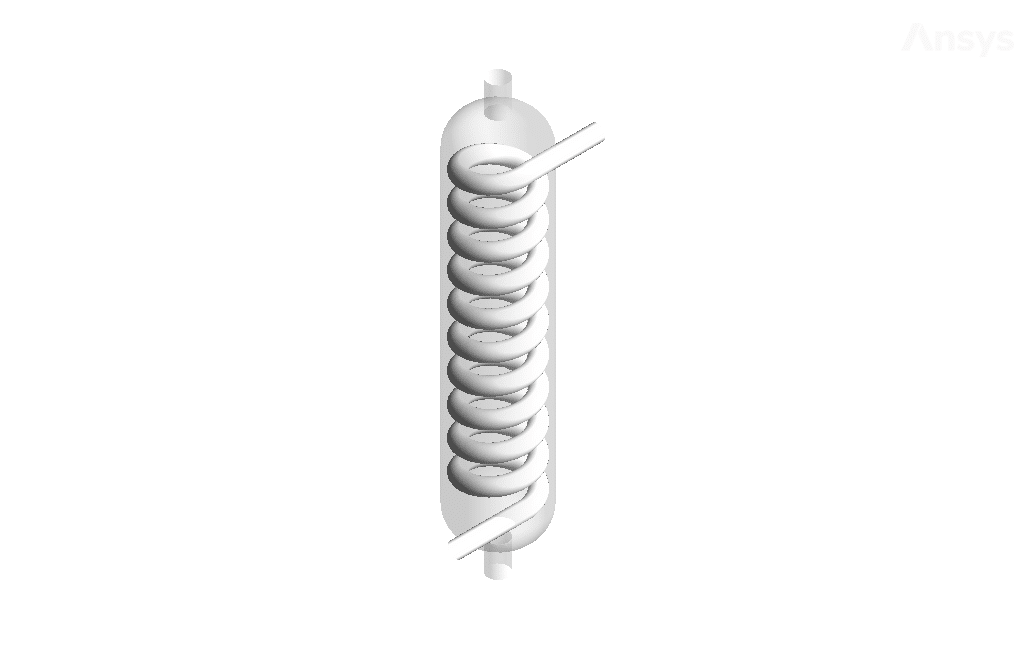

The present geometry is designed in a 3D model via Design Modeler. The computational zone is the interior space of a heat exchanger. This heat exchanger is shell and tube type; It consists of a vertical cylindrical shell with a spiral tube inside.

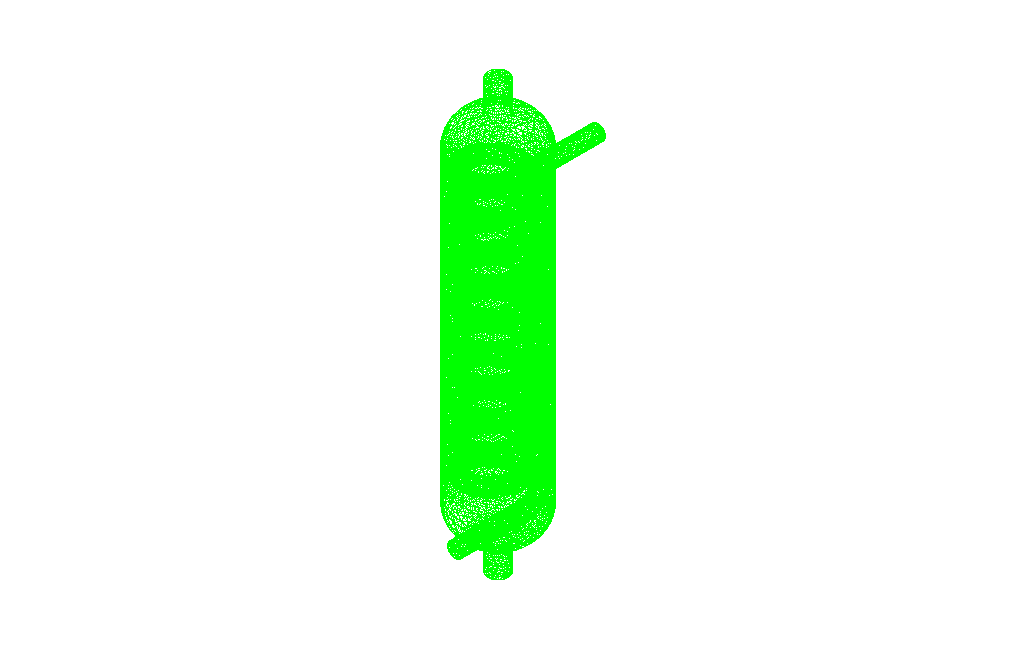

The mesh of the present model has been done via ANSYS Meshing. Mesh is done unstructured, and the number of production cells is equal to 640618.

Set-up & Solution

Assumptions used in this simulation :

- Pressure-based solver is used.

- The present simulation is steady.

- The effect of gravity is ignored.

| Models | ||

| Viscous | k-epsilon | |

| k-epsilon model | RNG | |

| Near-wall treatment | standard wall function | |

| Energy | On | |

| Boundary conditions | ||

| Inlet (shell) | Velocity Inlet | |

| velocity magnitude | 1.5 m.s-1 | |

| temperature | 400 K | |

| Inlet (tube) | Velocity Inlet | |

| velocity magnitude | 1.5 m.s-1 | |

| temperature | 900 C | |

| Walls (inner) | Wall | |

| wall motion | stationary wall | |

| thermal condition | coupled | |

| Walls (outer) | Wall | |

| wall motion | stationary wall | |

| heat flux | 0 W.m-2 | |

| Outlet (shell) | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Outlet (tube) | Pressure Outlet | |

| gauge pressure | 0 pascal | |

| Methods | ||

| Pressure-Velocity Coupling | coupled | |

| pressure | Second-order | |

| momentum | Second-order upwind | |

| energy | Second-order upwind | |

| turbulent kinetic energy | First-order upwind | |

| turbulent dissipation rate | First-order upwind | |

| Initialization | ||

| Initialization methods | hybrid | |

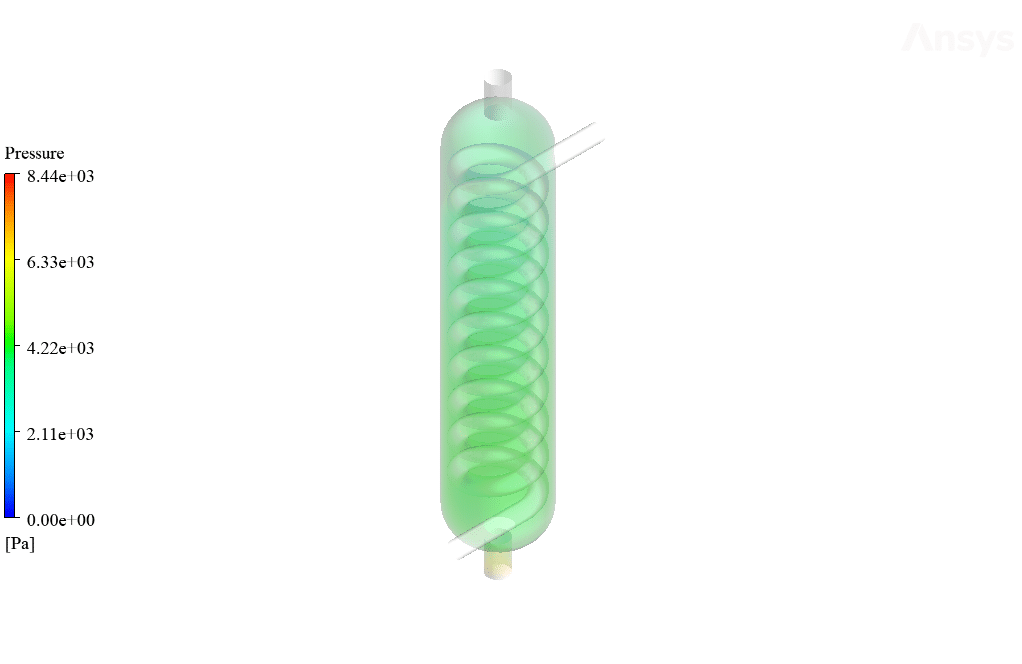

Vertical Heat Exchanger Results

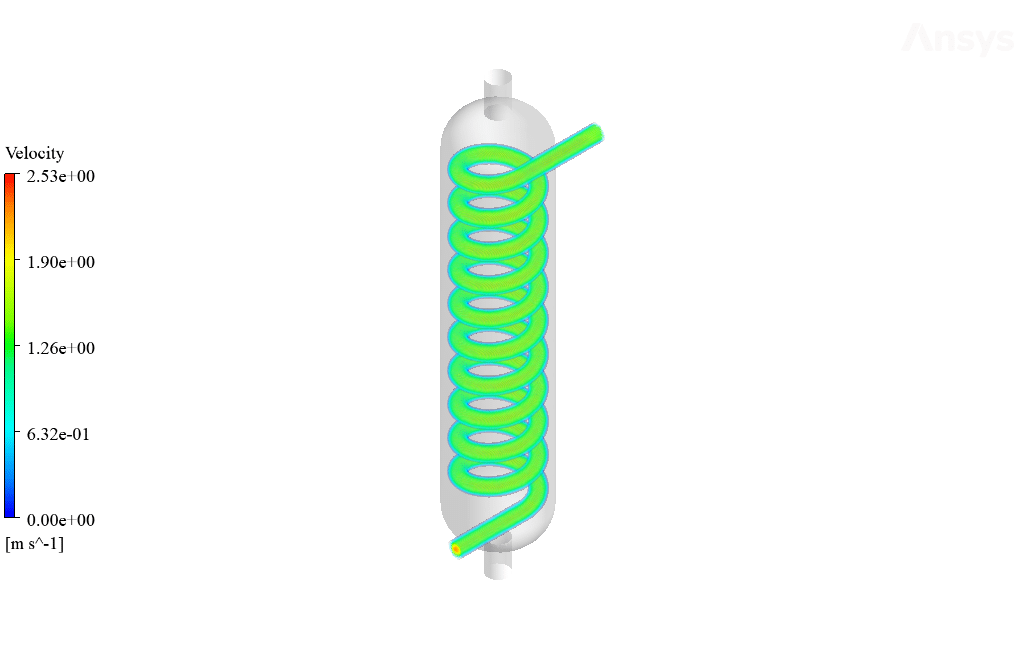

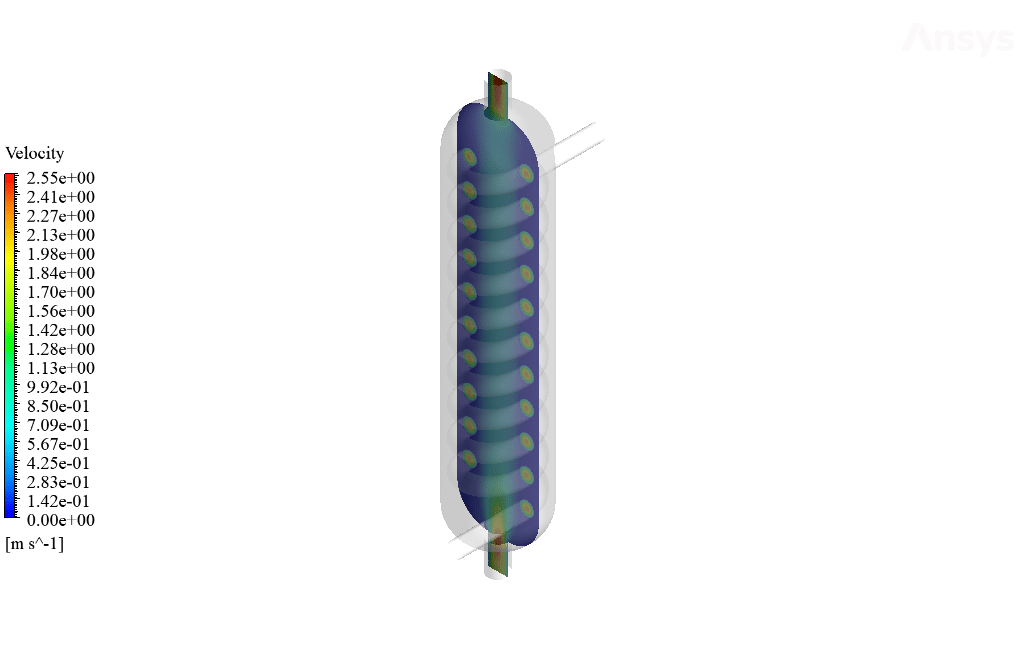

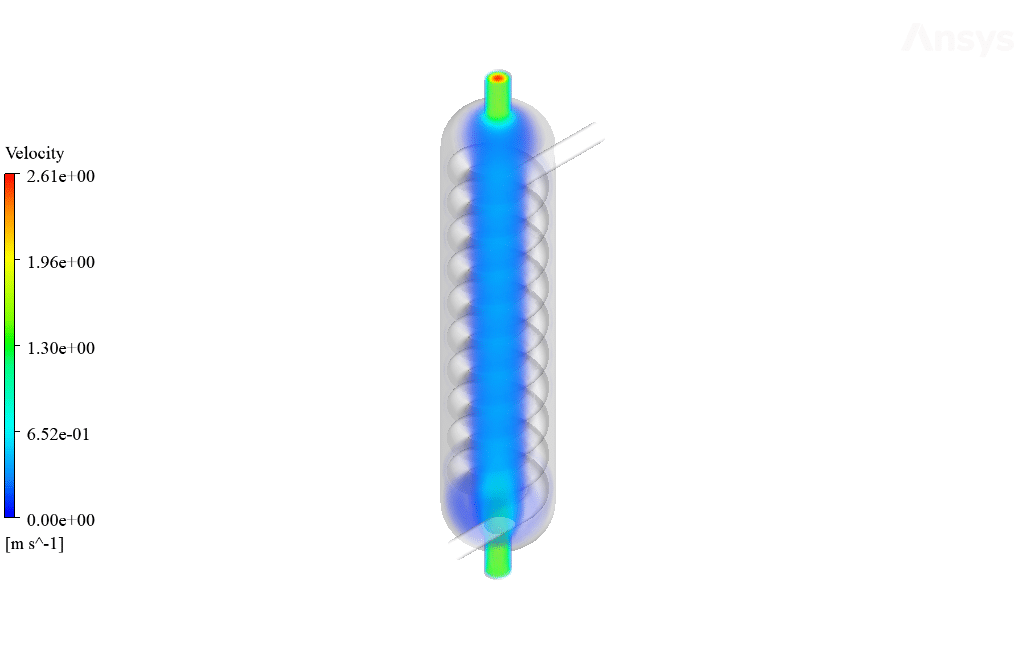

After calculation, 2D and 3D contours related to temperature, pressure, and velocity are obtained. The contours show that heat transfer occurs between the shell (with lower temperature) and the tube (with higher temperature). In this way, the liquid sodium flow inside the tube is cooled, and the liquid sodium flow inside the shell is heated.

Devante Schoen –

The Vertical shell and tube liquid sodium Heat Exchanger training was incredible! I could clearly grasp how heat exchange happens in industrial settings. The detailed explanation of sodium movement and temperature variations helped me in understanding the complexities of an actual process.

MR CFD Support –

Thank you for the kind words! We are thrilled to hear that the ANSYS Fluent CFD Simulation Training for the Vertical shell and tube Heat Exchanger with liquid sodium was clear and educational for you. It’s great to know that our training helped enhance your understanding of heat exchange processes in the industry. We appreciate your feedback!

Mr. Cade Stiedemann –

The results provided are very detailed! Could you shed some light on how the impact of heat transfer on liquid sodium’s velocity has been visualized in the simulation?

MR CFD Support –

We’re glad that you appreciated the level of detail! In the simulation, the impact of heat transfer on the liquid sodium’s velocity is visualized through velocity contour plots which display changes in velocity magnitude and direction within the heat exchanger. Due to the temperature-dependent properties of the liquid sodium, the density changes impact the velocity field as well. We show these effects around the cooling and heating sections to give a comprehensive understanding of the heat exchange process.

Roderick O’Hara –

I really appreciated the deep level of detail in explaining the complex heat exchange process with liquid sodium! The simulation setup mimics real-world applications, making it not just theoretically sound but also practically relevant.

MR CFD Support –

Thank you so much for the positive feedback! We’re thrilled to hear that our Vertical shell and tube liquid sodium Heat Exchanger training provided you with valuable insights and practical knowledge. We always strive to deliver detailed and relevant simulations. If you have further questions or need assistance in the future, feel free to reach out!

Lexie Bernier –

I’m thrilled with how the vertical heat exchanger simulation turned out, especially the liquid sodium flow which must be challenging to model due to its thermophysical properties varying with temperature. Well done MR CFD Company!

MR CFD Support –

Thank you so much for your kind words and recognition of our efforts! We’re glad to hear that you appreciated the complexity and accuracy of the liquid sodium flow simulation in the vertical heat exchanger. If you have any more questions or need further assistance, feel free to reach out!

Shanny Conn –

The vertical shell and tube liquid sodium heat exchanger simulation is incredibly detailed and shows a well-structured approach to thermal transfer. The clear definition of thermophysical properties varying with temperature along with the use of RNG k-epsilon model supplements the simulation’s precision. I’m impressed by the comprehensive modeling of geometry and meticulous meshing that leads to a substantial cell count for improved accuracy. Coupling both the inlet and outlet with appropriate temperature and pressure conditions illustrates a robust setup for evaluating performance in industrial conditions.

MR CFD Support –

Thank you for taking the time to review our Vertical shell and tube liquid sodium Heat Exchanger CFD Simulation Training. We are delighted to know that the level of detail in the simulation has met your expectations, offering a realistic and precise study of the heat exchanger’s performance. We appreciate your recognition of our accurate modeling and meshing efforts to provide a high-quality educational exercise using ANSYS Fluent. If there’s anything else you need to know about this simulation or any other product, feel free to ask.

Mr. Logan Nicolas Jr. –

I’m genuinely impressed by the detailed simulation of the vertical shell and tube liquid sodium heat exchanger in ANSYS Fluent! The explanation provided is comprehensive and showcases a complex thermal process with high-temperature differences. The choice of liquid sodium with properties varying by temperature makes the simulation particularly relevant for industrial applications. Great job on the meshing and set-up!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled that you found the simulation details comprehensive and relevant. Our team works diligently to ensure the accuracy and applicability of our CFD training materials for industrial scenarios. Your compliments are greatly appreciated, and we look forward to providing more high-quality simulations.

Gwendolyn Gorczany –

Really fascinating learning product! The level of detail and accuracy afforded by ANSYS Fluent in this simulation is incredible. The structured approach in design and meshing appears to meticulously capture the complexities of heat transfer in a shell and tube heat exchanger. Outstanding work by MR CFD in creating such an informative and educational simulation experience!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found our simulation training on heat transfer in a Vertical Shell and Tube Heat Exchanger to be detailed and informative. MR CFD takes pride in providing comprehensive learning materials to help our users understand complex CFD concepts effectively. Your positive feedback motivates us to continue delivering high-quality educational content.

Dr. Roosevelt Dibbert –

I cannot express how thrilled I am with the Vertical Shell and Tube Liquid Sodium Heat Exchanger simulation training! The level of detail and clarity in defining the process parameters and thermophysical properties had an enormous impact on my learning experience. The technical completion of the mesh with over 640k cells was instrumental for an accurate representation of sodium flows. And the results! The ability to visualize the heat transfer then and there – phenomenal. ANSYS Fluent, through this training, brilliantly showcased the synergy between various discrete parts and mechanisms of heat exchangers.

MR CFD Support –

We’re truly heartened by your positive feedback and glad to know our training product for the Vertical Shell and Tube Liquid Sodium Heat Exchanger simulation met your expectations so thoroughly! Seeing our customers succeed and benefit from detailed CFD simulations done in ANSYS Fluent is what drives us forward. We strive to ensure our training material is as informative and valuable as possible. If there’s anything else we can support your learning with, please don’t hesitate to let us know. Thank you for choosing MR CFD Company’s educational products!

Elmer McClure –

I just completed my study using the vertical shell and tube liquid sodium heat exchanger simulation as training. The results were so accurate and the detailed setup helped me fully understand each stage of heat transfer in the system. Really appreciated the RNG k-epsilon model being demonstrated as it was particularly relevant to my current thermodynamics project.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training has contributed significantly to your project and that our detailed simulation setup enhanced your understanding of heat transfer. It’s always our goal to provide accurate and useful resources for our customers, and we’re glad we could be of help to you.

Diana Abbott V –

I found the dynamic temperature-dependent properties of liquid sodium in this simulation intriguing. Do you have any tutorials or additional materials that could help understand the process for defining such temperature-dependent properties in ANSYS Fluent?

MR CFD Support –

Yes, we have dedicated training materials that cover the process of defining temperature-dependent properties of fluids like liquid sodium in ANSYS Fluent. Our tutorials guide you step by step, ensuring you understand how to input and manage variable properties for more accurate simulation results.

Ms. Fae Feil –

The learning product about the shell and tube liquid sodium heat exchanger is outstanding! The setup details were explained very well. It’s evident that comprehensive research and proper simulation design went into this tutorial. The clear description of boundary conditions and the solver settings provided a deep understanding. Coupled with the visualization of results through 2D and 3D contours, this training offers a great learning opportunity for understanding the intricacies of such a complex system.

MR CFD Support –

We are thrilled to hear that you’re satisfied with the vertical shell and tube liquid sodium heat exchanger simulation training. Thank you for your acknowledgment of the comprehensive research and detailed tutorial. We put a lot of effort into ensuring the accuracy and clarity of our simulations to facilitate the best learning experience. Your appreciation of the setup details and visual aids is highly motivating. If you have any more feedback or require further assistance, feel free to reach out to us!

Mr. Rickey VonRueden II –

I am absolutely impressed by how thorough and detailed this training is! The simulation catered to all the complexities of modeling a heat exchanger and even included the unique properties of liquid sodium. A truly comprehensive learning tool.

MR CFD Support –

Thank you for your kind words! We’re thrilled that you found our training to be comprehensive and valuable. If you have any further interests or need assistance with similar simulations, remember we’re here to support your learning journey!

Clementine Lockman –

This training module on liquid sodium heat exchangers sounds incredibly informative! The details on setup and operation seem well-explained and comprehensive. Understanding the complexities of temperature-dependent material properties in fluid dynamics can be quite challenging, and it seems like this course would provide valuable insights into that area.

MR CFD Support –

Thank you for the positive feedback on our vertical shell and tube heat exchanger CFD simulation training featuring liquid sodium as the working fluid. We’re delighted to hear that you found the training module informative and comprehensive; your satisfaction is our top priority. Do not hesitate to reach out if you need any further understanding or have other topics you’re interested in learning about.

Prof. Valentina Walter II –

This vertical shell and tube heat exchanger simulation is incredibly detailed. Its capability to manage temperature-dependent properties of liquid sodium really stands out. This feature is crucial for the application in high-temperature scenarios like nuclear reactors. Well-crafted geometry and comprehensive results lend further credence to the effectiveness of this training material in acquainting users with CFD applications in energy systems. Kudos to the MR CFD Company for devising such an intricate and applicable simulation tutorial.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that you’ve found the details and applications of the vertical shell and tube heat exchanger simulation to be valuable and relevant to high-temperature industrial setups. We genuinely appreciate your kind words about the simulation’s craftsmanship and the tutorial’s ability to educate on CFD in energy systems. Your encouragement inspires us to continue creating high-quality and comprehensive learning materials!

Mr. Justice Turcotte I –

I just finished the simulation training for the vertical shell and tube liquid sodium heat exchanger using Ansys Fluent. Given the complexity of this subject, I was pleasantly surprised at how well it was explained. The setup instructions were clear, the meshing was perfectly understandable, and seeing the effects of the temperature change on the thermophysical properties of the liquid sodium was fascinating.

MR CFD Support –

We’re thrilled to hear that our simulation training for the vertical shell and tube liquid sodium heat exchanger met your expectations! It’s rewarding to know that our efforts to create clear and comprehensive instructions contributed to your positive learning experience. Your insights regarding the temperature effect on liquid sodium’s properties showcase the depth of your understanding. Thank you for your kind words, and we’re grateful for your feedback!

Oral Schmitt –

What an outstanding way to visualize heat transfer processes in industries! The clarity in understanding the heat exchange between the shell and tube sides using liquid sodium in ANSYS Fluent is definitely a leap forward in simulation training.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our simulation training on vertical shell and tube liquid sodium heat exchangers was clear and educational. If you’re interested in advancing your knowledge further or have any questions, we’re here to help!

Sean Hodkiewicz DVM –

This training material was very detailed and helpful for gaining practical experience with heat exchangers using liquid sodium. The setup and boundary conditions explanations were especially insightful. The results conveyed through the 2D and 3D contours solidified my understanding of the conductive and convective heat transfer processes within the system.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to know that our training material on the vertical shell and tube heat exchanger using liquid sodium was helpful and that the explanations of setup, boundary conditions as well as the 2D and 3D contour results contributed to your understanding. If you have any further questions or need additional clarifications, please do not hesitate to ask. Your learning and satisfaction are our top priorities.

Dr. Efrain Bartell MD –

Wow, I saw the contours illustrating the heat transfer in your report and they’re very detailed. Especially how the liquid sodium behaves within the shell and tube design—it really clarifies the effectiveness of the heat exchanger’s design!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our simulations and the resulting visualizations have helped deepen your understanding of the heat exchanger’s functionality. It’s great that the details in the contours were clear and informative. Feel free to reach out if you have any more questions or need further clarification.

Antwon Hoppe –

I was really impressed with the results of the liquid sodium heat exchanger simulation. Great to see how effectively the simulation demonstrated the heat transfer process!

MR CFD Support –

We appreciate your kind words and are thrilled that you found the simulation results impressive. Seeing the heat transfer process visualized accurately in the simulation reaffirms the reliability and quality of our training material. Thank you for taking the time to provide your feedback!

Vivien Cummerata –

The demonstration of heat transfer between the low-temperature shell and the high-temperature tube is indeed fascinating. The detailed setup shows thorough work incorporating thermophysical properties variations, lending great value to those learning about complex heat exchangers in industries like nuclear power where liquid sodium is used. Great job outlining the flow dynamics and temperature changes throughout the system.

MR CFD Support –

Thank you very much for your positive feedback! We’re glad that the detailed simulation setup and the results were able to convey the complex heat transfer processes in such heat exchangers. We are thrilled that you found it to be thorough and valuable for understanding the industrial applications of CFD in liquid sodium heat exchangers. If you have any further questions or need more information on similar simulations, feel free to reach out to us.

Bridgette O’Hara –

I’m thoroughly impressed with how the CFD simulation captures liquid sodium flow dynamics. The detailed observation of temperature, pressure, and velocity changes through unstructured meshing is commendable. The immersion into the heat exchange process from a training perspective is invaluable. Well done!

MR CFD Support –

Thank you so much for your positive feedback. We always strive to provide detailed and accurate simulations to facilitate a deep understanding of complex fluid dynamics and heat exchange processes. It’s wonderful to hear that our efforts to create an immersive learning experience are appreciated. If you ever have any questions or need further assistance in understanding any aspect of our training materials, please don’t hesitate to reach out!

Lauretta Sporer II –

Fantastic training platform! As someone who has always been intimidated by CFD simulations, this Vertical shell and tube liquid sodium Heat Exchanger course made the process digestible and even enjoyable. The structured approach, clear explanations, and practical assignments provided me with the tools I need to apply these practices to real-world problems. Kudos to the MR CFD team for demystifying the complexity of ANSYS Fluent!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Vertical shell and tube liquid sodium Heat Exchanger training has been helpful to you. At MR CFD, we aim to simplify complex concepts and ensure our customers feel confident applying what they’ve learned. We appreciate your review and are here to support your continued learning journey in CFD simulations!

Dr. Ariel Schuster –

This was exactly what I was looking for, providing clarity on heat exchanger simulations using liquid sodium. Fantastic learning experience, with precise detail on setup and boundary conditions.

MR CFD Support –

Thank you for your positive review! We are thrilled to hear that our training on the vertical shell and tube liquid sodium heat exchanger using ANSYS Fluent met your expectations and provided you with the clarity and details you needed. If there’s anything more you would like to learn or if you need further assistance, don’t hesitate to reach out. We’re here to support your continued learning journey!

Ms. Whitney Graham –

This was an impressive course on vertical shell and tube heat exchanger simulation with liquid sodium. I didn’t just gain insight into the behavior of liquid sodium in such systems but also became proficient in setting up and running a steady-state CFD simulation in ANSYS Fluent. Versatile knowledge on various ANSYS tools, unique boundary conditions, and result interpretation techniques were truly beneficial. Well-structured and packed with valuable tips & tricks for handling complex heat transfer analysis!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to know that our course on vertical shell and tube heat exchanger simulation met your expectations and enhanced your skills in CFD analysis using ANSYS Fluent. It’s wonderful to hear that you found the content comprehensive and the instructional material effective. Should you have any further inquiries or need assistance in future projects, don’t hesitate to reach out. Your success is our goal at MR CFD, and we appreciate you choosing our learning products.