Water Tank Filling Process With Time Step Size Control UDF, CFD Simulation

$240.00 $120.00 Student Discount

- This study uses CFD simulation to investigate the water tank filling process

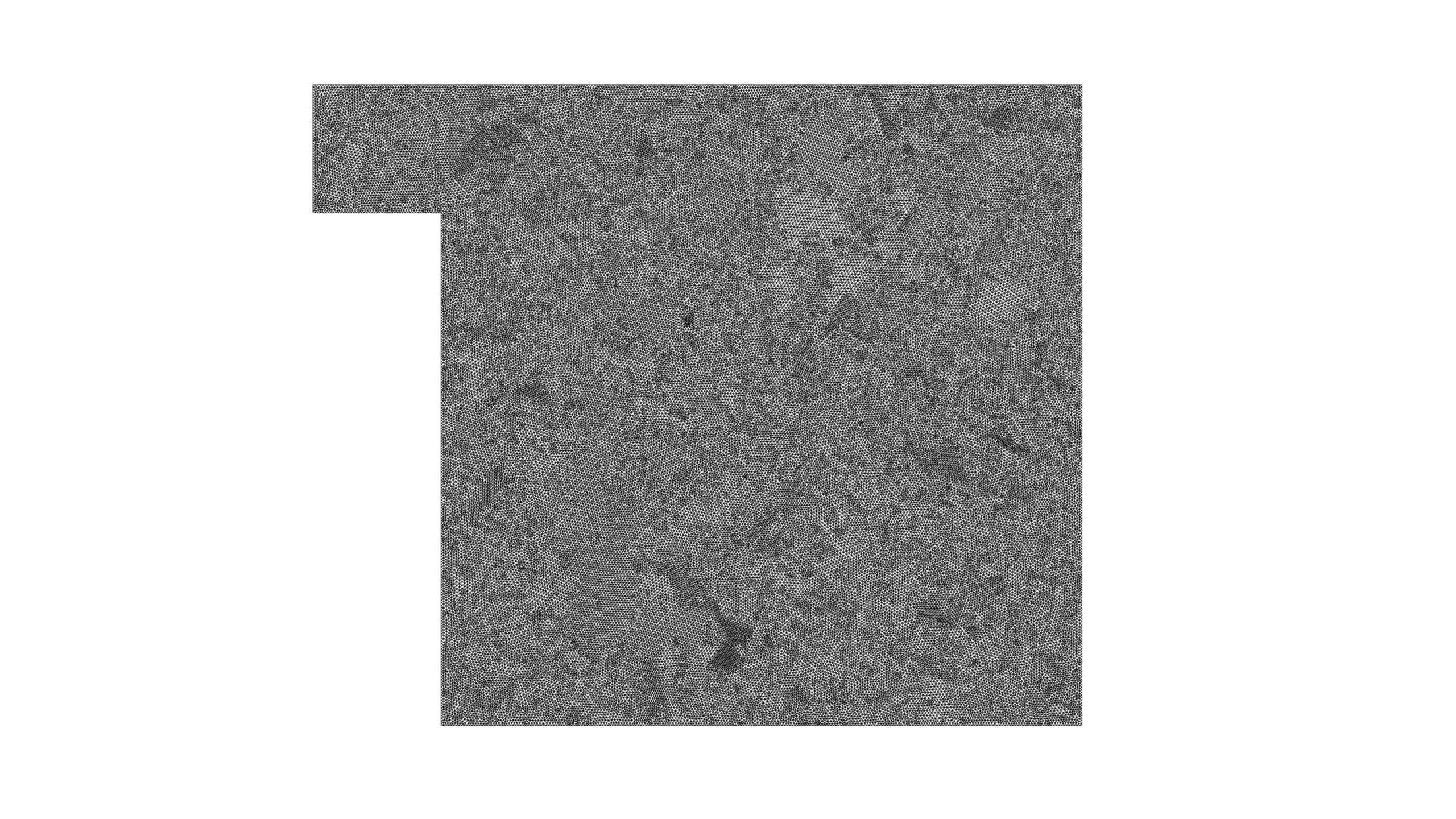

- The geometry of the tank was created using ANSYS Design Modeler, and the computational domain was discretized using ANSYS Meshing, resulting in over 135,000 elements

- The Volume of Fluid (VOF) model was employed to simulate the interaction between water and air phases

- A User-Defined Function (UDF) was implemented to control the time step size

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction

This study uses computational fluid dynamics (CFD) simulation to investigate the water tank filling process. Understanding the dynamics of Water Tank Filling is crucial for various industrial applications, including water storage, chemical processing, and hydraulic systems. The simulation aims to visualize and analyze the water flow patterns, air displacement, and interface behavior during the filling process.

The simulation was conducted using ANSYS Fluent, a powerful CFD software package. The geometry of the Water Tank was created using ANSYS Design Modeler, and the computational domain was discretized using ANSYS Meshing, resulting in over 135,000 elements, providing a balance between computational efficiency and solution accuracy.

Methodology

A pressure-based solver was used in a transient state, allowing for time-dependent analysis of the filling process.

The Realizable k-epsilon model with standard wall function was selected to capture the complex flow patterns during filling.

The Volume of Fluid (VOF) model with implicit formulation was employed to simulate the interaction between water and air phases.

A User-Defined Function (UDF) was implemented to control the time step size, enhancing simulation stability and accuracy.

Enabled in the y-direction to accurately model the gravitational effects on the fluid.

Results

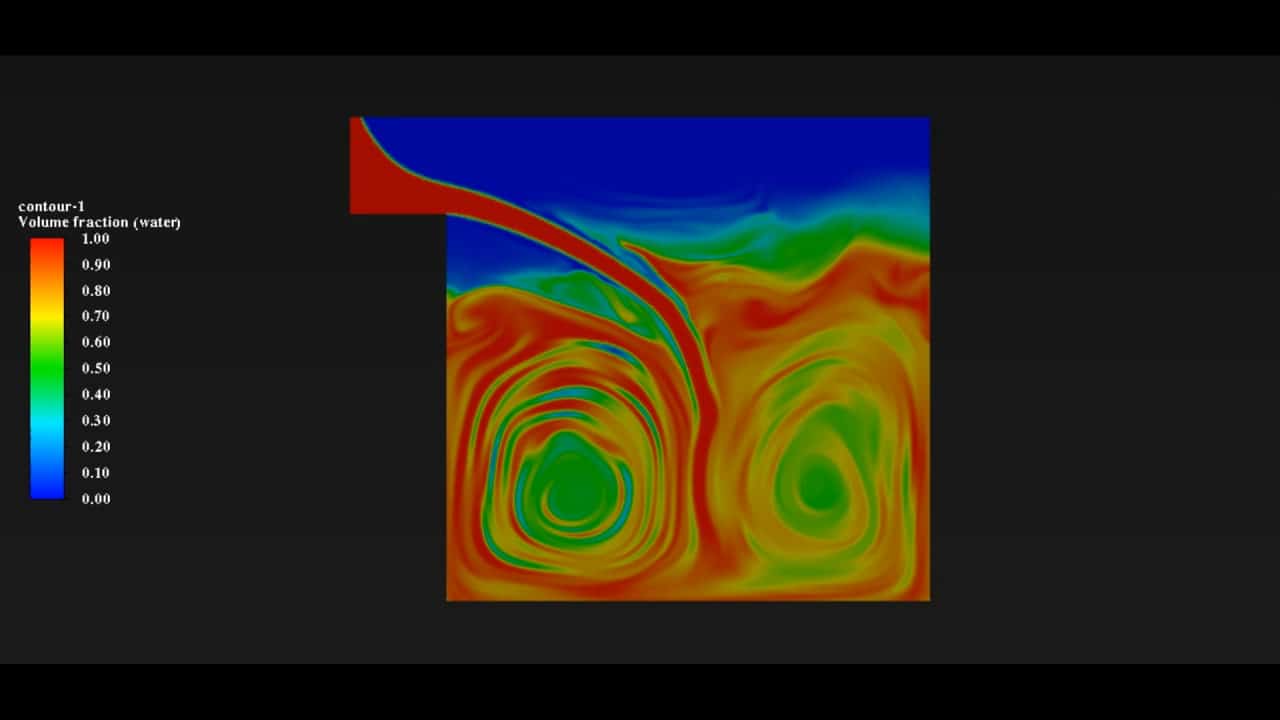

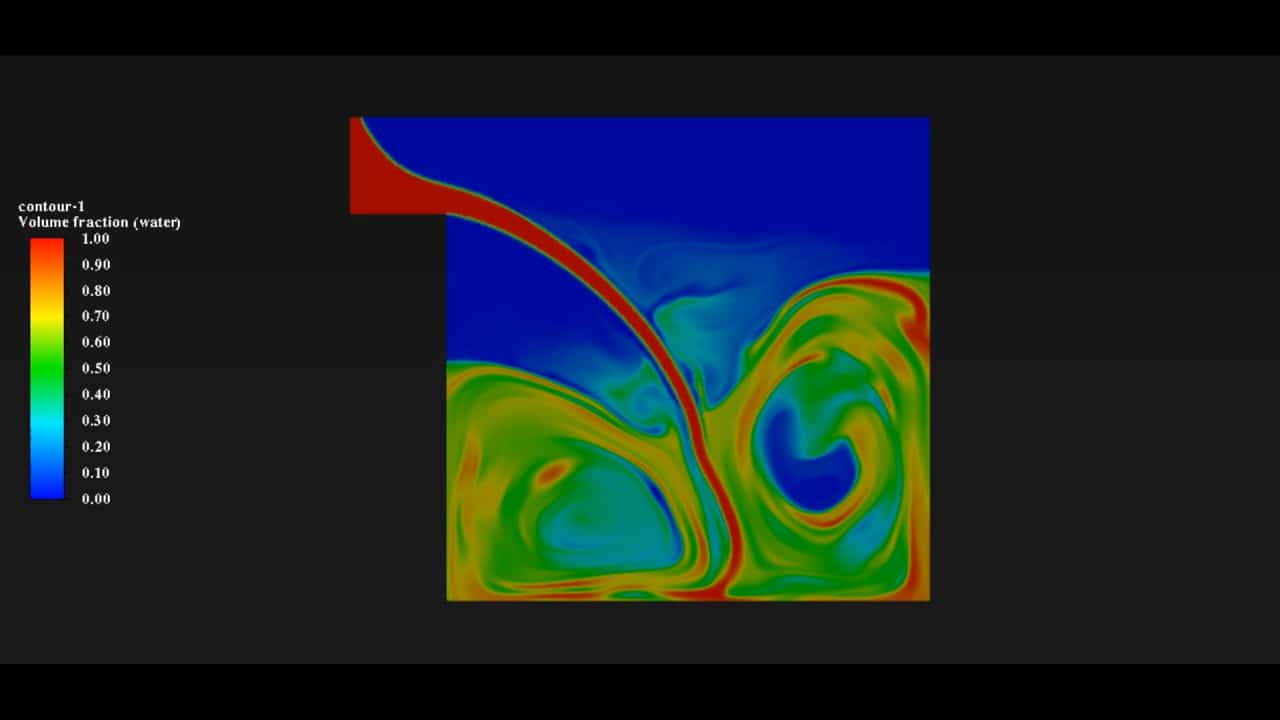

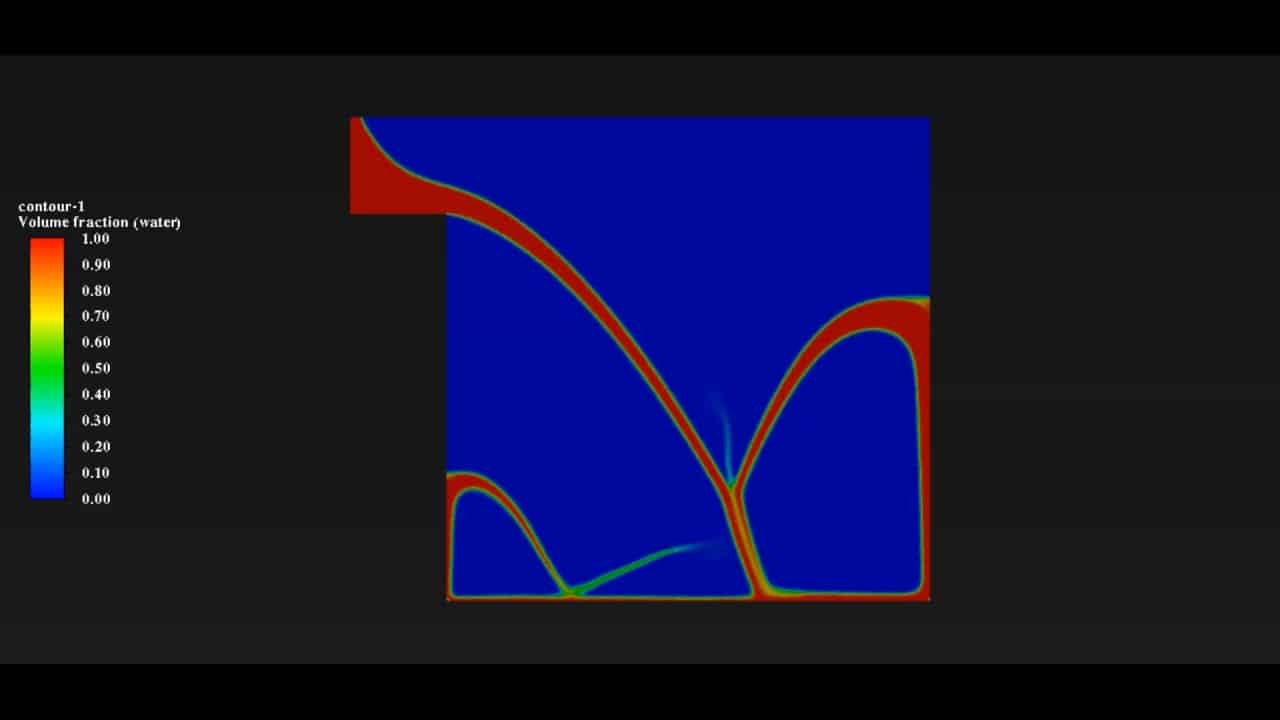

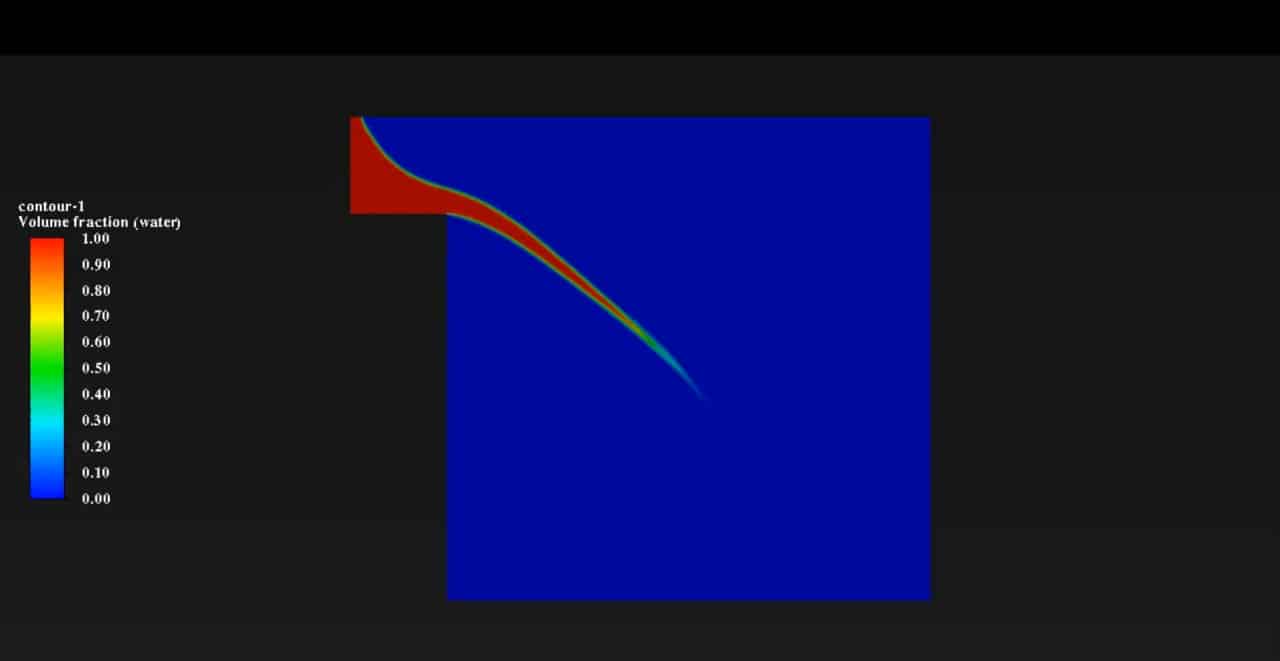

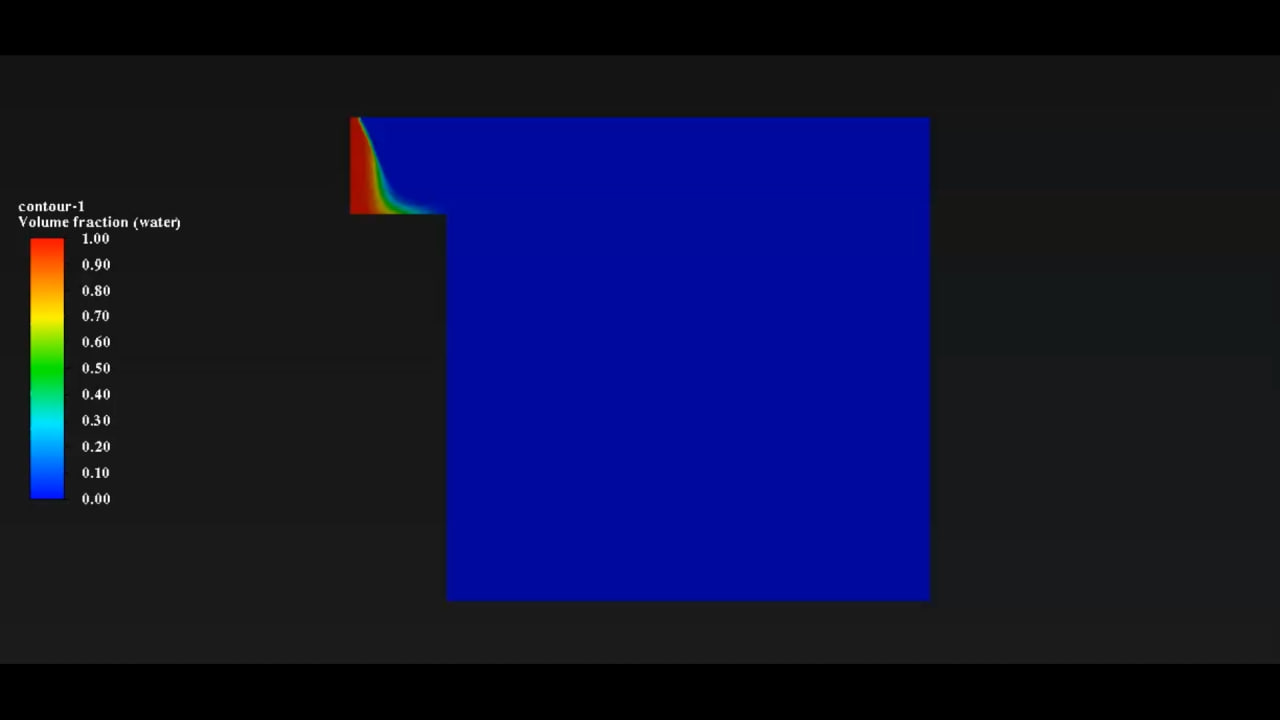

The CFD simulation successfully captured the complex dynamics of Water Tank filling . The animation reveals the progressive filling process, starting with water entering from the top left corner of the tank. As the simulation advances, a distinct interface between water (red) and air (blue) forms, demonstrating the capabilities of the Volume of Fluid (VOF) model in capturing multiphase interactions.

The water jet creates turbulent structures as it impacts the growing water body, showcasing the effectiveness of the Realizable k-epsilon turbulence model. Complex flow patterns emerge, including vortices and air pockets, particularly visible in the later stages of filling. The gradual displacement of air by water is evident, with the interface evolving from a simple curve to more intricate shapes as the tank fills.

The UDF-controlled time step allows for accurate capture of both rapid changes in the early stages and more gradual changes as the tank fills. The simulation provides valuable insights into the filling process, including the formation of eddies, potential air entrapment, and the overall fluid behavior. These results can be instrumental in optimizing tank design and filling strategies for various industrial applications.

Reviews

There are no reviews yet.