Wire Mesh Demister (DDPM), Paper Numerical Validation, ANSYS Fluent CFD Training

$320.00 $160.00 Student Discount

The present problem simulates the flow of water vapor passing through a demister containing saline water droplets using ANSYS Fluent software. This simulation is based on the information of a reference article “Eulerian–Lagrangian modeling and computational fluid dynamics simulation of wire mesh demisters in MSF plants,” and its results are compared and validated with the results in the article.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Paper Description

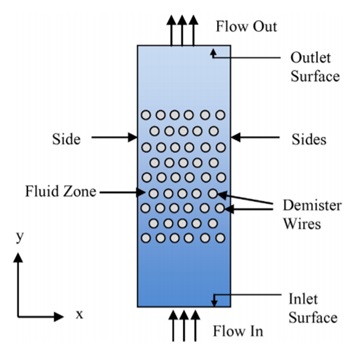

The present problem simulates the flow of water vapor passing through a demister containing saline water droplets using ANSYS Fluent software. This simulation is based on the information from a reference article, “Eulerian–Lagrangian modeling and computational fluid dynamics simulation of wire mesh demisters in MSF plants,” Its results are compared and validated with the results in the article. This demister is related to a multistage flash (MSF) desalination system. This demister consists of a metal wire mesh set responsible for separating the saltwater droplets in the water vapor stream. Therefore, to define the flow in this modeling, it is necessary to define a multiphase flow model.

In the present simulation, the Eulerian-Lagrangian perspective on computational fluid dynamics (CFD) is used; So that the Eulerian multiphase model is coupled with the dense discrete phase model (DDPM). So a continuous phase is defined, which is related to water vapor, and a discrete phase is defined, related to salt water droplets. Water vapor enters from the bottom of the system along with discrete droplets of salt water and exits the top after passing through the metal wire mesh. This work aims to investigate the amount of pressure drop due to the passage of flow through these wire mesh. Water vapor enters the system with a temperature of 373.15 K and a speed of 2-4 m.s-1.

Paper Description

The saltwater droplets have a density equal to 1300 kg.m-3 and a specific heat capacity equal to 3900 j.kg-1.K-1 and have a diameter equal to 0.00001 m and a temperature equal to 373.15 K and a velocity equal to With 2-4 ms-1 and mass flow equal to 1 * e-50 kg.s-1 enter from the bottom of the system.

Wire Mesh Geometry & Mesh

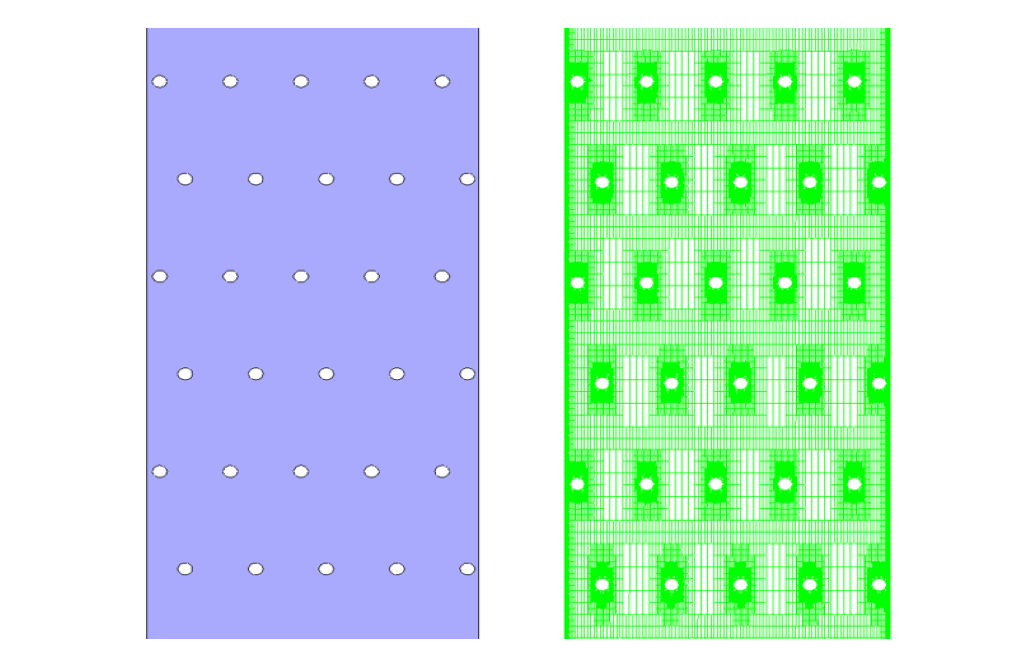

The present model is designed in three dimensions using Design Modeler software. This model includes a three-dimensional chamber that has a height of 0.14 m and has 48 rows of holes as metal wire mesh, in each row, there are 5 holes. Since this model has geometric symmetry, the lateral aspects of the model are defined as symmetry. We carry out the model’s meshing using ANSYS Meshing software. The mesh type is structured. The element number is 186933. The following figure shows the Mesh.

Wire Mesh CFD Simulation

We consider several assumptions to simulate the present model:

- We perform a pressure-based solver.

- The simulation is steady.

- The gravity effect on the fluid equals -9.81 m.s-2 along the Y-axis.

The following table represents a summary of the defining steps of the problem and its solution:

| Models | |||

| Viscous | k-epsilon | ||

| k-epsilon model | standard | ||

| near-wall treatment | standard wall function | ||

| Multiphase model | Eulerian | ||

| dense discrete phase model | On | ||

| number of eulerian phases | 1 | ||

| number of discrete phases | 1 | ||

| Discrete Phase Model | Interaction with Continuous Phase | ||

| Energy | On | ||

| Boundary conditions | |||

| Inlet | Velocity Inlet | ||

| discrete phase BC type | escape | ||

| primary phase | velocity magnitude | 2, 3, 4 m.s-1 | |

| temperature | 373.15 K | ||

| Outlet | Pressure Outlet | ||

| discrete phase BC type | escape | ||

| gauge pressure | 0 pascal | ||

| Holes | Wall | ||

| wall motion | stationary wall | ||

| heat flux | 0 W.m-2 | ||

| Mirrors 1, 2, 3, 4 | Symmetry | ||

| Methods | |||

| Pressure-Velocity Coupling | Phase Coupled SIMPLE | ||

| pressure | PRESTO | ||

| momentum | first-order upwind | ||

| turbulent kinetic energy | first-order upwind | ||

| turbulent dissipation rate | first-order upwind | ||

| energy | first-order upwind | ||

| Initialization | |||

| Initialization methods | Standard | ||

| gauge pressure | 0 pascal | ||

| primary phase | y-velocity | 2, 3, 4 m.s-1 | |

| temperature | 373.15 K | ||

| discrete phase | y-velocity | 2, 3, 4 m.s-1 | |

| temperature | 373.15 K | ||

| the volume fraction of discrete phase | 0.00001 | ||

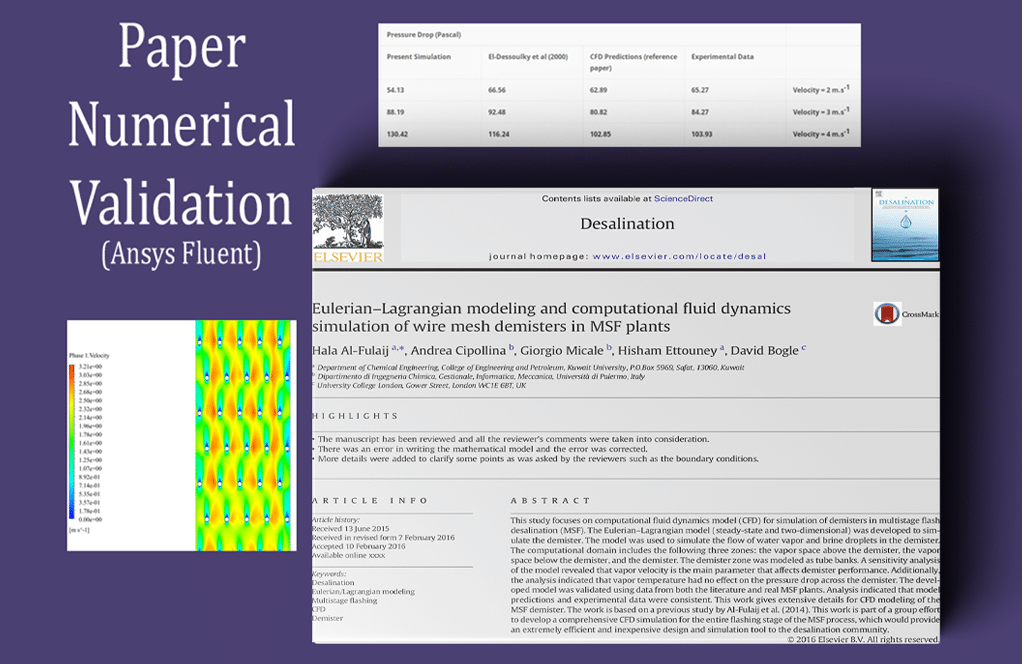

Paper Validation

The validation of the present paper is based on the diagram in Figure 6 of the mentioned article. This graph is related to the changes in the amount of pressure drop between the bottom and top of the demister at different values of the inlet steam velocity. This diagram is related to a situation where the diameter of metal wires equals 0.24 mm. The amount of pressure drop in each inlet steam velocity value is obtained and compared with the results in the article and validated.

| Pressure Drop (Pascal) | ||||

| Present Simulation | El-Dessoulky et al (2000) | CFD Predictions (reference paper) | Experimental Data | |

| 54.13 | 66.56 | 62.89 | 65.27 | Velocity = 2 m.s-1 |

| 88.19 | 92.48 | 80.82 | 84.27 | Velocity = 3 m.s-1 |

| 130.42 | 116.24 | 102.85 | 103.93 | Velocity = 4 m.s-1 |

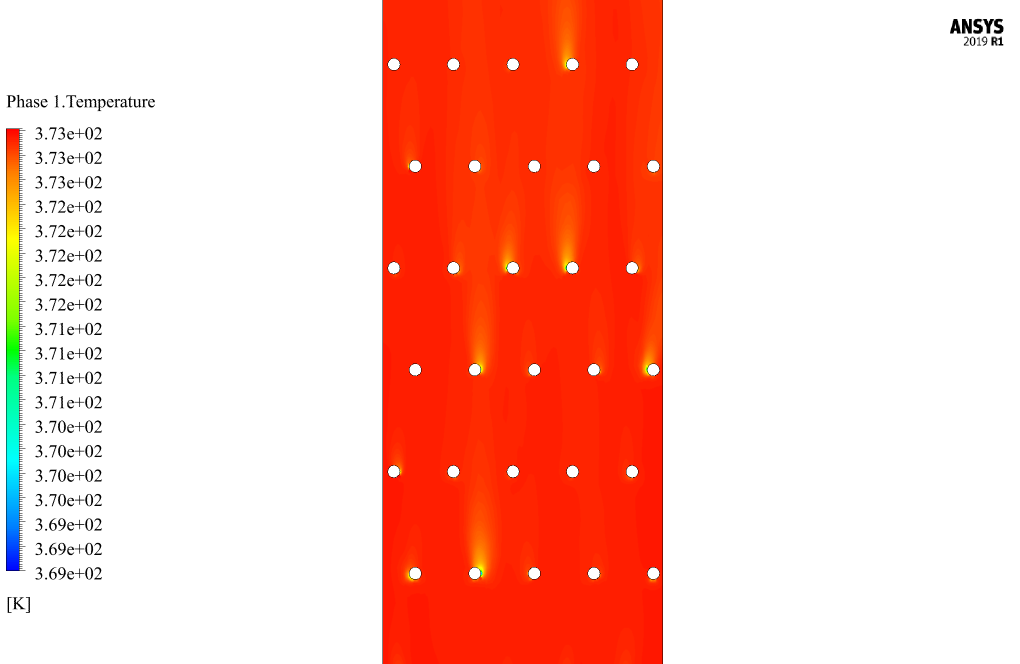

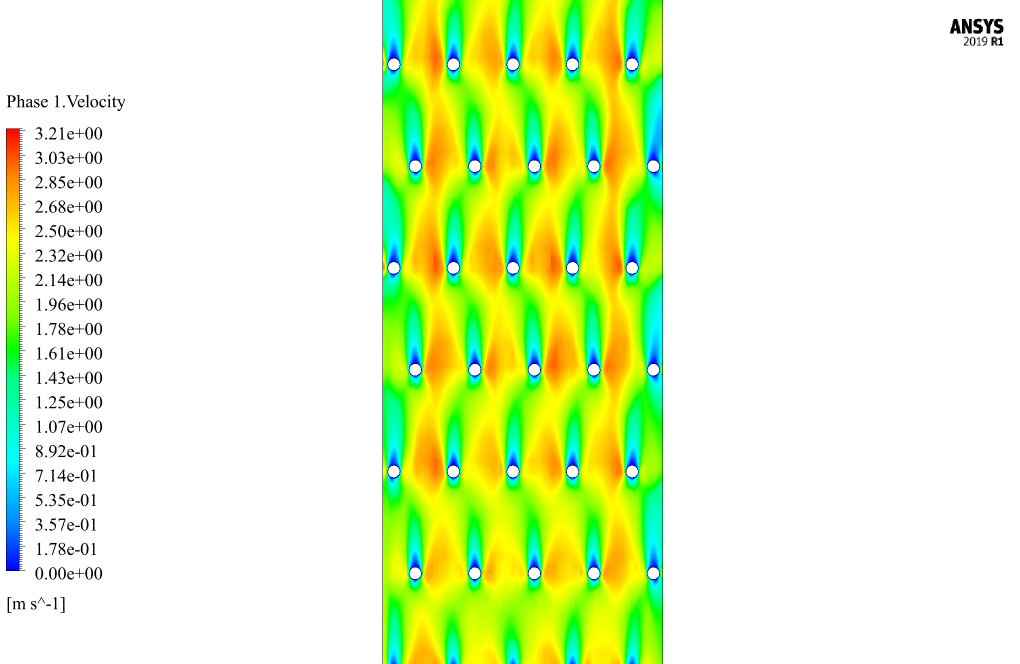

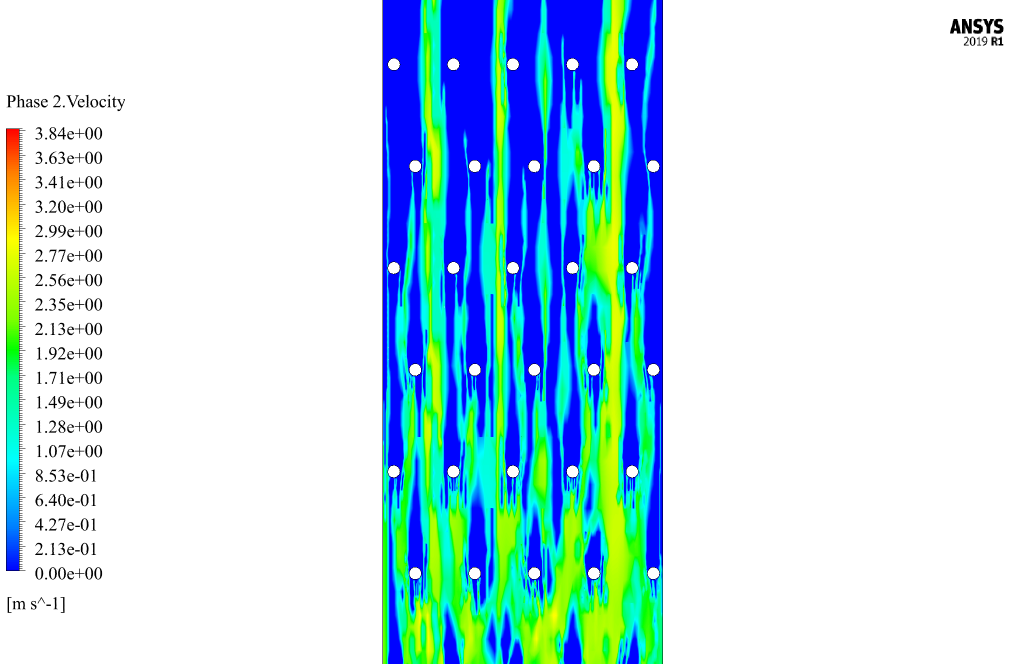

Results

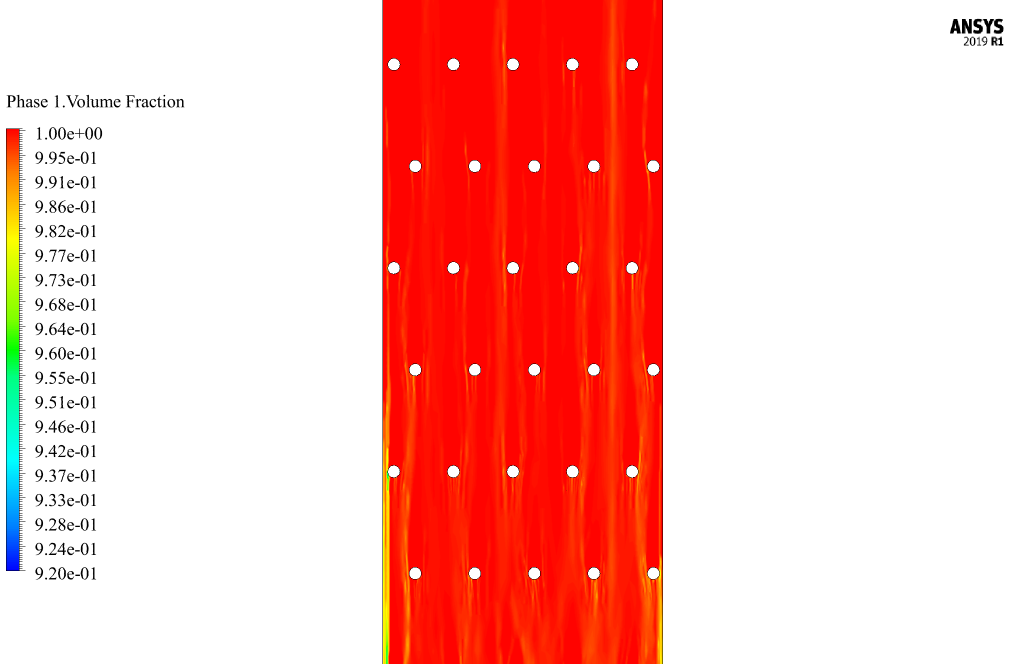

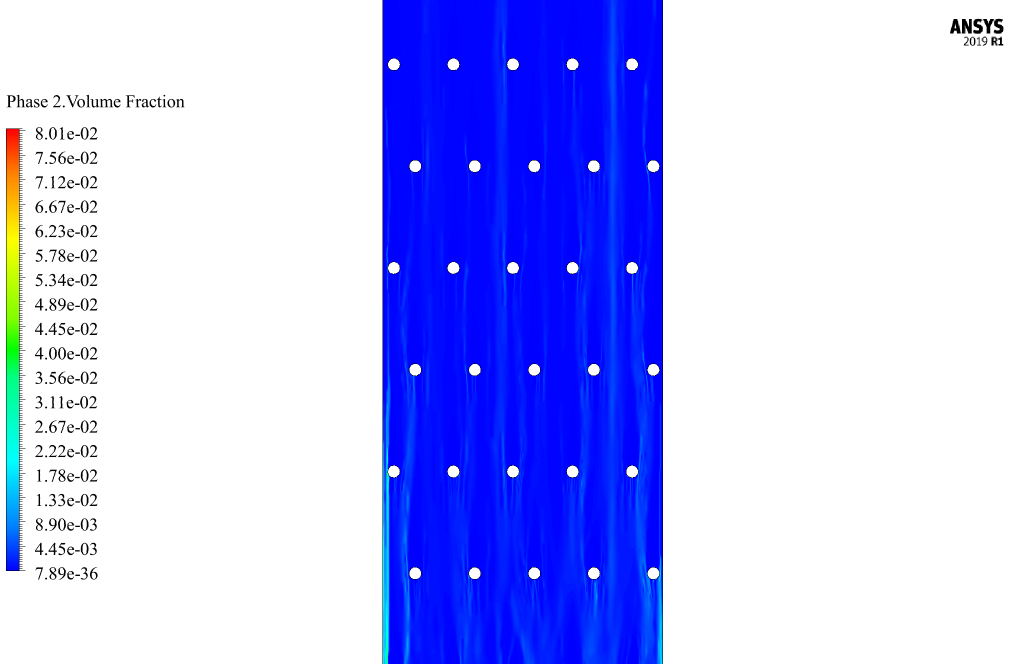

At the end of the solution process, two-dimensional contours related to temperature, velocity, and volume fraction of each continuous (water vapor) and discrete (saline water droplets) phase are obtained. These contours correspond to a state where the incoming steam velocity’s value equals 2 m.s-1. As can be seen from the pictures, as the steam flows upwards, the number of discrete droplets of saline water dissolved in the steam decreases.

Yessenia Parisian –

How does the simulation account for the turbulence in the gas flow?

MR CFD Support –

The simulation uses a turbulence model, such as the k-epsilon or k-omega model, to accurately capture the effects of turbulence on the gas flow and droplet capture by the wire mesh.

Ms. Thelma Hills –

How does the simulation model the interaction between the gas and the wire mesh in the demister?

MR CFD Support –

The simulation uses the Eulerian-Lagrangian approach to model the interaction between the gas and the wire mesh. This approach treats the gas as a continuous phase and the droplets as discrete particles, allowing for an accurate prediction of droplet capture by the wire mesh.

Dr. Merle Reinger DDS –

The simulation setup seems quite comprehensive. Could you explain how the DDPM accounts for the interaction between the water vapor and the saline water droplets?

MR CFD Support –

In this simulation setup, the Dense Discrete Phase Model (DDPM) is used to account for the interaction between the water vapor (continuous phase) and the saline water droplets (discrete phase). Through DDPM, the momentum, mass, and energy exchanges between the droplets and the vapor are accurately captured by considering each droplet as a separate entity within the calculation, while the effects of droplets on the fluid flow and vice versa are also computed. Additionally, DDPM allows tracking of numerous particles, which is essential given the scale of separation processes in a real MSF desalination system.

Mrs. Ona Stoltenberg –

The review highlights excellent simulation accuracy validated against reference data. How challenging was it to calibrate the CFD model parameters to match the experimental results in the article so closely?

MR CFD Support –

Thank you for your compliment! Calibration is indeed a vital part of the simulation process. It involves meticulous tuning of the model parameters, close examination of the mesh sensitivity, and a deep understanding of the physics involved in the process. It may require several iterations and cross-validations with experimental or literature data to ensure the simulation accurately replicates real-world scenarios.

Miss Alexanne Hoeger –

I am truly amazed by how comprehensive this training material is and the depth it provides in validating CFD simulations against experimental data. The focus on detailed descriptions of the methodology along with the paper validation is certainly something that stands out. Kudos to MR CFD for crafting a top-notch ANSYS Fluent CFD training module that’s both practically useful and academically rigorous.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that you’ve found the Wire Mesh Demister CFD training material to be comprehensive and valuable. At MR CFD, we strive to ensure our products serve both practical and academic purposes effectively. Your appreciation truly motivates us to keep up the good work. If you ever have any questions or need further assistance, please don’t hesitate to reach out.

Audie Padberg –

Can you explain further how the stability of the simulation is maintained when using the Eulerian-DDPM method, given the challenge of coupling the continuous and discrete phases?

MR CFD Support –

To ensure stability when using the Eulerian-DDPM approach in the simulation, we employ robust numerical methods such as the Phase Coupled SIMPLE algorithm for pressure-velocity coupling, and PRESTO for pressure interpolation. Additionally, the simulation is also stabilized through the proper initialization of flow fields and choosing first-order upwind schemes for discretization, which may increase the simulation robustness. Careful attention is given to controlling the time step size and convergence criteria to avoid divergence issues commonly associated with coupling discrete and continuous phases.

Christiana Connelly –

This learning product was incredibly precise and informative! I was able to validate my own CFD simulation against the detailed studies from the reference paper. Everything, from the initial conditions to the final results was clearly explained, making it easier to follow and understand the complex demister simulation. Especially helpful were the step by step boundary conditions setup and validation results that matched those from the research paper. MR CFD’s package helped bridge the gap between academic research and practical application wonderfully.

MR CFD Support –

We’re thrilled to hear that you found our Wire Mesh Demister (DDPM) simulation package so beneficial for your validation needs. It’s wonderful to know that the detailed explanations and step-by-step instructions assisted in making the complexities of CFD more comprehensible. Thank you for your positive feedback, and we look forward to continuing to support your simulation endeavors!

Monica Senger DVM –

Do you provide any follow-up support after the course for running similar simulations on other geometries or configurations?

MR CFD Support –

Thank you for your interest in our CFD training course. Yes, after completing the course, we offer follow-up support for your future simulations. Our team is here to assist you if you encounter any challenges when applying the knowledge gained from the course to other geometries or configurations.

Richard Leuschke –

The product sounds comprehensive and very detailed. Just for clarification, an elevated temperature of 373.15 K is specifically mentioned for both the water vapor and saltwater droplets. Is this consistent with simulating actual conditions in demisters used in MSF desalination systems?

MR CFD Support –

Yes, in our simulation, we use a temperature of 373.15 K for both the water vapor and saltwater droplets because it closely matches the operating conditions typically found in Multi-Stage Flash (MSF) desalination systems. These conditions are particularly relevant for ensuring that the results are realistic and that the simulation effectively serves as a tool for studying and improving demister designs.

Amir Muller –

How precisely does the simulation’s pressure drop data match the experimental values provided in the reference paper? Are the discrepancies significant in any way?

MR CFD Support –

The pressure drop data from the simulation shows close agreement with the experimental values from the reference paper. The discrepancies observed are within an acceptable range, indicating that the simulation accurately captures the essential physics of the demister.

Zoe Hegmann –

The provided details are comprehensive, but I wonder whether the simulation includes the potential for salt accumulation on the wire mesh over time?

MR CFD Support –

During this steady-state simulation, the focus is on analyzing the immediate effects of the water vapor and saline water droplets passing through the demister. Accumulation effects like salt deposition over time are not typically included in a steady-state scenario. However, for a dynamic and time-dependent analysis of salt build-up, which would demand a transient analysis approach, separate modeling consideration would be required to capture the accumulation phenomenon.

Jace Satterfield –

Can the simulation model the effects of different wire mesh designs on the demister’s performance?

MR CFD Support –

Yes, the geometry of the wire mesh in the simulation can be easily modified to study the effects of different wire mesh designs on the demister’s performance.

Prof. Oma Brown –

The simulations show impressive detail especially in the pressure drop analysis, which complements my own study. Excellent reference for future projects!

MR CFD Support –

We’re delighted to hear that our simulations are proving to be a valuable asset in your studies. Thank you for your kind words and for recognizing the effort put into detailed pressure drop analysis. We’re always here to provide quality simulations for your future projects!

Prof. Sonny Anderson DVM –

I used the Wire Mesh Demister CFD training for a project, and it was perfect for understanding DDPM modeling. The step-by-step approach helped me a lot.

MR CFD Support –

Thank you for your valuable feedback! We’re thrilled to hear that our CFD training on Wire Mesh Demister using DDPM modeling was beneficial for your project. It’s always our aim to provide clear and detailed guidance to assist in understanding complex concepts. Your success with your project is a testament to our dedication to quality education. If you need any further assistance or have more projects in the future, do not hesitate to reach out to us.

Tess Koss III –

I completed the training on Wire Mesh Demister (DDPM) using ANSYS Fluent. In your simulation setup, I noticed the specific energy interaction is turned on between the continuous and discrete phases. Could you explain further how this energy exchange takes place and how critical it is to the accuracy of this simulation?

MR CFD Support –

In the simulation, the energy exchange between the continuous phase (water vapor) and the discrete phase (saline water droplets) is accounted for, due to which the temperature of both phases can change during interaction. It’s critical for accuracy as it helps in mirroring real-world physics where energy transfer occurs due to factors like condensation and evaporation, which in turn can affect the temperature and flow characteristics in the demister.

Rowland Ebert –

Amazing resource for validating computational models against experimental data. It’s very clear that a lot of effort has gone into ensuring the accuracy of the simulation results to reflect real-life applications. Does the package come with benchmark test cases for additional practice?

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our product is assisting you effectively in your CFD simulations. Regarding your inquiry, our training package comes equipped with several example cases which serve to solidify the user’s understanding of the simulation process. These examples are tailored to simulate real-world scenarios and provide a comprehensive learning experience.

Troy Fritsch –

Thank you for the detailed explanation of the Wire Mesh Demister simulation and its validation based on the reference paper. The methodology and results are well-explained, and comparing the pressure drop from the simulation to the experimental data is impressive.

MR CFD Support –

Thank you for your positive feedback on the Wire Mesh Demister CFD simulation tutorial. We’re really glad to hear that you found the explanation detailed and the comparative analysis with experimental data helpful. If there’s anything else you’d like to learn or more support you need regarding CFD training, we’re here to help!

Alexandria Littel II –

Extremely thorough and informative. Amazing to see the validation against experimental data—this level of detail ensures confidence in the simulation process.

MR CFD Support –

Thank you for your kind words! We strive to provide detailed and accurate simulations to support learning and enhance understanding. We’re glad to hear that the validation data was helpful for confidence in our process.

Prof. Bret Nitzsche –

I’m thoroughly impressed by the validation process using CFD predictions and experimental data. Can you explain how the volume fraction of discrete phase was initially determined in the simulation setup?

MR CFD Support –

To ascertain the volume fraction of the discrete phase initially in the simulation, refer to empirical data from the reference article or established theoretical estimations for such systems. The specified value promotes accuracy in capturing the dynamics of the multiphase flow throughout the simulation, ensuring that results closely match those of real-world scenarios and experimental findings.

Malika Kunde –

The learning material’s balance between technical detail and accessibility is truly commendable. Examples and charts, especially the comparison with experimental data,… provide an excellent means of grasping the practical implications of the simulations. Applying the DDPM in tandem with the Eulerian model clarified multiphase flow complexities well. I’m eager to see future materials that delve into unsteady simulations or explore further the impact of demister design changes on efficiency.

MR CFD Support –

Thank you for taking the time to provide your feedback, we’re thrilled to hear that you found the training material both informative and approachable. We always strive to present complex concepts in a way that is accessible to learners at various levels. Your interest in unsteady simulations and design impacts is noted, and we are looking forward to bringing more comprehensive learning materials in the future. Stay tuned for upcoming training content!

Lorna Frami –

The detail is incredible in this review. What was the most challenging part about the simulation process based on the comparison with the reference paper?

MR CFD Support –

From the simulation standpoint, accurately coupling the Eulerian and Lagrangian models to predict the pressure drop and the interaction between the water vapor and saline water droplets was probably the most challenging. Ensuring the results align with the experimental data from the reference paper required precise parameter and boundary condition setup. The process necessitated meticulous attention to the mesh quality around the wire mesh demisters as it directly influences the accuracy of the pressure drop predictions.