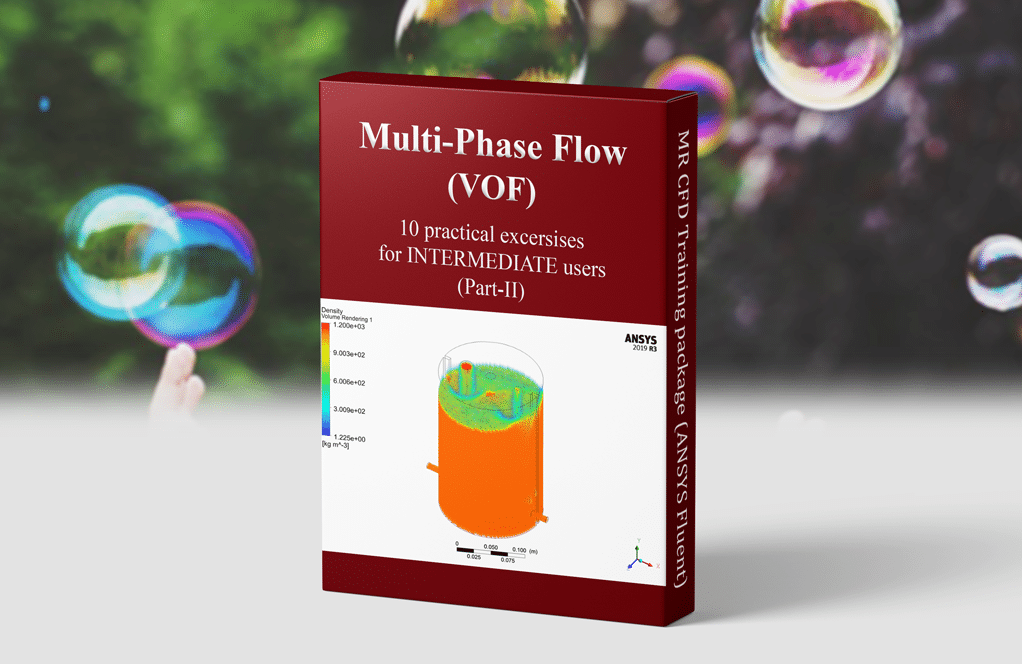

Volume of Fluid (VOF), Package for Intermediate, Part 2, 10 Learning Products

$299.00 $149.50 Student Discount

This CFD training package is prepared for intermediate users of Ansys Fluent software in the Volume of Fluid (VOF) Multiphase area.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Multi-phase Volume Of Fluid (VOF) – ANSYS Fluent Training Package, 10 Practical Exercises for INTERMEDIATE Users

This CFD training package is prepared for intermediate users of Ansys Fluent software in the Volume of Fluid (VOF) Multiphase area. You will learn and obtain comprehensive training on how to simulate medium projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

This package trains the necessary proficiency you will require to start doing average computational fluid dynamics (CFD) Multi-phase VOF simulations on your own using Ansys Fluent software. Qualified training movies and comprehensive CFD concepts explanations, including setup, solution, results, and all perspectives of carrying out CFD simulations in Ansys Fluent.

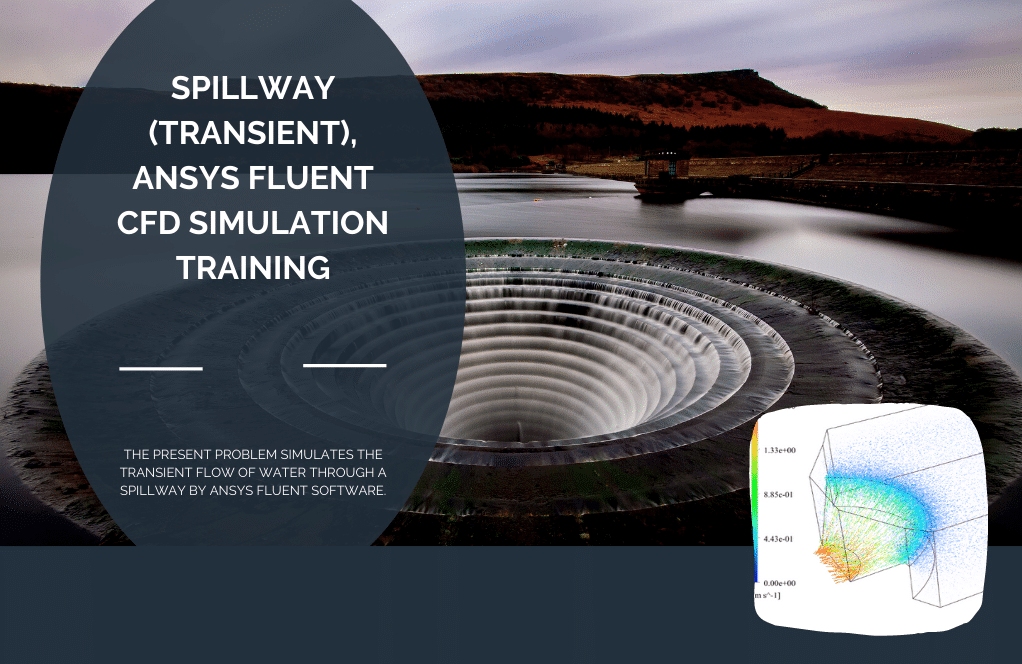

Civil Structures

Spillways are structures used to pass through excess water and floods from the top to the bottom of the dam. In fact, spillways are structures with a certain height that discharge excess water when the water’s height exceeds its height. Project number 1 simulates the flow of water through a spillway. Since the modeled fluids are water and air, the two-phase flow model is used. To define the two-phase flow in this simulation, a two-phase VOF (volume of fluid) model is used.

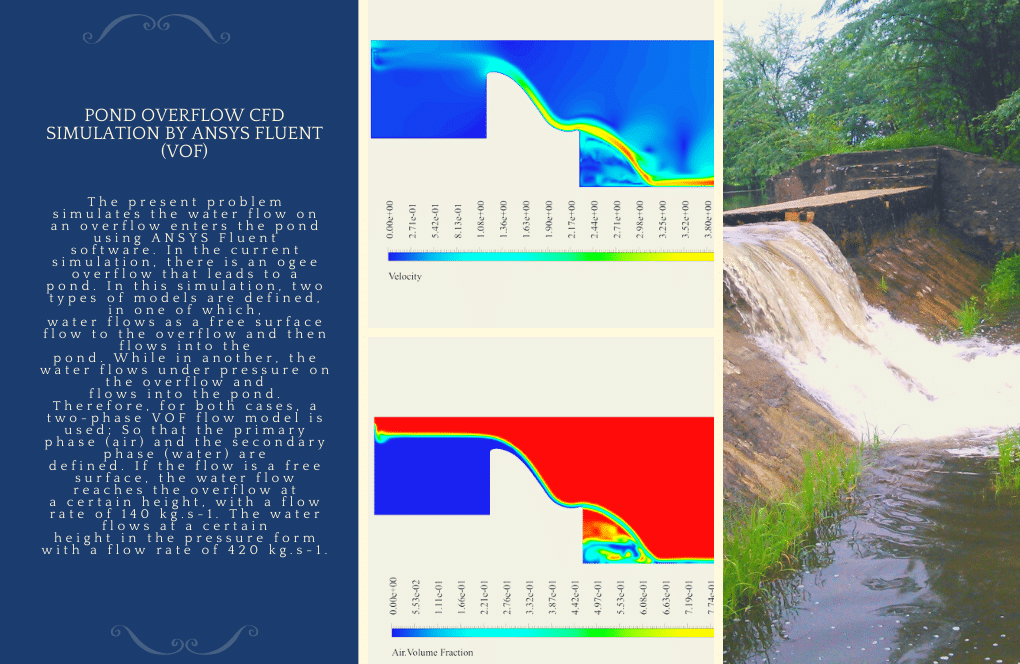

Project number 2 simulates the water flow on an overflow that enters the pond. There is an ogee overflow in the current simulation that leads to a pond. In this simulation, two types of models are defined, in one of which, water flows as a free surface flow to the overflow and then flows into the pond; While in another, the water flows under pressure on the overflow and flows into the pond. Therefore, for both cases, a two-phase VOF flow model is used; So that the primary phase (air) and the second phase (water) are defined.

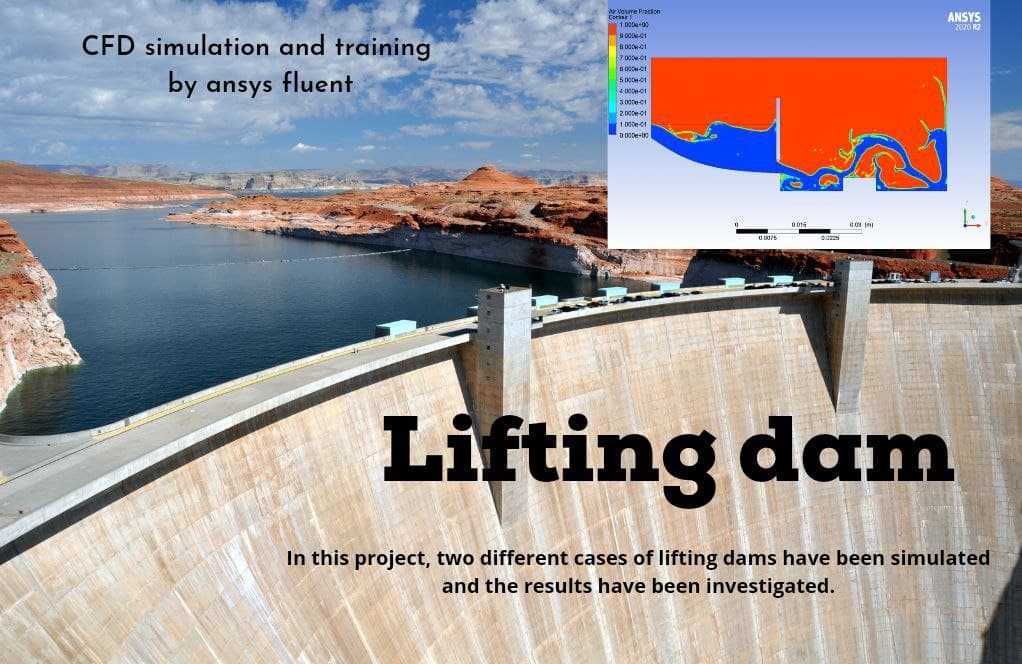

In project number 3, a Numerical simulation of the lifting dam has been performed. The VOF model is used to simulate two fluid phases, and the purpose of this project is to investigate the changes in the free surface of the fluid over time. Two models are reviewed in this project. In the first model, the flow continues its path after crossing the dam, but in the second model, it encounters an obstacle.

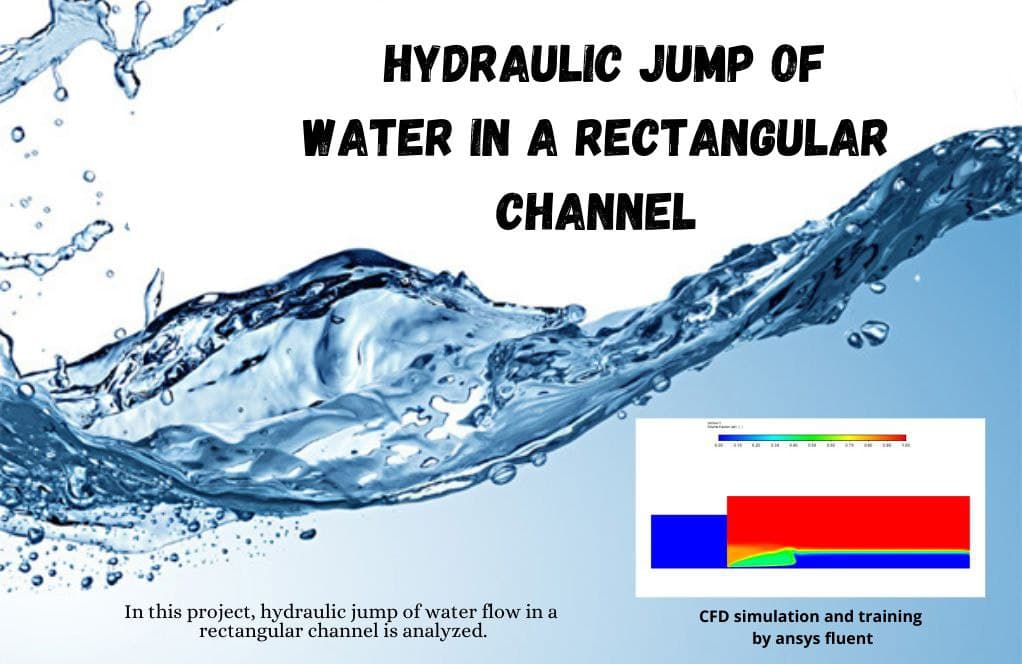

In project number 4, the hydraulic jump of water flow is analyzed. The VOF approach is utilized to simulate the water flow inside ambient air efficiently. Hydraulic jump is of great importance in agricultural applications and open channel flows where water flow, after a certain distance which can be solved using the analytical equation, undergoes a significant decrease in velocity and increase in flow height. The present work analyzes water flow with two different mass flow inlets, 50 and 80 kg/s.

Separator (volume of fluid)

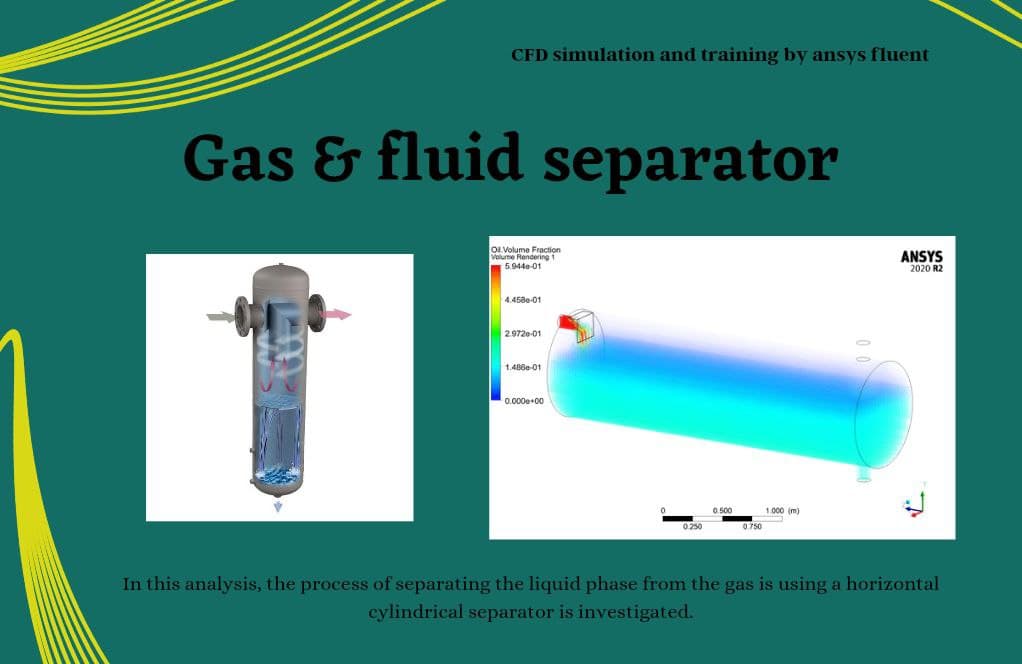

In project number 5, separating the liquid phase from the gas using a horizontal cylindrical separator is investigated. A multi-phase VOF model is activated to simulate two phases of oil and hydrogen sulfide inside the separator. The mixture of oil and gas (with mass flow rates of 3kg/s and 0.15kg/s, respectively) enters the separator and since the oil is heavier than the gas, it settles down while the gas phase exits from the top outlet

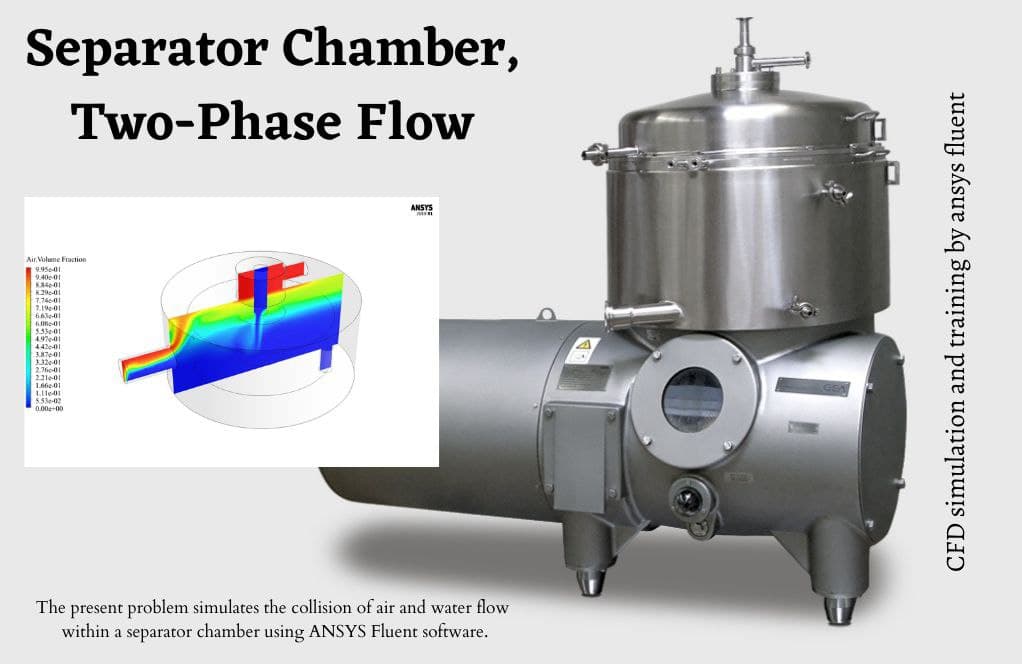

Project number 6 simulates the collision of air and water flow within a separator chamber. In this model, a cylindrical separator chamber is designed whose interior space is full of water. Since this modeling has two phases, the multi-phase model should be used. For this reason, the VOF multiphase model is used in this modeling also, the effect of surface tension between the two phases is defined and the amount of surface tension between the two phases of the water and air is defined as 0.072 N.m-1.

Mixer

In project number 7, a mixer tank is modeled, and the effect of its rotating impeller on the mixing procedure is investigated. The simulation uses the VOF model for the three phases of air, water, and salt. The k-epsilon model is applied for solving the turbulent flow inside the tank. MRF model is also used to model the rotation of the impeller.

Distillation

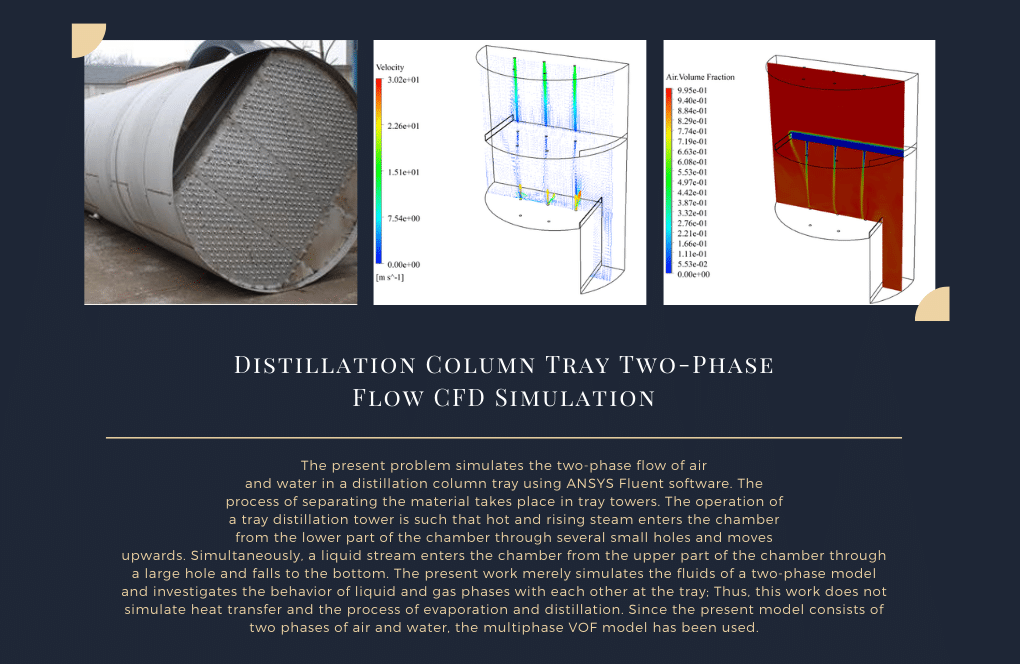

Project number 8 simulates the two-phase flow of air and water in a distillation column tray. In tray towers, the process of separating the material takes place. His work does not simulate heat transfer and the process of evaporation and distillation. Since the present model consists of two phases of air and water, the multi-phase VOF model has been used.

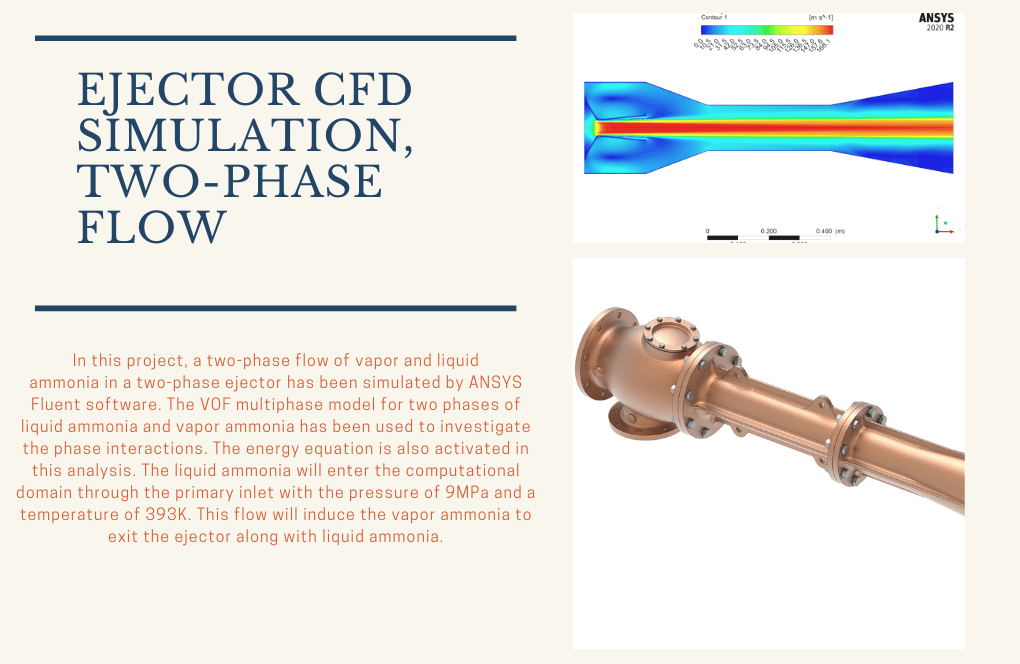

Ejector (volume of fluid)

In project number 9, the two-phase flow of vapor and liquid ammonia in a two-phase ejector has been simulated. The VOF multi-phase model for two phases of liquid ammonia and vapor ammonia has been used to investigate the phase interactions. The liquid ammonia will enter the computational domain through the primary inlet with a pressure of 9MPa and a temperature of 393K. This flow will induce the vapor ammonia to exit the ejector and liquid ammonia.

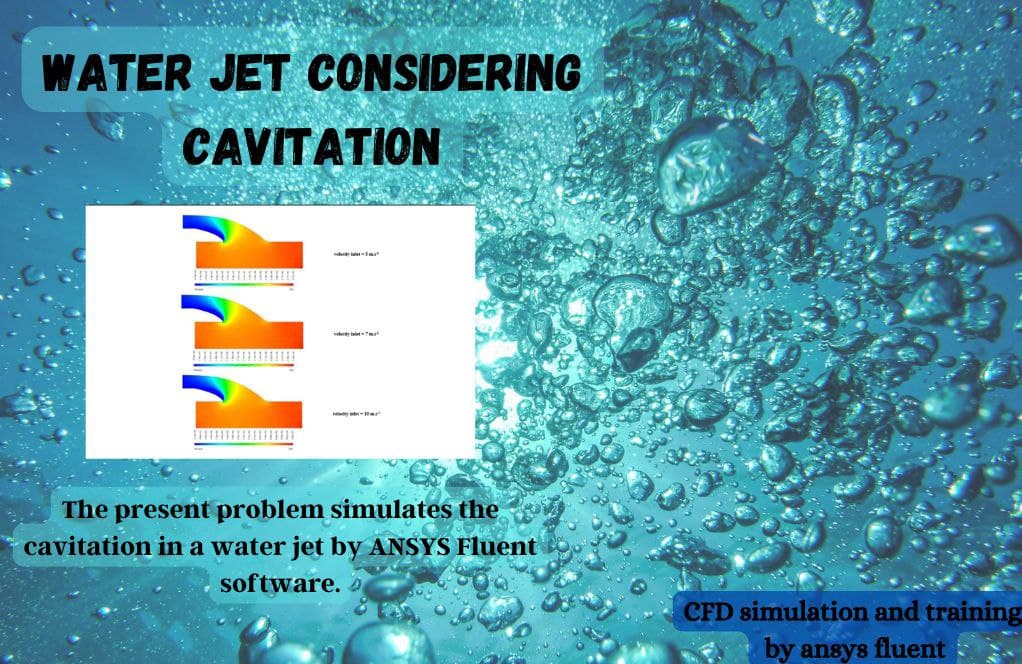

Cavitation

Project number 10 simulates the water flow in a water jet. Since there is a possibility of pressure drop in this model, the cavitation phenomenon has been investigated because this phenomenon occurs when the fluid pressure drops to its vapor pressure. Therefore, the model of two-phase VOF flow and mass transfer between two phases of water and water vapor is defined as cavitation at a vapor pressure equal to 3540 Pascal. The present work aims to investigate the changes in the volume fraction of water and water vapor phases.

Dr. Rita Metz –

The VOF Training Package is truly comprehensive and enlightening. The step by step tutorials, paired with qualified training movies, have provided a clear understanding of both the setup and outcomes of each simulation. The methodology is meticulous and offers deep insights into complex multi-phase simulations. Particularly impressive is the range of applications, from civil structures to separators and mixers, each increasingly beneficial with your expert guidance. Kudos to MR CFD for delivering knowledge in such an accessible and practical way; I look forward to utilizing these skills in my own CFD projects.

MR CFD Support –

Thank you for your positive feedback on our Volume of Fluid (VOF) Intermediate Training Package. We are thrilled to hear that you’ve found it comprehensive and enlightening. It is great to know that our tutorials and training materials have aided in your understanding of multi-phase simulations in Ansys Fluent. Your excitement about applying these skills to your projects motivates us to continue providing high-quality learning resources. If you have any questions or need further assistance as you embark on your CFD journey, do not hesitate to reach out. We wish you success in all your future CFD endeavors!

Dulce Schamberger –

I’ve completed the intermediate VOF training package and feel confident to start my own simulations! The hands-on exercises were incredibly valuable.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our intermediate VOF training package has effectively prepared you for your own CFD simulations. Best of luck with your projects, and should you have any questions in the future, feel free to reach out to us.

Jammie O’Connell –

I’ve just completed the ‘Volume of Fluid (VOF), Package for Intermediate, Part 2’ from MR CFD, and it was a fantastic learning experience. The ten distinct projects allowed me to delve deeply into multi-phase simulations using VOF and gave me the confidence to tackle real-world CFD challenges. The balance between theoretical knowledge and practical skills is commendable, providing a strong foundation for anyone looking to excel in the flow analysis of civil structures like spillways, separators, and even complex mixer tanks. Thanks, MR CFD, for such a thorough and enjoyable educational journey!

MR CFD Support –

We’re thrilled to hear you found the Volume of Fluid (VOF) package so enriching and balanced! It’s always rewarding to learn that our customers can confidently apply the skills and knowledge acquired from our products to solve complex CFD problems. Thank you for choosing MR CFD and for taking the time to share your positive experience. Your feedback is greatly appreciated! If you have any additional inquiries or need further assistance with your simulations, feel free to reach out to us.

Prof. Broderick Batz PhD –

I am curious, in Project number 4, how is the hydraulic jump analyzed in scenarios with two different mass flow inlets effectively?

MR CFD Support –

In Project number 4, the hydraulic jump is analyzed by simulating both scenarios with respective mass flow inlets of 50 kg/s and 80 kg/s using the VOF approach. The simulations would capture how the water interacts with the ambient air, determining the location and characteristics of the hydraulic jump for each flow rate, therefore enabling us to evaluate the effects of varying inflows on the hydraulic jump phenomenon.

Clemmie Ortiz –

I have gone through the VOF Training Package for Intermediate users, and I find the simulations quite comprehensive and detailed. In simulation number 6 involving the water and air collision in the separator chamber, I wonder how effectively it models real-world scenarios?

MR CFD Support –

The simulation involving water and air collision in separator chamber models real-world scenarios quite effectively by utilizing the VOF multiphase model and taking into account realistic factors such as surface tension between the phases. The conditions are set up to mimic the interaction dynamics and behavior that would occur in similar physical setups, providing valuable insights into the physical phenomena at play.

Prof. Carlos Schinner Jr. –

I’ve been going through Project 6 regarding the air and water flow collision in a separator chamber and I’m eager to know if in your simulation you’ve implemented any gravity effects or is the separation only due to difference in density and surface tension?

MR CFD Support –

In our simulation for Project 6, gravity effects are indeed taken into account to more accurately model the separation process within the cylindrical separator chamber. While the density difference and surface tension play significant roles, gravity is included to ensure that the buoyancy effects lead to natural segregation of the water and air, akin to a real-world scenario.